WEBINAR

Deep Groove Ball Bearing

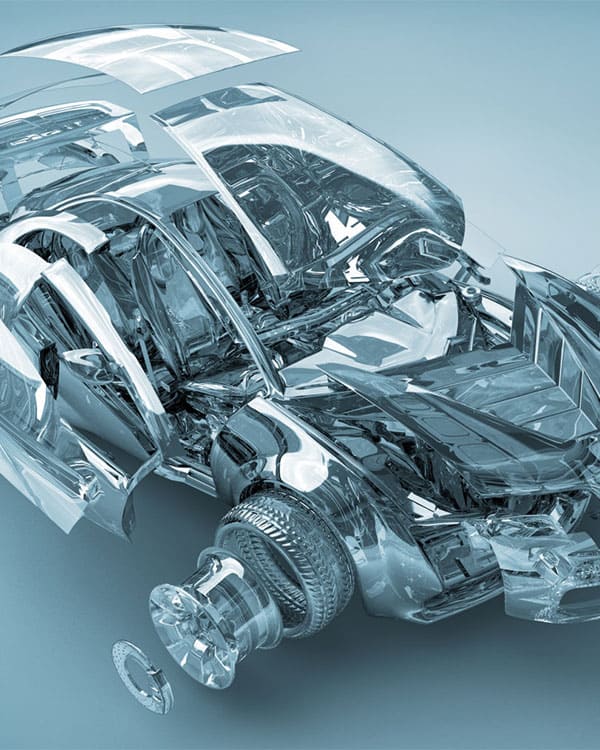

Learn MoreBearings play a vital role in the automotive industry, and their applications cover almost all key components of the vehicle, from engines to wheels, from gearboxes to steering systems. Inside the engine, bearings ensure smooth rotation of the crankshaft and camshaft, thereby increasing engine efficiency and longevity. These bearings are required to withstand extremely high temperatures and pressures, so their durability and reliability are critical to engine performance.

In the transmission system of vehicle, especially the gearbox, the role of bearings cannot be underestimated. They ensure smooth rotation of gears and reduce wear, providing smooth power delivery and enhancing fuel efficiency. Similarly, the bearings in the wheel hub directly affect the driving stability and safety of the vehicle. They not only need to carry the weight of the vehicle, but also deal with the shock and vibration caused by various road conditions.

The bearings in the steering system ensure the smooth rotation of the steering wheel, allowing the driver to control the vehicle easily and accurately. In addition, bearings in the suspension system reduce vibration and improve ride comfort while maintaining vehicle stability.

In summary, bearings are widely used in automobiles. They not only play a key role in the performance of the vehicle, but are also directly related to the stability, comfort and safety of driving. High-quality bearing design and manufacturing is an integral part of the modern automotive industry.

Automotive bearings will have to face some challenges such as the extreme temperatures, heavy loads and rotational speed conditions, so the design reliability is important and it should be able to operate for long periods of time in harsh environments without failure.

In order to improve the fuel economy and performance of automobiles, bearings must be designed with as low friction as possible . This will help to reduce energy losses and improve the overall efficiency of the vehicle.

From the engine to the gearbox, From the wheels to the steering system, bearings are essential for every parts of an automobile. This requires bearings that can be adapted to many different application scenarios and functional requirements.

As the requirements of fuel economy and performance of automotive industry are improving, bearings are also facing the demand for light-weighting to reduce overall weight of the vehicle . At the same time, the design of bearings also tends to be more compact in order to adapt to space-restricted application environments.

To meet these requirements, bearing manufacturers have to constantly exploring new materials and lubrication technologies. For instance, the use of advanced steel or ceramic materials and the development of more efficient greases and lubricants.

The automotive bearings are not only have to withstand heavy loads, but also have to cope with loads from multi-directions , such as radial loads, axial loads and instantaneous shock loads. This requires bearings with higher design accuracy and manufacturing quality.

As one of the core components of the car, bearings play a vital role. They are installed inside the car's wheel hub and their main function is to support the smooth rotation of the wheel and bear the weight of the vehicle. The design of wheel hub bearings not only needs to be able to carry heavy radial and axial loads, but also must ensure stability and efficiency during high-speed rotation.

These bearings are usually composed of precision metal rings, balls, cages and other components, designed to reduce friction during rotation, thereby reducing energy consumption and improving driving smoothness. The design of modern wheel hub bearings is becoming more and more integrated and modular, which not only makes installation and maintenance more convenient, but also helps improve overall performance and reliability. In addition, many wheel bearings also integrate ABS sensors, an innovation that allows them to play a key role in improving driving safety.

● Type of Bearing: Typically tapered roller bearings or ball bearings are used.

● Features: Able to withstand large radial and axial loads and adapt to high-speed rotation.

● Advantages: Provide stable driving and steering performance, extend service life and reduce maintenance.

The clutch bearing, also known as the clutch release bearing, is a critical component of vehicle's clutch system. This bearing is installed between the engine and the transmission, and its main function is to help smoothly disconnect or connect the power transmission between the engine and the transmission when the driver depresses the clutch pedal. This process is essential for shifting gears and temporarily stopping the vehicle's power delivery.

The design of the clutch bearing must ensure a high degree of accuracy and reliability, because it directly affects the operating feel of the clutch and the driving experience of the entire vehicle. During operation, this bearing is subjected to continuous friction and pressure, so its wear resistance and fatigue resistance are particularly important.

In order to reduce friction and improve durability, clutch bearings are usually made of high-quality materials and have optimized designs, such as special sealing technology to prevent dust and contaminants from entering the inside of the bearing. Additionally, modern clutch bearings may be equipped with special coatings or use advanced materials to reduce wear and provide a smooth operating feel.

● Type of Bearing: Thrust ball bearing.

● Features: Suitable for high-speed rotation and high-temperature environments.

● Advantages: Ensure smooth operation of the clutch.

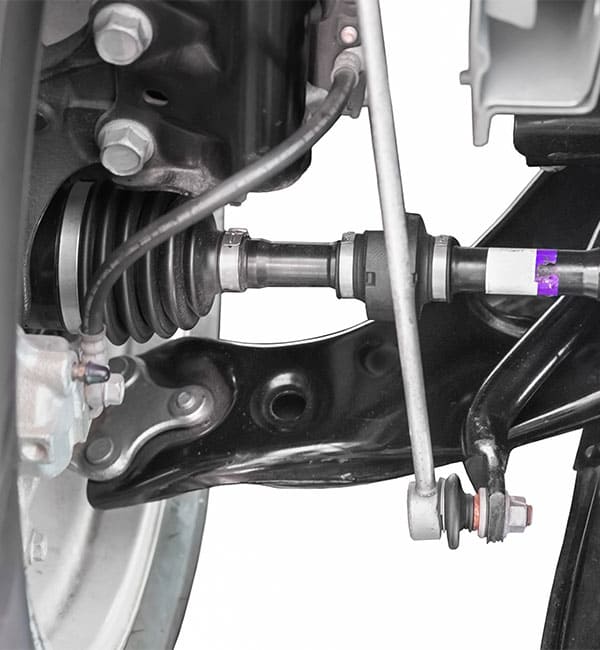

Drive shaft bearings are a key component of the vehicle's transmission system. They are mainly used to support the smooth rotation of the prop shaft and ensure that power is efficiently transmitted from the engine to the wheels. These bearings are installed on the drive shaft and bear the complex loads from vehicle operation, including radial and axial forces during high-speed rotation.

Drive shaft bearings are designed to meet demanding performance standards to accommodate a wide range of driving conditions. They must be highly durable and stable to withstand constant friction and pressure. For this reason, these bearings are typically manufactured from high-strength, wear-resistant materials and equipped with precise engineering to reduce friction, increase efficiency, and extend service life.

As the automotive industry advances, modern drive shaft bearings may also incorporate advanced technologies, such as special sealing technology and lubrication systems to reduce maintenance requirements and further improve performance. These advances not only improve bearing reliability, but also enhance the efficiency and durability of the entire drive system.

● Type of Bearing: ball bearings and tapered roller bearings.

● Features: High load-bearing capacity and impact resistance.

● Advantages: Ensure the stability and efficiency of the transmission system.

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation