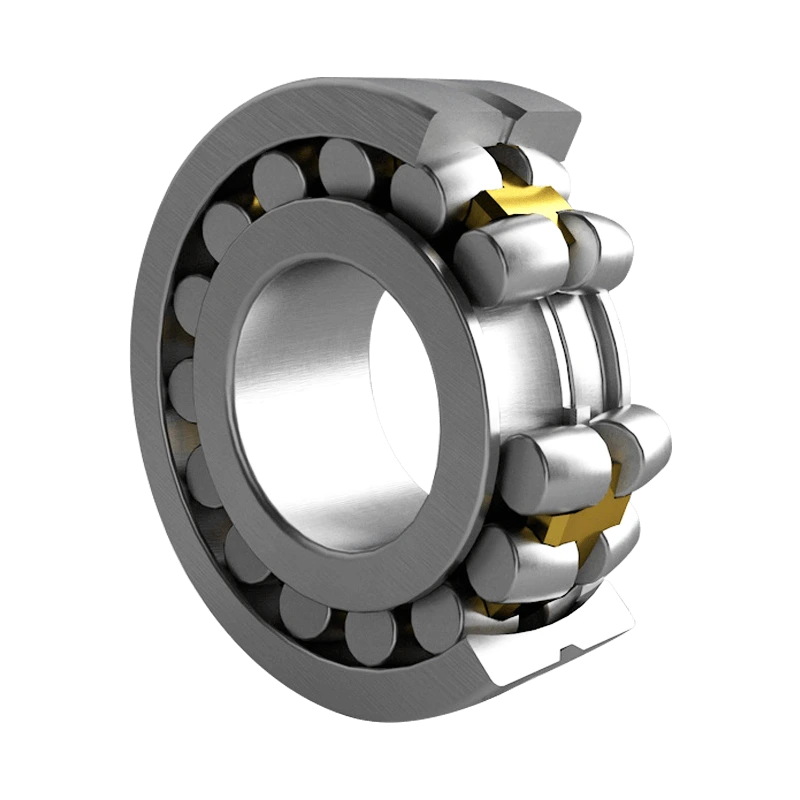

Spherical roller bearings are specially designed bearings that are capable of withstanding both high radial and axial loads, while having the ability to adjust for incomplete alignment. These bearings are ideal for use in complex load conditions and appli

Two Rows of Rollers: Spherical roller bearings are usually equipped with two symmetrically arranged rollers, which increases the load capacity of the bearing.

Spherical Raceways: The outer ring raceways are spherical, which gives the bearing self-aligning ability to work properly when there is a deviation in the installation or when the shaft is bent.

Barrel Rollers: The rollers are barrel designs that provide a larger contact area, enhanced load capacity and reduced edge stress.

Inner Ring Design: The inner ring usually has two raceways that correspond to two rows of rollers.

Heavy Industry: Applications such as rolling mills in steel mills, crushers and cement mills in the mining industry often require bearings to withstand high loads and possible shaft deflection.

Wind Power: Spherical roller bearings are used in the gearboxes and generators of wind turbines, which are often subject to variable loads and misalignment.

Paper Machinery: Used in the drying drum of a paper machine, it needs to handle heavy loads and high temperatures.

Marine Applications: For example, in the propulsion system of ships, bearings must withstand heavy loads and corrosion in saltwater environments.

Self-Aligning Capability: It can compensate for installation errors or bending of the shaft, reducing the accuracy required for installation.

High-Load Capacity: Barrel rollers and dual raceway design enhance the radial and axial load capacity of the bearings.

Durability & Reliability: Designed for long periods of operation in demanding environments, reducing maintenance frequency and costs.

Wide Range of Sealing and Lubrication Options: Different sealing and lubrication systems are available to suit a variety of operating environments.

Alignment Error: Solve shaft deflection problems caused by installation errors or during operation, reducing maintenance needs and improving efficiency.

Withstand Heavy Loads: Capable of handling high radial and axial loads, making it suitable for a wide range of heavy-duty applications.

Adaptable to Complex Environments: Designed to withstand adverse conditions such as high temperatures, pollution, and humidity.

Extend The Life of Your Equipment: Extend the life of your entire machinery by reducing wear and tear on your shafts and parts.

● SKF (Sweden)

● FAG (Germany)

● NSK (Japan)

● Timken (USA)

● NTN (Japan)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

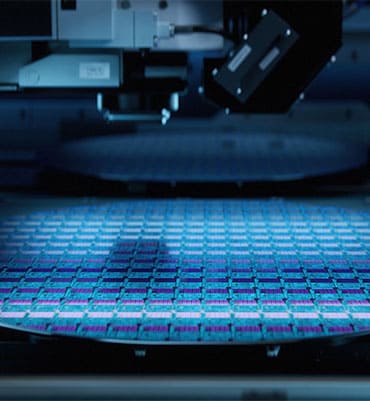

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation