WEBINAR

Deep Groove Ball Bearing

Learn MoreIn the semiconductor industry, the accuracy, stability and reliability of bearings are critical to the overall manufacturing process. Semiconductor manufacturing equipment, such as photo-lithography, wafer processing machines and assembly machinery, rely on high-performance bearings for precise and efficient operation. These bearings must be able to operate at high speeds and with high accuracy, while resisting the effects of fine particles and chemical corrosion.

The primary role of bearings in the semiconductor manufacturing process is to ensure smooth, precise movement of equipment components to enable fine handling of wafers. Any bearing failure or performance degradation can lead to product quality issues and even costly downtime. Therefore, the high precision and long-term stability of bearings are critical to maintaining line continuity and raise production.

In addition, as semiconductor technology moves toward the direction of higher integration and smaller sizes, the demand for bearings is rising. Advanced bearing technologies, such as air bearings and high-precision miniature bearings, are becoming critical to achieving finer processing and higher productivity.

In summary, bearings is not only the basis to ensure the normal operation of the equipment in the semiconductor industry , but also to promote the industry's technological progress and improve manufacturing efficiency is an important factor.

Optimization and Innovation of the bearings are critical to meeting the higher demands for precision and reliability in the semiconductor industry, while also having a profound impact on reducing operating costs and improving product quality. The developments of bearing technology will largely impact on how well the semiconductor industry to respond to growing market demands and increasingly demanding manufacturing standards.

Semiconductor manufacturing requires equipment with extremely high positioning accuracy and repeatability, so the bearings used in these applications must be able to provide extremely high movement accuracy to ensure that the equipment can accurately handle tiny semiconductor components.

In order to achieve high-precision motion control, bearings need to have extremely low friction coefficients and vibration levels, which helps improve the stability of equipment and the quality of the manufacturing process.

Semiconductor manufacturing processes need to take place in an extremely clean environment to prevent tiny particles from contaminating the wafers. Therefore, bearings must be compatible with clean room environments, not generate contaminants, and be able to function properly in dust-free conditions.

A variety of chemicals and corrosive gases are used in the semiconductor manufacturing process. Bearing materials and lubricants need to have good chemical stability to resist attack by these chemicals.

Certain semiconductor equipment, such as machines that rotate wafers, requires bearings that can operate stably at high speeds while maintaining high accuracy and low heat generation to avoid thermal damage to sensitive semiconductor materials.

Considering the high cost of semiconductor manufacturing equipment and the need for production continuity, bearings need to have a long service life and extremely high reliability to reduce downtime and maintenance costs.

Due to the particularity and complexity of the semiconductor manufacturing process, bearings often need to be customized according to the needs of specific applications to meet specific performance requirements.

In some semiconductor equipment, bearings must be able to operate stably within a controlled temperature range, because temperature fluctuations may affect the accuracy of the equipment and the quality of semiconductor products.

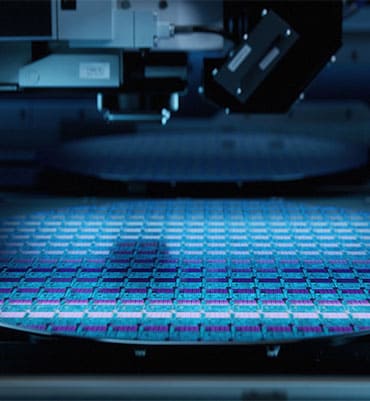

In semiconductor wafer fabrication equipment, the accuracy, stability and reliability of bearings are critical to the overall manufacturing process. Wafer fabrication involves multiple high-precision and high-purity steps such as dicing, grinding, polishing and lithography. During these processes, bearings are used to support and guide the precise movement of wafers and processing heads, ensuring that each step of the manufacturing process is accomplished with extreme precision!

High-performance bearings are essential for wafer fabrication equipment. They need to have extremely low coefficients of friction and high running accuracy to minimize vibration and heat generation which prevent damage to tiny semiconductor structures. In addition, these bearings must be able to operate stably in clean-room environments, resisting particulate contamination and chemical corrosion which can maintain the purity of the production environment.

● Type of Bearing: High Precision Angular Contact Ball Bearings, Deep Groove Ball Bearings.

● Features: High precision and low friction for high speed rotation.

● Advantages: Improved machining accuracy, reduced heat and vibration.

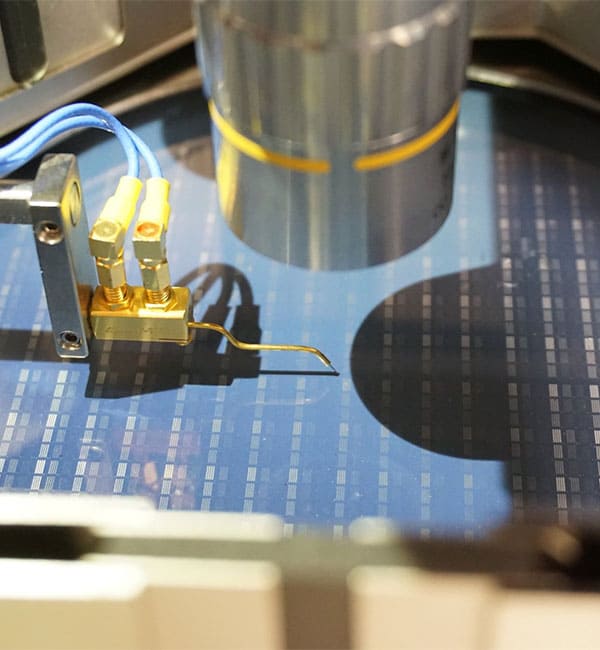

In the semiconductor manufacturing process, a photo-lithography machine is an important equipment used to accurately pattern miniature circuits on wafers. The role of the bearings in this process is to ensure that the mechanical components, especially the lithography head and wafer table, are positioned precisely and move smoothly. The bearings in a lithography machine must have extremely high precision and low friction characteristics to minimize any vibrations or deflections that could lead to pattern deviations.

These bearings are typically high-precision crossed roller bearings or air bearings that provide a high degree of stability and precise motion control, which is critical for achieving Nano -Scale engraving accuracy. In addition, the bearings need to have good durability and reliability for long periods of continuous operation and to resist chemical corrosion and particle contamination in clean room environments.

● Type of Bearing: crossed roller bearings, air bearings.

● Features: Extremely high stability and positioning precisely.

● Advantages: Ensure the accuracy of the lithography process and improve wafer quality.

In the semiconductor manufacturing process, assembly machinery plays a important role in precisely fitting tiny semiconductor chips into circuit boards or packages. This process requires a high degree of precision and stability, and bearings are the key component in ensuring that these requirements are met. Bearings in assembly machinery are responsible for supporting and guiding robotic arms or other moving parts to ensure they are can be precisely positioned and move smoothly, enabling fine manipulation of miniature components.

These bearings are usually high-precision small balls or linear bearings with extremely low coefficients of friction and a high degree of motion accuracy. These characteristics are critical to minimizing vibration, preventing the damage of component, and improving assembly quality. In semiconductor assembly process, even small errors can lead to chip damage or performance degradation, so the high accuracy and stability of the bearings are critical to ensuring the quality and efficiency of the entire assembly process.

● Type of Bearing: cylindrical roller bearings, angular contact ball bearings.

● Features: Withstand loads in different directions, high rigidity.

● Advantages: Ensures the stability and efficiency during the assembly process.

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation