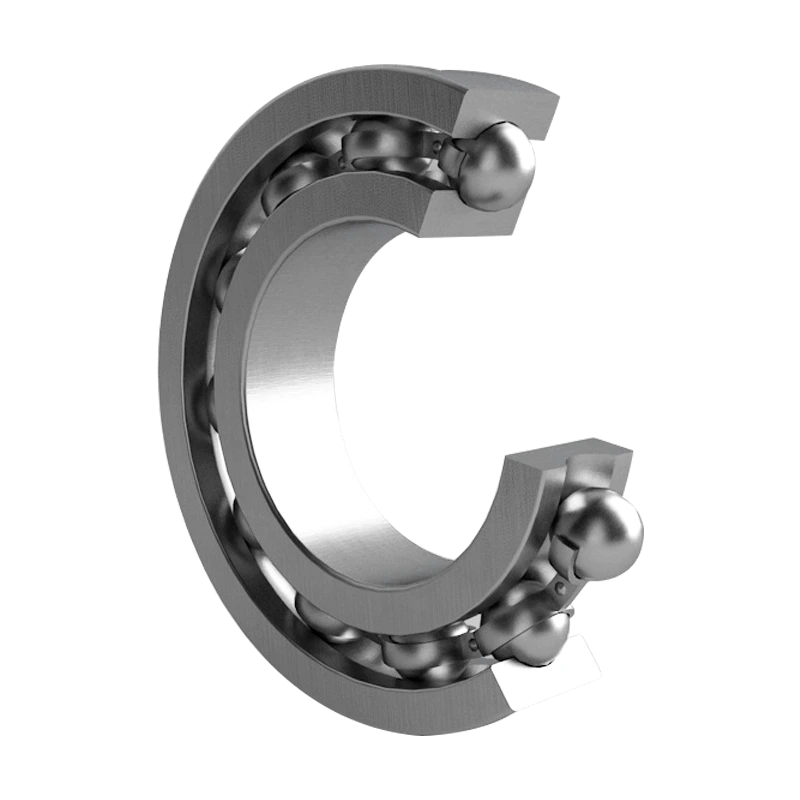

Deep groove ball bearings are a common type of bearing that is widely used in a variety of mechanical equipment.

Single and double row designs: Deep groove ball bearings can be single or double rows. The single-row design is suitable for standard loads, while the double-row design is suitable for higher loads.

Track depth: The inner and outer rings of the bearing have a deeper track, which increases its radial load capacity.

Ball spacing: The steel balls in the bearing are separated by a cage, which ensures that the steel balls are evenly distributed and improves the stability and efficiency of the bearing.

Sealing and shielding: Depending on the application, bearings can be configured with different types of sealing or shielding caps, such as rubber seals and metal shields.

High-speed applications: High-speed rotating parts in electric motors, household appliances, and power tools.

High-load applications: Drive systems in industrial machinery and the automotive industry.

Precision instruments: Used in instruments that require high precision and low noise.

Outdoor equipment: Used in agricultural machinery and construction equipment, which are often exposed to harsher environments.

High load-bearing capacity: The deep track design allows the bearings to withstand high radial and axial loads.

Durability: High-quality steel and precision manufacturing ensures that the bearings can operate for a long time in harsh environments.

Self-lubricating design: Some types of deep groove ball bearings are equipped with self-lubrication to reduce the need for maintenance.

Diverse sealing options: A variety of sealing designs are available to cater different working environments and dust-proof and waterproof needs.

Reduce maintenance costs: Reduce the frequency of maintenance and replacement of the equipment by providing high-quality and long-life bearing solutions.

Efficiency improvement: Ingenious design improves the efficiency of mechanical components and reduces energy consumption.

Adapt to harsh environments: Special seals and material selections allow bearings to operate in extreme or corrosive environments.

Reduce of noise and vibration: Sophisticated engineering design helps reduce noise and vibration during operation and improve user experience.

● SKF (Sweden)

● NSK (Japan)

● FAG (Germany)

● NTN (Japan)

● Timken (USA)

Bearings are widely used in automobile engines, transmission systems, wheels and other critical components to support rotational motion and reduce friction.

In the energy industry, such as wind power, solar power and traditional power plants, bearings are used to support turbines, fans, generators and other equipment.

The field of heavy machinery manufacturing such as excavators, loaders, excavators, etc. Using bearings to support and rotate various moving parts.

Bearings are used in train and subway systems to support wheels and other moving components.

In marine and marine engineering, bearings are used to support ship engines, propellers, transmission systems, etc.

Bearings play a vital role in the design and operation of robotic arms. They not only ensure the smooth and precise movement of the robotic arm, but also have a direct impact on improving the performance, reliability and efficiency of the robotic arm.

Bearings are also often used in electronic equipment, such as computer hard drives, printers, and optical drives.

In medical equipment, such as scanners, X-ray machines, and surgical equipment, bearings are also be required.

The aerospace sector uses bearings to provide support in equipment such as aircraft landing gear, wing controls and satellite panels.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation