WEBINAR

Deep Groove Ball Bearing

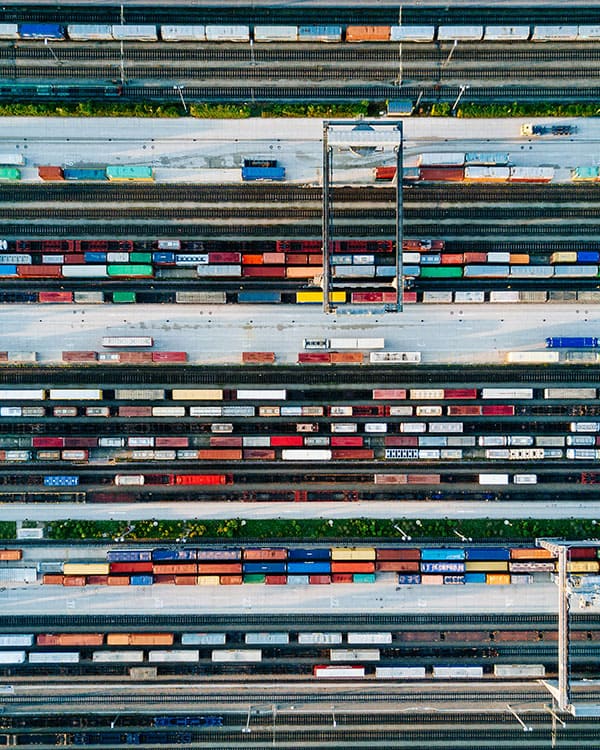

Learn MoreIn the railroad industry, the role of bearings cannot be underestimated. They are widely used in key components of railroad vehicles such as wheels, axle-boxes, bogies, traction motors and braking systems. Bearings in these components ensure the movements smoothly and efficiently , which can reduce friction, abrasion, and extend the service life of the vehicle. The reliability of bearings is particularly important in high-speed trains and heavy freight transportation, where any failure could lead to serious safety issues.

High-quality bearings provide the high precision and rigidity which required for railroad vehicles, keeping them stable at high speeds and reducing vibration and noise. In addition, optimized bearing designs help improve energy efficiency and reduce energy consumption, which is important for environmental protection and sustainable transportation.

Bearings in railroad systems must also be adapted to extreme operating conditions such as temperature variations, severe weather and long operating hours. As a result, they are often manufactured from durable materials and equipped with efficient sealing and lubrication systems to withstand these challenges.

In conclusion, bearings for the railroad industry is crucial, they are not only ensure the stability and safety of railroad transportation, but also enhance the overall operational efficiency and reliability. In the railroad industry which continues to pursue higher speed and greater capacity in today, the innovation and optimization of the bearing technology is important for the development of the industry.

Railway bearings are required to withstand extremely high loads, including the weight of heavy trains and the additional forces generated when operating at high speeds. This requires bearings with excellent load-bearing capacity and structural stability.

Considering the maintenance costs and complexities of railway systems, bearings are designed to require minimal maintenance while having a long service life to reduce train outages and repair time.

Railway bearings are often exposed to harsh environments, including moisture, salt spray, dust and chemicals. Therefore, bearing materials and surface treatment technologies must have good corrosion resistance to protect the bearings from damage.

With the development of high-speed railways, bearings need to maintain high-performance operation under high-speed rotation conditions, which includes low friction, high precision and good thermal stability.

In order to maintain the performance of the bearings during long-term operation, railway bearings are equipped with efficient sealing systems to prevent the entry of contaminants and ensure that the effectiveness of the lubricant is not affected.

Railway bearings will experience shock and vibration caused by track unevenness, wheel-rail contact, etc. during operation. Bearings need to be designed to absorb these shocks and vibrations and maintain stable operation.

The operational stability and safety of railroad vehicles are largely depend on the performance of the wheels and axle-boxes, and the most important parts of these components are the bearings. The function of bearings in wheels and axle boxes is to support weight, reduce friction and transmit forces to ensure smooth and efficient operation. In these applications, bearings are designed to withstand significant loads and are also required to cope with the vibrations and shocks that occur during railroad travel.

Railroad wheel and axlebox bearings are typically designed to be high-strength and wear-resistant to withstand long-term repetitive stresses and dealing with harsh environmental conditions. These bearings must have a high degree of reliability and durability, as any bearing failure can lead to serious safety hazards. In addition, the high-performance design of these bearings is critical to reducing energy consumption and minimizing maintenance costs.

● Type of Bearing: Tapered roller bearings, cylindrical roller bearings.

● Features: Able to withstand heavy load and shocks,anti-wear resistance.

● Advantages: Ensures the motion of wheels smoothly, reduces friction and improves energy efficiency.

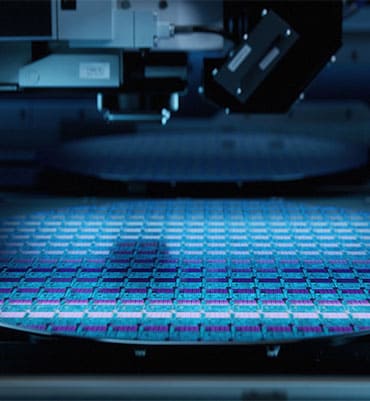

Railroad traction motors are the core of the power system of a railroad vehicle, which keep the train moving forward. The role of bearings in this critical system is to support the motor shaft and ensure its smooth and accurate rotation at high speeds. Bearings in railroad traction motors need to have high speed capability and low friction to increase motor efficiency and reduce energy loss.

Since railroad traction motors generate a lot of heat during operation, the bearings need to have good heat resistance and be able to work stably under high load and high speed conditions for long periods of time. These bearings also need to have a high degree of reliability and durability, as any failure could lead to train stoppages, affecting the efficiency and safety of rail transportation.

In addition, the bearings of railroad traction motors need to adapt to the specific environment of railroad transportation, such as vibration, dust and temperature fluctuations. Therefore, they are usually made of high-strength materials and equipped with effective sealing and lubrication systems to ensure stable operation under harsh conditions in long term.

● Type of Bearing: Deep groove ball bearings, cylindrical roller bearings.

● Features: Adapted to high speed operation, low friction and low noise.

● Advantages: Improve motor efficiency and reduce maintenance requirements.

The bogie is the key part of a railroad vehicle, which for supporting the carriages, transmitting and cushioning loads, and allowing the vehicle to steer smoothly on the track. The function of the bearings in this critical area is to ensure smooth relative motion between the wheel-set and the vehicle body, while supporting dynamic loads from the weight of the vehicle and during operation. High-performance bearings are essential for the stability and flexibility of the bogie, which allowing the train to turn smoothly, reducing track wear and improving ride comfort.

Bearings in railroad bogies must have extremely high load carrying capacity and wear resistance, as they experience continuous stress and shock during train operation. These bearings also need to be adapted to a wide range of operating conditions, including high speeds, long distances and variable climatic conditions. As a result, they are often made of high-strength materials and equipped with efficient sealing and lubrication systems to ensure stable operation and long-term durability in harsh environments.

● Type of Bearing: Ball bearing, needle roller bearing.

● Features: Withstand multi-directional loads, flexible and reliable.

● Advantages: Ensure the vehicle steering is flexible and improve driving safety.

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation