WEBINAR

Deep Groove Ball Bearing

Learn MoreThe application of bearings in aerospace is crucial. They not only ensure the efficient operation of mechanical systems, but also play a decisive role in improving the safety and reliability of the overall mission.

By withstanding extreme loads, speeds and environmental conditions, bearings enable critical aerospace vehicle components to operate at optimal performance, such as engines, navigation systems and controls. Their high-precision design and manufacturing can reduce friction and improve energy efficiency while maintaining system stability and precise control.

In addition, lightweight solutions for bearings have an important impact on reducing aircraft weight, improving fuel economy, and extending operating range.

In general, the technological progress and application of bearings have provided strong support for the development of the aerospace field, enabling it to meet more complex and challenging tasks.

Aerospace bearings are designed to withstand extreme loads and high speed operations, especially in aircraft engines and turbines. They must be able to maintain performance during sustained high-speed rotation while handling significant axial and radial loads.

Aerospace bearings are frequently exposed to extreme temperatures, from cryogenic environments during high-altitude flight to high-temperature conditions inside engines. Therefore, these bearings often use special materials and coatings, such as high-temperature alloys and ceramic materials to ensure performance and longevity under these conditions.

Since aircraft often operate in changing environments, including humid and salt spray environments, aviation bearings need to have excellent corrosion resistance. In addition, they should be resistant to wear and fatigue that may occur during long periods of operation.

In order to reduce the overall weight of the aircraft and improve fuel efficiency, aviation bearings adopt lightweight designs. Through the use of lightweight materials and optimized structural design, the bearings contribute to overall weight reduction and performance improvement.

Bearings in the aerospace industry are designed with ease of maintenance to reduce downtime and maintenance costs. Some bearings adopt self-lubricating technology to reduce the need for lubrication maintenance.

Considering the special needs of the aerospace sector, many bearings are customized for specific applications to ensure optimal performance. These customized solutions involve special designs, material selections and processes to suit specific operating conditions and performance requirements.

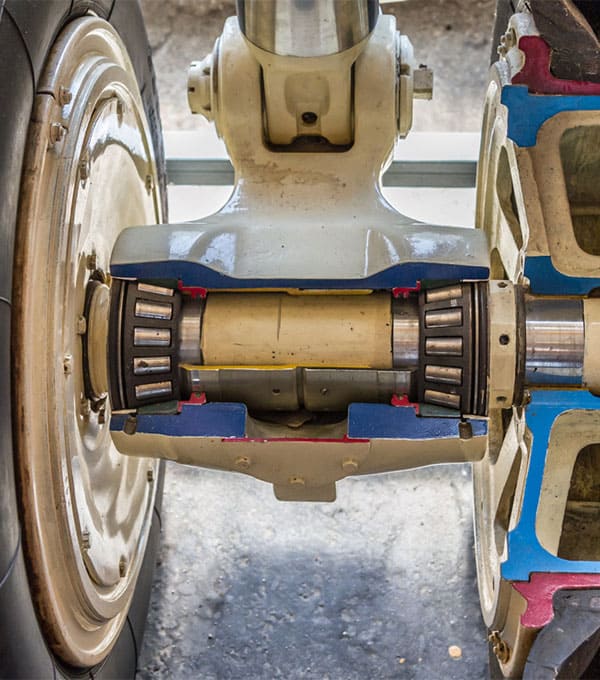

Bearings play a vital role in aircraft landing gear design, with design features and functions specifically tailored to meet the stringent demands of the aviation sector. Landing gear bearings are designed to withstand extreme loads and impacts, ensuring they absorb huge impacts when the aircraft lands and provide stable support during takeoff and taxiing.

These bearings usually use high-strength, corrosion-resistant materials, such as special alloy steel or high-performance composite materials to cope with complex environmental conditions. Their design also includes high load carrying capacity and low friction properties to reduce energy losses and increase efficiency.

To reduce maintenance requirements and extend service life, landing gear bearings tend to have self-lubricating properties to reduce the need for periodic maintenance. Lightweight is also an important design to help to reduce the overall weight of the aircraft and thus improve fuel efficiency. These design features make bearings a critical component in ensuring the reliability, safety and economy of landing gear systems.

● Type of Bearing: Tapered roller bearing.

● Features: Adjust internal design can adapt to different loads and usage conditions, which provides flexible design options.

● Advantages: It can bear both the large radial and axial loads at the same time, and is suitable for bearing complex load conditions.

In aircraft control systems, the design features and functions of bearings are crucial to ensure the accuracy and reliability of flight control. These bearings often require extremely high precision and low friction properties to allow pilots to make fine adjustments to the aircraft's direction, altitude and speed. They play a role in key parts such as joysticks, pedals and control surface hinges to make the response of the flight control system more sensitive and accurate.

When designing, the bearings use high-strength, wear-resistant materials, such as special alloys or high-performance composite materials to adapt to dynamic loads and environmental changes during flight. The self-lubricating property is an another important feature of these bearings, which reduces maintenance requirements and increases service life.

● Type of Bearing: Needle roller bearing.

● Features: Compact design suitable for use in flight control systems with limited space, such as joystick attachment points.

● Advantages: It can withstand high loads, especially providing maximum load-bearing capacity in limited radial space.

The application of bearings in spacecraft design is critical, as they must adapt to the extreme conditions of the space environment, such as vacuum, radiation, temperature fluctuations and microgravity.

These bearings are specially designed to withstand long-term space missions without compromising their performance. Spacecraft bearings often use advanced materials, such as special alloys and ceramics to enhance their corrosion resistance, wear resistance and reduce friction, ensuring they can operate effectively in a space environment without an atmosphere.

In addition, many spacecraft bearings are designed to be self-lubricating or use solid lubricants to avoid performance degradation in environments where routine maintenance is not possible. The functions of bearings on spacecraft include supporting the positioning of solar panels, adjusting the direction of antennas, ensuring the precise pointing of instruments, and controlling the spacecraft's navigation system. Lightweight design is also a major feature of spacecraft bearings, which helps to reduce launch costs and improve load efficiency.

● Type of Bearing: Angular contact ball bearing.

● Features: Provide a high degree of accuracy and speed capabilities, often used in satellite solar panel drive systems and high-precision instruments.

● Advantages: It can withstand both large radial loads and axial loads at the same time, and is especially suitable for applications that bear combined loads.

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

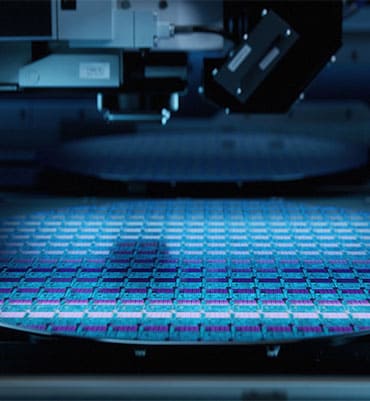

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation