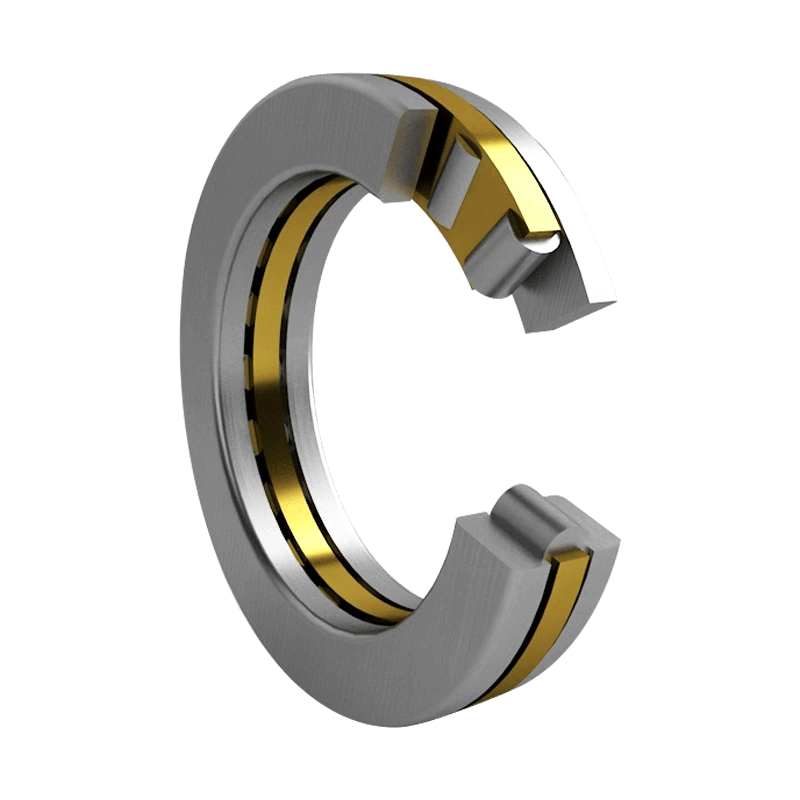

Thrust roller bearings are a type of bearing specifically designed to accommodate axial loads and are commonly used in applications with high loads. This type of bearing is known for its ability to efficiently handle large amounts of axial pressure.

Thrust Cage: Thrust roller bearings typically contain a thrust cage that is used to accommodate the rollers and keep them evenly distributed.

Roller Elements: Rollers can be cylindrical, spherical, or needle-shaped, depending on the design and application needs.

Wash Design: Consists of two washers (axial rings), one fixed on the shaft and another one fixed on the housing, and the rollers run between the two washers.

High-Load Bearing Design: These bearings are designed to withstand high axial loads, typically with little or no radial loads.

Industrial Machinery: Common in machine tool spindles, automotive clutches, pumps, and compressors to handle axial forces in High-Speed rotation.

Automotive: Used in automotive drivetrains, especially in components such as gearboxes and drive shafts, to withstand the thrust generated when shifting.

Heavy Machinery: In construction and mining equipment, such as the rotating platforms of excavators and the main bearings of cranes, they are subject to large axial loads.

Aviation: In aero engines and turbines, thrust roller bearings are used to handle axial loads caused by high-speed rotation.

High-performance Load Carrying Capacity: Thrust roller bearings are designed to maximize axial load carrying capacity while minimizing space usage.

High-Speed Adaptability: Designed to handle High-Speed applications to ensure stability and reliability at high speeds.

Wear-Resistant Materials: Manufactured using high-strength steel or other alloying materials to improve wear resistance and longevity.

Versatile: Available in different forms and sizes to suit the specific needs of a variety of industrial applications.

Axial Displacement Problem: Effectively control the axial displacement in mechanical equipment to ensure the accuracy of equipment operation.

High-Load Condition: Reliable support for machinery and equipment under heavy load conditions, reducing maintenance frequency and costs.

Ease of Assembly and Maintenance: Designed with ease of assembly in mind to reduce the complexity of installation and maintenance work.

Environmental Adaptability: Ability to work in a variety of environments, including high temperatures, high pressures, or other harsh conditions.

● SKF (Sweden)

● Timken (USA)

● NSK (Japan)

● FAG (Germany)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

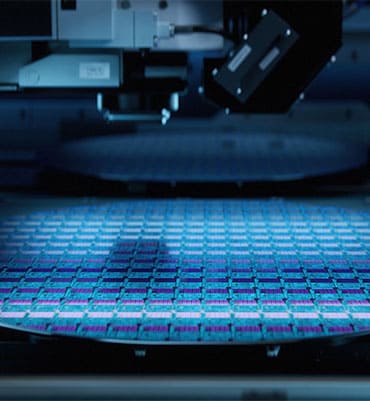

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation