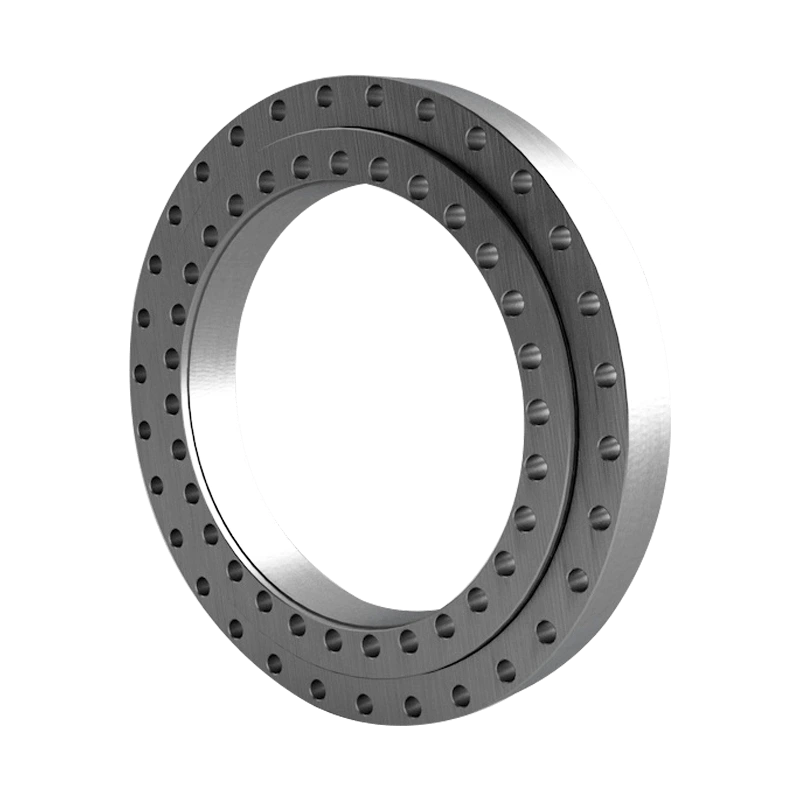

Slewing bearings are large bearings that can withstand large axial and radial loads and tipping moments. They are particularly suitable for applications that carry heavy loads and provide structural rotation.

Round Design: Slewing ring bearings are usually large ring structures with inner and outer rings filled with rolling elements such as balls or rollers.

Rolling Elements: Spherical or cylindrical rollers can be distributed in specific tracks to support compound loads (axial, radial, and tipping moments).

Sealing Systems: To protect bearings from dust, water and other contaminants, they are often equipped with efficient sealing systems.

Gear System: Many slewing ring bearings are designed with internal or external teeth to facilitate rotation through the gear system.

Construction Machinery: Such as excavators, tower cranes, and mobile cranes, which need to withstand heavy loads and perform complex movements.

Wind power: The main bearing used in wind turbines allow the wind turbine to adjust according to the wind direction.

Medical Devices: Used in advanced medical imaging equipment such as CT scanners and radiotherapy equipment, which enables the device to be rotated precisely.

Military & Aerospace: Orientation adjustment systems for radars, tank turrets, and spacecraft.

Versatility: Able to handle many different types of loads at the same time, such as axial loads, radial loads, and tipping moments.

High-Load Carrying Capacity: Designed to withstand extremely high loads, suitable for heavy industrial and engineering applications.

Custom Design: Typically tailored to the needs of a specific application to meet specific size and load requirements.

Long-Term Durability: Highly wear-resistant materials and protective measures ensure long-term reliable operation in harsh environments.

Composite Load Management: Effectively deal with stress and wear caused by complex loads in multiple directions.

Space and Weight Savings: In applications that require large bearings, multiple load handling problems can be solved with a single bearing, saving space and weight.

Precise Control of Motion: Provides smooth and precise rotational motion, which is especially important for precision equipment and instruments.

Reduced Maintenance: Design considerations and sealing systems reduce maintenance requirements and overall operating costs

● SKF (Sweden)

● Schaeffler (Germany)

● Timken (USA)

● Rothe Erde (Germany)

● Kaydon (USA)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

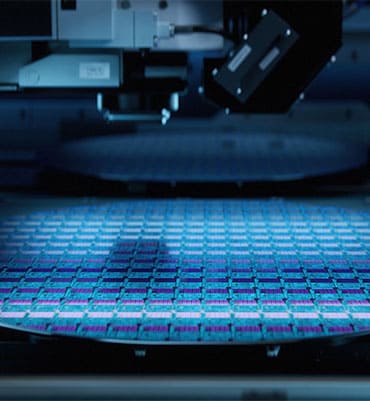

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation