Collaborating With WEEYH

WEEYH maintains close cooperation with China's top bearing research institute to provide high-quality bearings to global dealers.

In bearing production, quality control is not only the cornerstone to ensure product performance and reliability, but also the key for WEEYH to win market trust, reduce customer operating costs and enhance customer competitiveness. Through strict quality control processes, from raw material inspection to finished product inspection, ensuring that each bearing meets high-standard quality requirements can significantly extend the service life of the bearing and reduce maintenance costs and downtime losses caused by failures.

Covering all stages from raw material procurement, production process,

final product testing before leaving the factory:

Strict inspection of raw materials (such as bearing steel, grease, etc.) to ensure that they meet standard requirements.

Analyze the material composition to confirm that the proportion of alloy elements meets specifications.

Ensure that all manufacturing processes (such as heat treatment, grinding, assembly, etc.) strictly comply with process standards and operating procedures.

Real-time monitoring of key parameters in the production process, such as temperature, pressure, speed, etc. to ensure process stability.

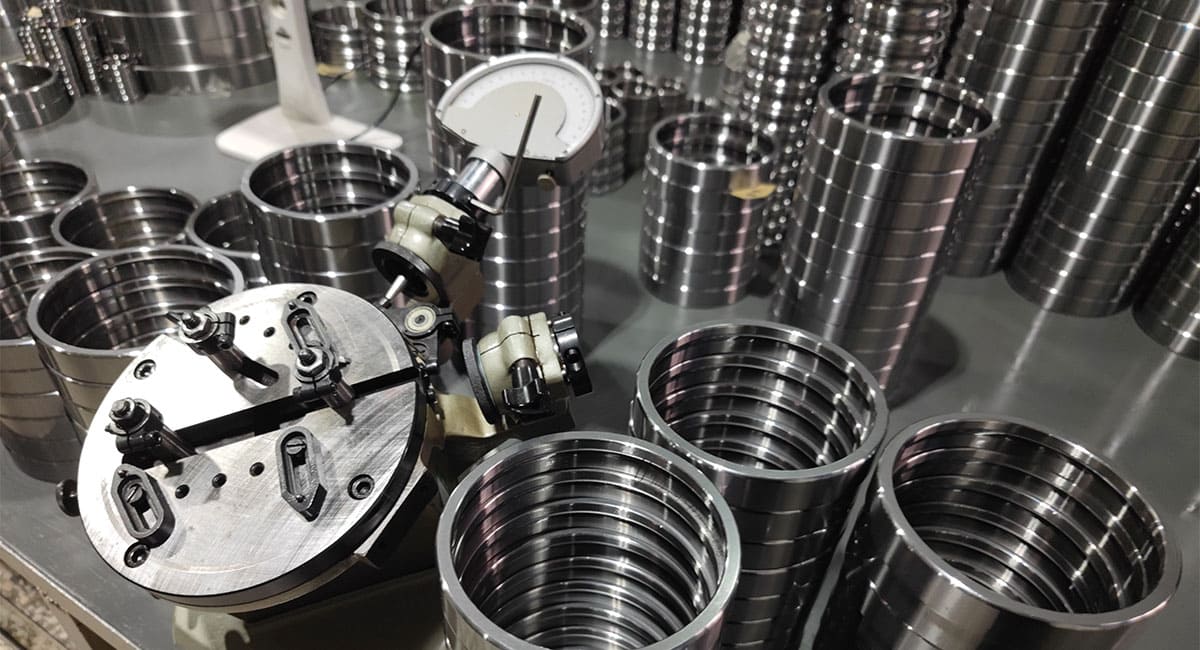

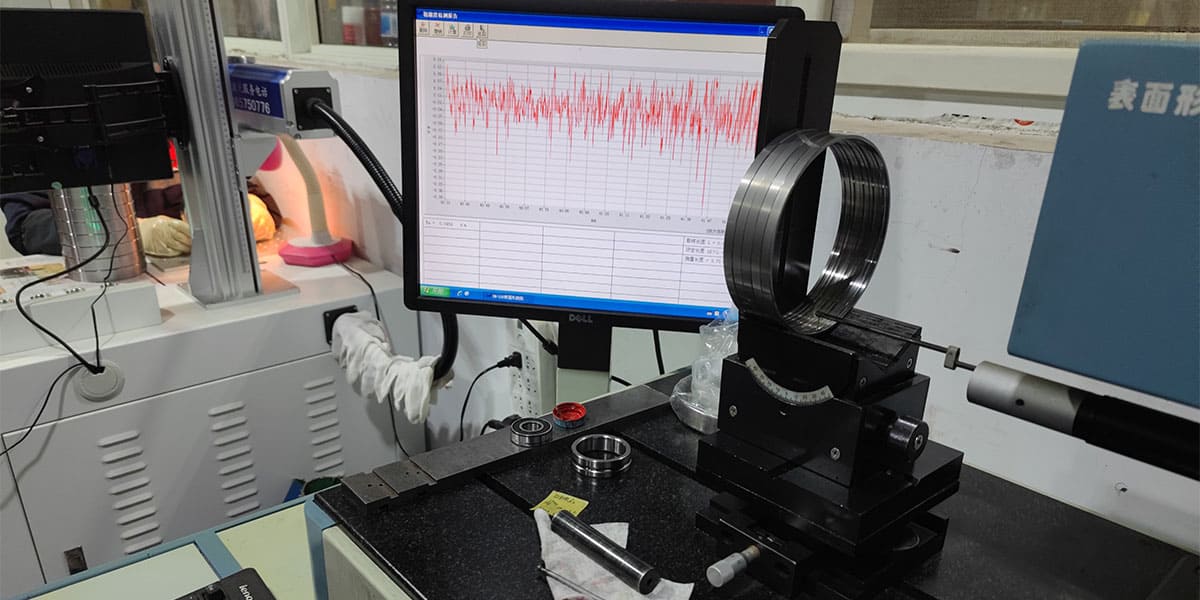

Use precision gauges and equipment (such as micrometers, roundness meters, etc.) to check the dimensional accuracy and Geometric tolerance of the bearings.

Checking the appearance of the bearings to ensure that there are no scratches, cracks, rust and other defects.

Test the performance of bearings under specified loads, including load carrying capacity and life prognosis.

Evaluate the vibration and noise levels of bearings during operation to ensure compliance with standards.

Check that the type, quantity and lubrication effectiveness of the lubricant can meet the design requirements.

Test whether the sealing system of the bearing is effective in preventing lubricant leakage and contaminant ingress.

Ensure that the packaging of the bearings can provide sufficient protection against damage during transportation.

Check whether the storage environment of the bearings can meet the requirements to avoid damage caused by humidity, temperature and other factors.

Record the production and inspection data of each batch of bearings in detail to facilitate quality traceability.

Establish customer feedback mechanism, analyze the quality problems received and formulate measures of improvement.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation