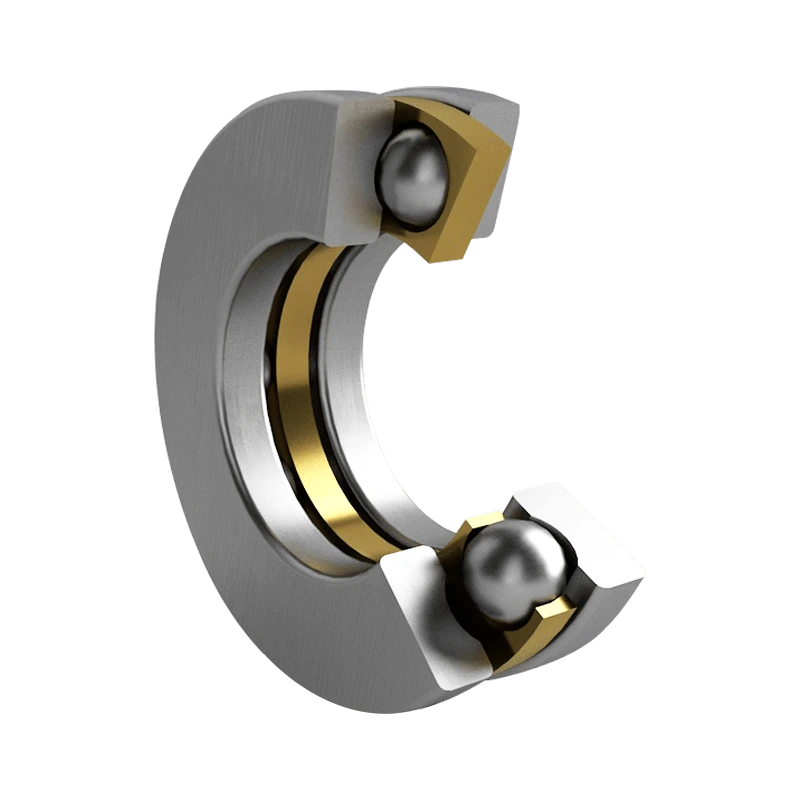

Thrust ball bearings are bearings that are designed to be subjected primarily to axial loads and are not suitable for any form of radial load. This type of bearing is commonly used between components of machinery and equipment where the components need to

Spherical Rolling Elements: Thrust ball bearings use spherical rolling elements arranged in the washed raceways of the bearings.

Two Assemblies: Consisting of a housing ring with raceways and a bearing cover ring with raceways, with the rolling elements in between.

Cage: The rolling elements are held in the correct position and spacing by the cage to ensure stable operation.

One-Way and Bidirectional: Thrust ball bearings can be divided into one-way and bidirectional, one-way bearings can only bear axial loads in one direction, while two-way bearings can withstand axial loads in both directions.

Automotive Industry: It is widely used in the clutch and other transmission systems of automobiles to withstand axial loads from transmissions.

Aeronautics: In aircraft landing gear and servos, thrust ball bearings help maintain proper movement and positioning of components when subjected to axial loads.

Industrial Machinery: In equipment such as pumps and fans, thrust ball bearings are used to support axial loads and ensure stable operation of equipment.

Household Appliances: In the rotation system of a washing machine, such as a washing machine, thrust ball bearings are used to handle the axial load generated by the basket.

High-Load Carrying Capacity: Despite their simple construction, thrust ball bearings can effectively withstand high axial loads.

Compact Design: Thrust ball bearings are typically more compact than other types of bearings, making them easy to install in space-constrained applications.

Low Friction: Optimized design to reduce friction and heat generation, increasing efficiency and durability.

Axial Displacement: Thrust ball bearings are designed to solve displacement problems caused by axial loads, ensuring proper alignment and operational efficiency of machinery and equipment.

Installation Space Constraints: Its compact design enables efficient load support even in space-constrained situations.

Improve System Reliability: Thrust ball bearings enhance the reliability and performance of the overall system by taking and controlling axial loads.

● SKF (Sweden)

● FAG (Germany)

● NSK (Japan)

● Timken (USA)

● NTN (Japan)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation