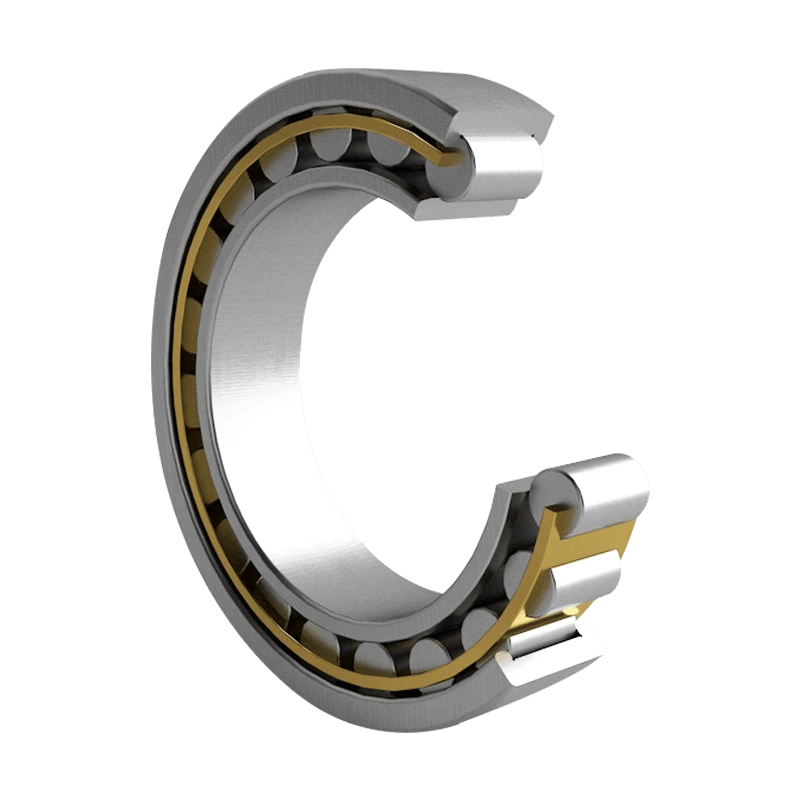

Cylindrical roller bearings are a type of bearing designed to withstand high radial loads, especially suited for working conditions that require high speeds and high precision.

Roller Shape: The rollers of cylindrical roller bearings are cylindrical, and this design allows the rollers to have a larger contact area with the raceway of the bearing, which can withstand large radial loads.

Inner and Outer rings: They have smooth inner and outer raceways in which the rollers move. The outer ring is detachable and easy to install and maintain.

Cage: The rollers are separated by a cage to maintain an even distribution and help the rollers to maintain proper guidance and avoid friction and wear.

Shoulderless Design: Some cylindrical roller bearings have a shoulderless design in the inner ring that allows the rollers to reach the bearing edge, increasing load carrying capacity.

Industrial Gearboxes: Because of the ability to withstand High-Speed rotation and heavy loads, they are widely used in various types of industrial gearboxes.

Motor: Used in high-speed motors spindle because it can effectively carry the load and reduce friction.

Machine Tool Spindles: Used in the spindles of precision machine tools where high precision and high rigidity are required.

Rail Transit: Used in train axles and transmission systems, as they must withstand heavy loads and shocks.

High-Load Bearing Capacity: Cylindrical rollers can provide a large contact area, thereby enhancing load-bearing capacity.

High-Speed Performance: Optimized design to reduces friction and heat accumulation, making it suitable for high-speed applications.

Modular Design: Many cylindrical roller bearings are designed for easy to install and maintain , allowing users to replace them faster and easier.

Durability: The structure is simple but sturdy, suitable for harsh working environments and extending service life.

Thermal Stability for High-Speed Operation: The optimized design helps the bearing to keep at a lower temperature at high speeds, improving performance and reliability.

Precise Control: In high-precision applications, such as lathe spindles, these bearings provide the required accuracy and rigidity.

Easy Maintenance: The easy-to-assemble design makes regular maintenance and inspections easier and reduces downtime.

● SKF (Sweden)

● FAG (Germany)

● NSK (Japan)

● NTN (Japan)

● Timken (USA)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

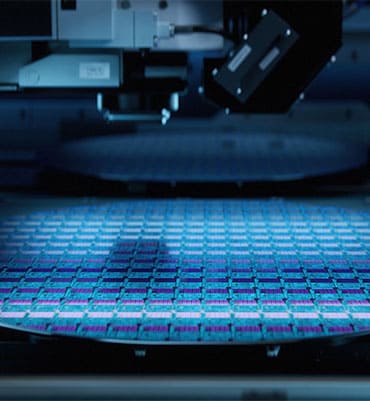

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation