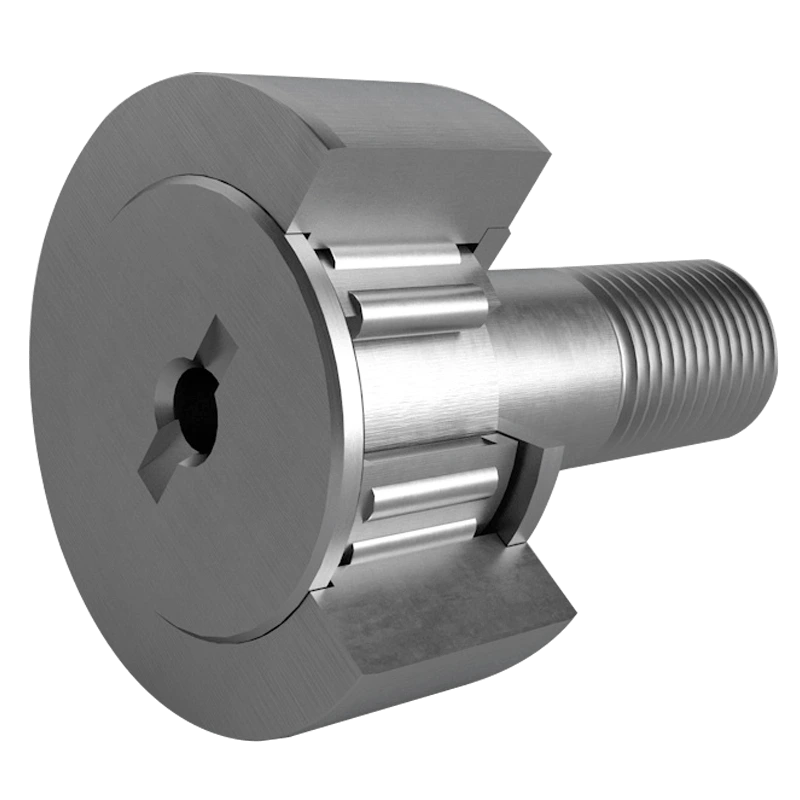

Cam Follower Roller Bearing is a special design that combines bolts and roller bearings. It is often used in specific industrial applications to provide smooth movement and high load capacity.

The structural features of Cam Follower Roller Bearings can be summarized as follows:

Integration of Track Roller and Bolt: The core design of this bearing combines the track roller element with the bolt, allowing it to provide both axial and radial support while also offering low friction and high efficiency during rotation.

Multi-component Structure: Typically composed of a bolt, track roller, cage, and external sleeve. There is a gap between the track roller and the sleeve, with the cage maintaining the relative position of the tack rollers.

Sealed Design: Many Cam Follower Roller Bearings are equipped with sealing devices to prevent dust and debris from entering the bearing, ensuring long-term stable operation.

Self-aligning Feature: Due to its special structure, the Cam Follower Roller Bearing can adapt to installation errors through a self-aligning design, which improves the flexibility and stability of assembly.

High Load Capacity: The track rollers are usually made from high-strength steel materials, which enable them to withstand significant loads and impacts.

The Cam Follower Roller Bearing is typically used in environments requiring high load-bearing capacity and stable motion. Common application environments include:

Heavy Machinery: Such as cranes, excavators, and handling equipment, used for supporting and guiding the smooth movement of heavy loads.

Conveyor Systems: In high-speed and high-load conveyor systems, the Cam Follower Roller Bearing provides smooth rolling support, and reduce friction and wear.

Industrial Automation Equipment: Used in various automation devices and production lines, ensuring smooth linear and rotary motion.

Automotive Industry: Cam Follower Roller Bearings are commonly used in suspension systems, drive systems, and other automotive applications, providing high-load resistant motion support.

Construction Machinery: Such as excavators, bulldozers, and other large machines, where the bearings are used to carry loads and reduce friction in moving parts, extending the equipment's lifespan.

Agricultural Machinery: Such as tractors and harvesters, where the Cam Follower Roller Bearings are used in high-load operating environments.

Combination of Track Roller and Bolt: The key feature of this design is the combination of the track roller and bolt, which can provide both axial support and rotational movement, reducing the complexity of components.

High Load Bearing Capacity: Due to the use of roller elements, it can withstand larger loads and still maintain good motion stability under high load conditions.

Low Friction and High Efficiency: Compared to traditional sliding supports, Cam Follower Roller Bearings offer lower friction, reducing energy loss and improving efficiency.

Wear Resistance: The structure of track roller distributes the contact area over a larger surface, reducing single-point friction, minimizing wear, and improving bearing durability.

Sealed and Dust-Proof Design: Many Cam Follower Roller Bearings use a sealed design to prevent dust, moisture, and debris from entering the bearing, thereby enhancing service life.

High Load Capacity and Stability: Cam Follower Roller Bearings provide high load capacity, especially suitable for high load, heavy object transmission and high impact conditions.

Low Friction and Long Service Life: With the combination of track rollers and bolts, bearings have a low friction coefficient, resulting in high operational efficiency, reduced wear, and extended service life.

Space-Saving and Simplified Structure: By combining the bolt and track roller in one design, the bearing simplifies installation and design, saving space.

Strong Adaptability: They generally have excellent anti-pollution ability and can function in harsh environments, such as high temperatures, humidity, and dusty conditions.

Self-aligning Capability: The bearing structure typically includes a self-aligning feature, which can compensate for certain installation errors and reduce failures caused by assembly issues.

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● INA (Germany)

● Timken (USA)

● RBC Bearings (USA)

● JTEKT (Japan)

● Kitanihon Seiki (Japan)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

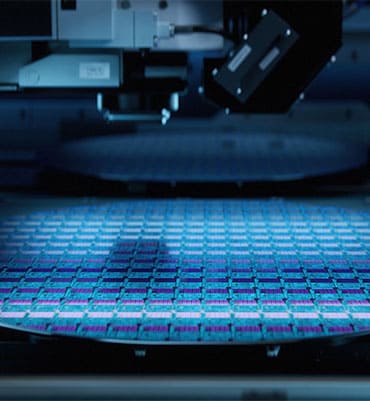

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation