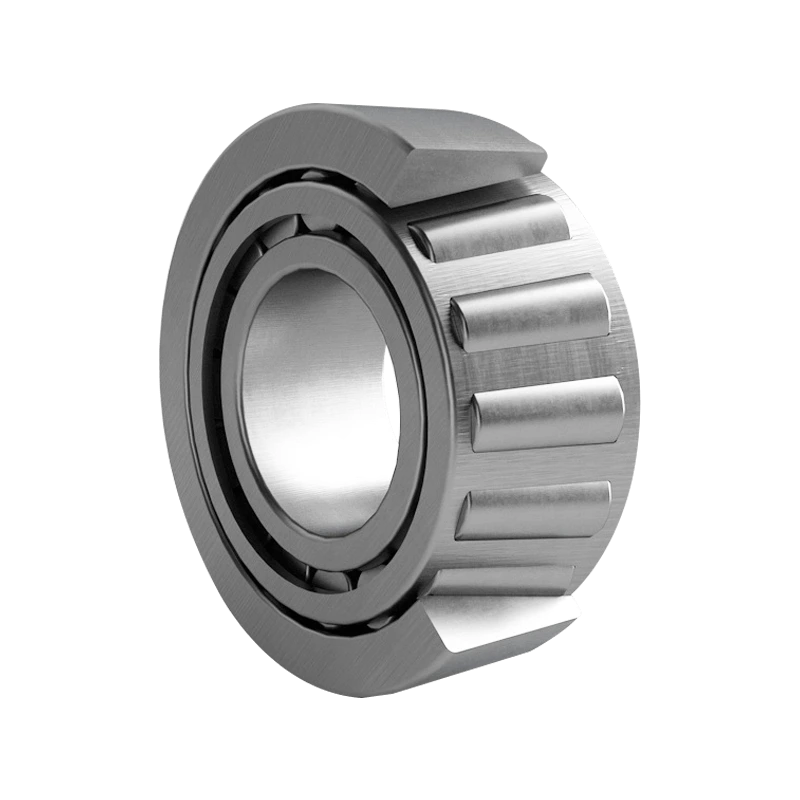

Tapered roller bearings are a commonly used type of bearing, which designed to withstand both radial and axial loads. They are very popular in a wide variety of industrial applications, especially where high reliability and durability are required.

Conical Rollers: The bearing rollers are conical in shape, which allows for an efficient dispersion of radial and axial loads from the bearing.

Inner and Outer Rings: The inner ring (taper) and outer ring (cup) have conical raceways that match the shape of the rollers and provide a contact surface.

Cage: Tapered roller bearings are equipped with cages to maintain uniform spacing and stable arrangement of rollers, and improve the overall stability and efficiency of the bearing.

Adaptability: The internal design of the bearings allows for fine adjustments during installation and optimize load distribution and extend service life.

Automotive: Widely used in axles, transmissions, and differentials in trucks to withstand heavy loads and shocks.

Industrial Machinery: Used in transmission systems, gear units and other load-bearing mechanisms, especially in machines with complex or variable load conditions.

Agricultural Equipment: In tractors and harvesters, it is subjected to heavy loads and the effects of the external environment.

Wind Power: Tapered roller bearings are used in the spindles and gearboxes of wind turbines to cope with high loads and variable speed conditions.

High-Load Carrying Capacity: Its structural design allows the bearing to maintain stability and efficiency while bearing high radial and axial loads.

Impact Resistance: The shape of the tapered rollers helps disperse the impact force and increases the durability of the bearing in harsh environments.

Adaptable to Different Loads: By selecting different sizes and designs of tapered roller bearings, you can the optimized the load distribution for different applications.

Maintainability: While these bearings may require regular maintenance, their construction allows for an easier installation and disassembly for inspection and replacement.

Improve Load Efficiency: Performance and duration under complex loads are improved by optimizing the bearing design.

Adapt to Harsh Environments: Specially designed materials and sealing systems allow bearings to operate in dust, contamination and moisture environments.

Reduce Maintenance Requirements: Designed with ease of maintenance in mind, helping the users reduce long-term operating costs.

Improvement of Overall Mechanical Performance: Enhance the performance and reliability of the entire mechanical system by providing reliable bearing solutions.

● Timken (USA)

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● NTN (Japan)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation