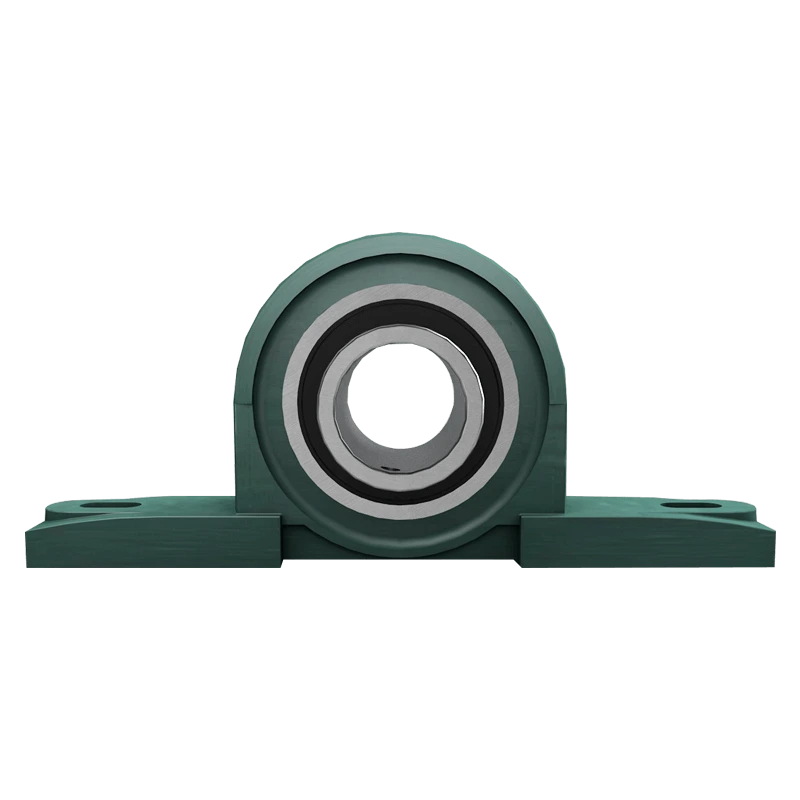

Pillow block bearing is a component that supports the bearing and protects it from external influences, and is often used to hold the bearing in place to ensure its correct operating positioning.

Compatible Design: The design of the housing is usually adapted to a specific type of bearing, such as ball bearings, roller bearings, etc., to ensure that the bearing can be properly installed and operated.

Material Selection: Typically made of cast iron or cast steel for sufficient strength and rigidity, stainless steel or plastic may also be used in some applications to suit specific environmental conditions.

Installation and Fixing Methods: There are a variety of installation methods, such as base type, flange type, hanging type, etc., to adapt to different installation needs.

Sealing System: Equipped with appropriate seals, such as oil seals and cover plates, to prevent dust, moisture and other impurities from entering and protect the bearing from contamination.

Industrial Production Equipment: Bearing housings are used to fix bearings in these equipment such as conveyor belts, motors, fans, etc., to ensure the smooth operation of mechanical components.

Automotive Industry: It is widely used in the transmission system and suspension system of automobiles to provide stable bearing support.

Agricultural Machinery: In agricultural equipment such as tractors and harvesters, bearing housings help withstand the challenges of high loads and rough environments.

Construction Machinery and Heavy Equipment: In heavy machinery such as excavators and cranes, bearing housings need to withstand extreme working conditions and heavy loads.

Easy to Install and Maintain: The housings are designed for quick installation and removal, simplifying the maintenance process and reducing maintenance costs.

Adaptability: Some designs allow the position of the bearing to be fine-tuned after installation for optimal operation.

Load Carrying Capacity: Designed with sufficient strength and rigidity to support the load on the bearing and extend the life of the equipment.

Diverse Sealing Options: Provide a variety of sealing solutions to meet the challenges of different environments, such as dustproof, waterproof, anti-corrosion, etc.

Bearing Protection: Prevent external factors such as dust and moisture from invading the inside of the bearing, and prolong the service life of the bearing.

Ensure Stability and Accuracy: Provide a stable mounting base for the bearings to ensure the operational accuracy and reliability of the mechanical system.

Adaptability: Adapt to a variety of complex and harsh environments to ensure the continuous operation of machinery and equipment under different conditions.

Ease of Maintenance: Designed with ease of maintenance in mind, reducing downtime and repair costs.

● SKF (Sweden)

● Timken (USA)

● NTN (Japan)

● FAG (Germany)

● NSK (Japan)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation