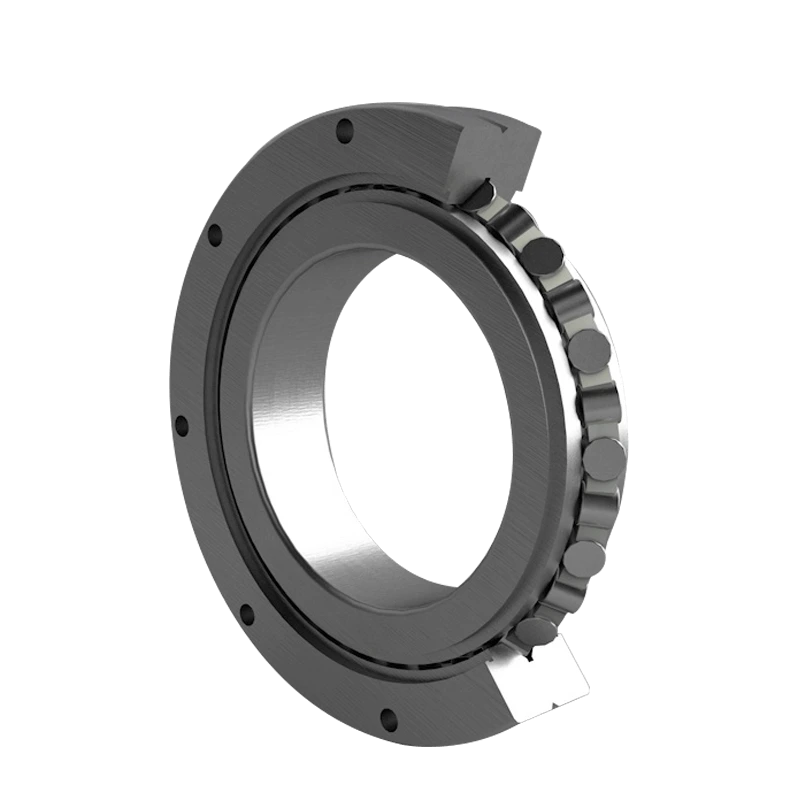

A crossed roller bearing is a specially designed bearing which the rollers are arranged in a staggered manner, providing a high degree of rigidity and precision, particularly suitable for applications with high loads and tight spaces.

Cross-Aligned Rollers: Unlike the side-by-side rollers in conventional bearings, the rollers of cross-aligned roller bearings are staggered so it can carry the loads from all directions simultaneously.

Single-Bearing Construction: The function of a combined bearing can be realized with a single bearing, saving space and reducing design complexity.

High-Precision Design: These bearings are manufactured with a very high degree of precision and can provide precise motion control.

Split Inner and Outer Rings: Some crossed roller bearings are designed to be split for easy installation and maintenance.

Robotics Industry: It is widely used in the joints and rotating parts of robots because of its high rigidity and space-saving feature.

Rotary Tables and Reference Tables: Used in precision rotary tables and machine tool reference tables because they demand high precision and high load carrying capacity.

Medical Devices: Such as the rotating parts of CT machines, which require high speed and precision.

Aerospace & Aeronautics: Used in critical components of spacecraft and aircraft, as these applications require extremely high reliability and rigidity of bearings.

High-Load Capacity: The cross-arranged rollers allow the bearings to have high radial and axial load carrying capacity in a small space.

High-Rigidity: The arrangement of the crossed rollers greatly improves the rigidity of the bearing, reducing deformation and deflection.

High-Precision: The design of this bearing reduces clearance and friction, providing high-precision rotary motion.

Compact Design: The unique design grands itself with the ability to deliver the same or even higher performance in a smaller space.

Space Constraints: Provides an effective solution for compact or space-constrained applications.

Load Requirements: Able to withstand loads in multiple directions, suitable for complex or heavy-duty applications.

Motion Accuracy: The accuracy and response speed of the motion control system are improved.

Installation and Maintenance: The detached design simplifies installation and maintenance and reduces system downtime.

● THK (Japan)

● IKO (Japan)

● INA (Germany)

● NSK (Japan)

● Timken (USA)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

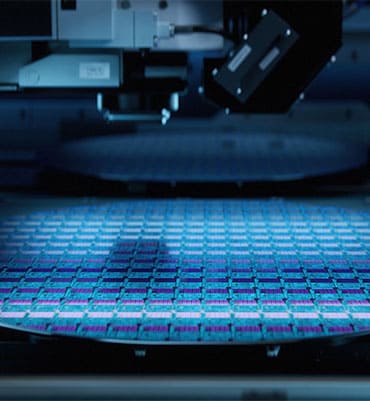

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation