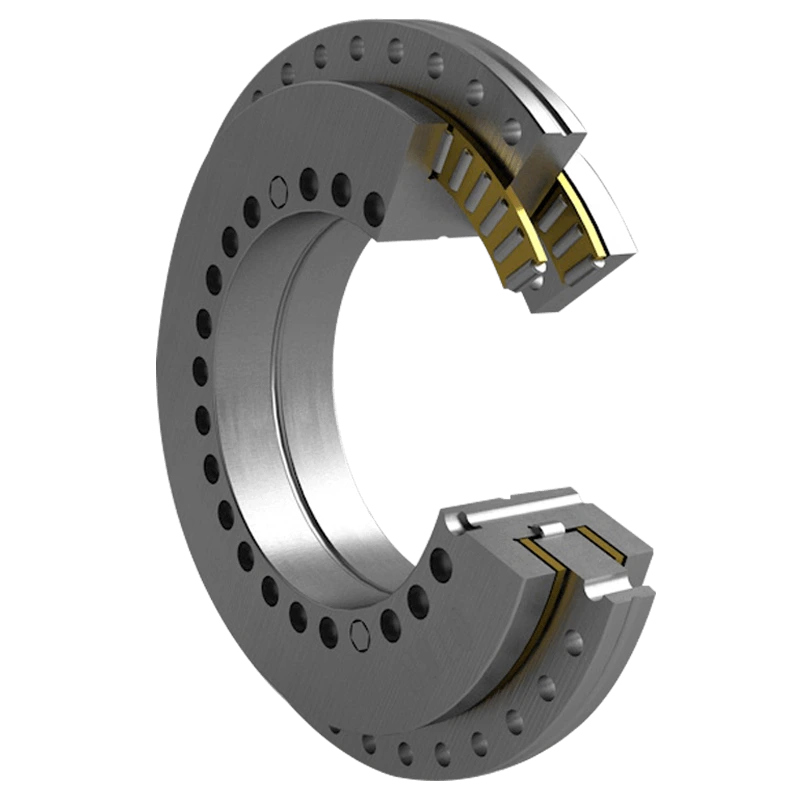

YRT bearings are high-precision, multifunctional slewing bearings. They are designed to support low-friction, precision rotation applications, and are commonly found in precision machinery, machine tools, radar and optical equipment.

YRT bearings typically consist of inner rings, outer rings, rolling elements and cages. They have the following characteristics:

High Precision: YRT bearings are usually designed for slewing bearing applications that require high precision and provide good rotational stability.

Multiple Supports: This type of bearing can simultaneously withstand axial, radial and tilting moment loads, making them suitable for complex load conditions.

Integrated Design: YRT bearings feature an integrated design that combines the inner and outer rings with a set of precision rolling elements, reducing the installation complexity and space requirements of the equipment.

Precision Rolling Element Arrangement: Specially designed rolling elements are used to reduce friction and heat generation, and enhance load capacity and stability.

YRT bearings are widely used in slewing bearing systems that require high precision and low friction. Typical application areas include:

Machine Tools: Such as CNC machine tools, grinding machines, lathes, etc., used to support the spindle and provide high precision rotation and stability.

Optical Equipment: For high-precision instruments like microscopes, projectors, etc., which require precise rotational control.

Radar Systems: used for precise rotation of antenna systems.

Rotary Platforms and Test Equipment: Specially designed rolling elements are used to reduce friction and heat generation, and enhance load capacity and stability.

The design features of YRT bearings mainly include:

Multi-point Contact Structure: The contact points between the inner and outer rings and the rolling elements of YRT bearings are evenly distributed, allowing for uniform load distribution.

High Load Capacity: Compared with conventional bearings, YRT bearings can withstand higher axial, radial and tilting moments, making them suitable for carrying complex loads.

Low Friction and High Rigidity: The optimized design reduces friction, and improves rigidity and precision.

Durability and Long Service Life: Due to its high precision and advanced design, YRT bearings have a longer service life, reducing maintenance and replacement frequency.

Improve Equipment Accuracy and Stability: In rotary applications, YRT bearings can ensure equipment accuracy, reduce deviations during motion, and improve operational stability.

Reduce Friction and Heat Generation: Optimized design can reduce friction, improve work efficiency, and the service life of the equipment.

High Load Capacity: It can withstand axial, radial and tilt loads at the same time, making it suitable for complex working conditions.

Compact Design: The integrated design saves space, reduces the number of components, and lowers system complexity.

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● IKO (Japan)

● Timken (USA)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation