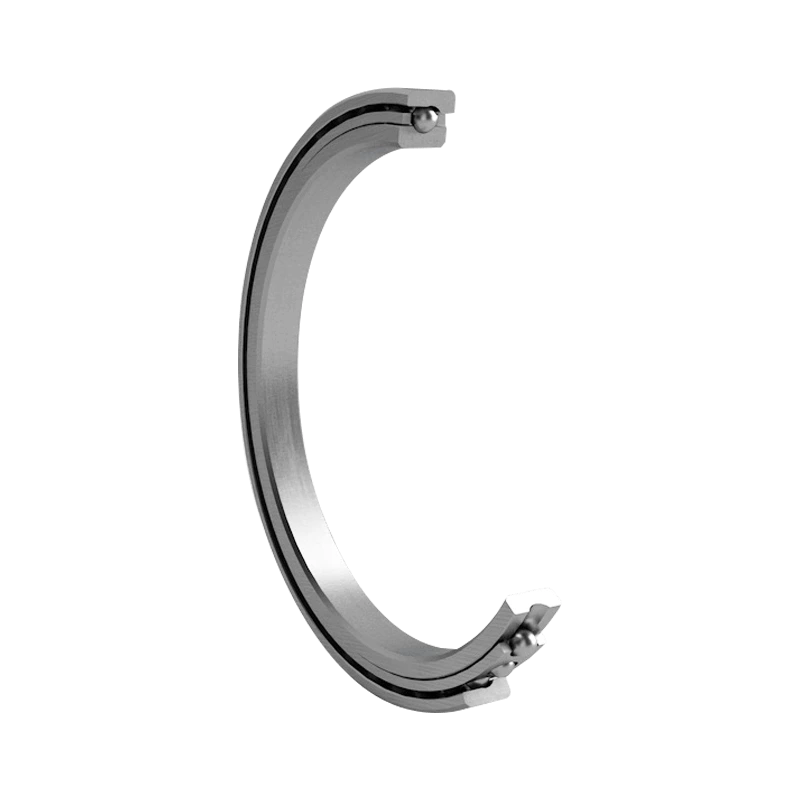

Thin section ball bearing (also known as equal cross-section bearings) are specially designed bearings characterized by a constant cross-section size over the entire range of bearing diameters. These bearings are typically used in applications where space

Thin-Walled Design: The wall thickness of the bearing with equal section is relatively thin, which makes the gap between the outer and inner diameter of the bearing very small, maintaining the lightness of the entire bearing.

Constant Cross-Section: The cross-section height of the bearing remains the same regardless of the change in diameter.

Lightweight Materials: Lightweight, high-strength materials, such as high-grade alloy steels or specific synthetic materials, are often used to reduce weight and increase load capacity.

Variety of Design Forms: Including deep groove ball bearings, four-point contact ball bearings and angular contact ball bearings, to meet different load and motion needs.

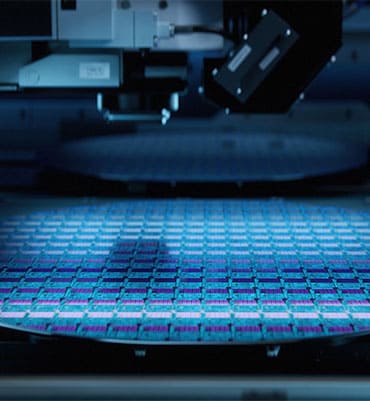

Aerospace: Used in critical components of satellites, spacecraft, and aircraft, applications that require bearings that are lightweight and space-tight.

Robotics: For robot joints and other robotic arm components that require high-precision and high-performance bearings.

Medical Equipment: Surgical robots and medical scanning equipment require small and reliable bearings.

Precision Instruments: In instruments and equipment that require high-precision control and small size bearings, such as optical instruments and precision measuring equipment.

High Performance: Despite the small cross-section, the design ensures sufficient load capacity and rigidity to meet high performance requirements.

Compact: Due to its thin-walled and equal-cross-sectional characteristics, it is suitable for compact mechanical structures.

Lightweight: The use of high-strength, lightweight materials to reduce overall weight is especially important for applications where mobility and fuel efficiency are critical.

Versatility: Accommodates different bearing design needs and can withstand radial loads, axial loads, or a combination of both.

Space Constraints: Allows bearings to be installed in very limited space without sacrificing performance.

Weight Limits: Helps reduce overall equipment weight, especially for aerospace and other fields.

Reduce Design Complexity: Simplified mechanical design and assembly processes due to its thin cross-section and light weight.

Improve Accuracy: Suitable for high-tech equipment and instruments that require high precision and reliability.

● Kaydon (USA)

● NTN (Japan)

● SKF (Sweden)

● Schaeffler (Germany)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation