WEBINAR

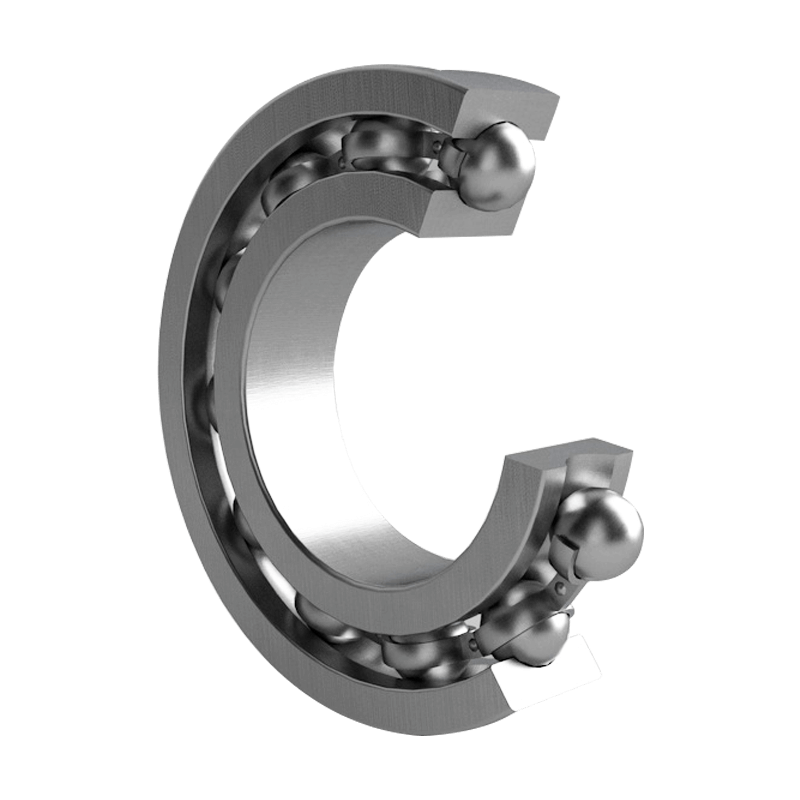

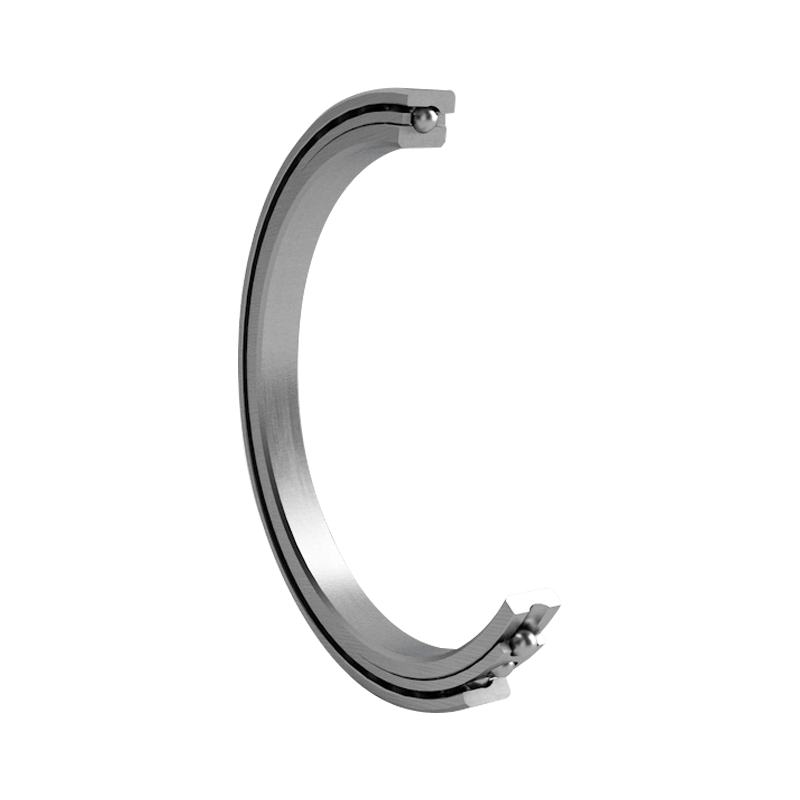

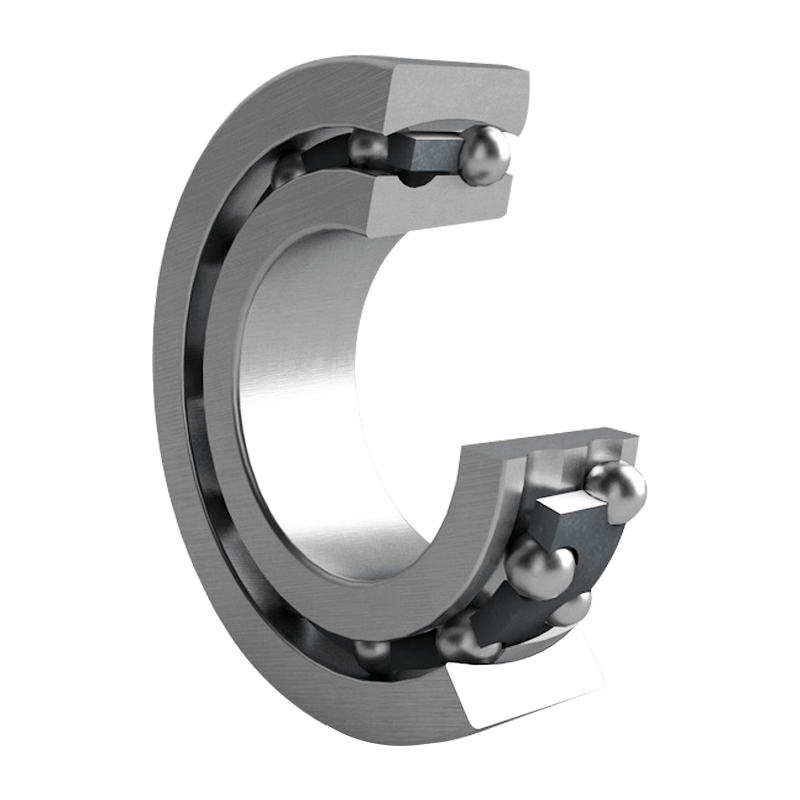

Deep Groove Ball Bearing

Learn More

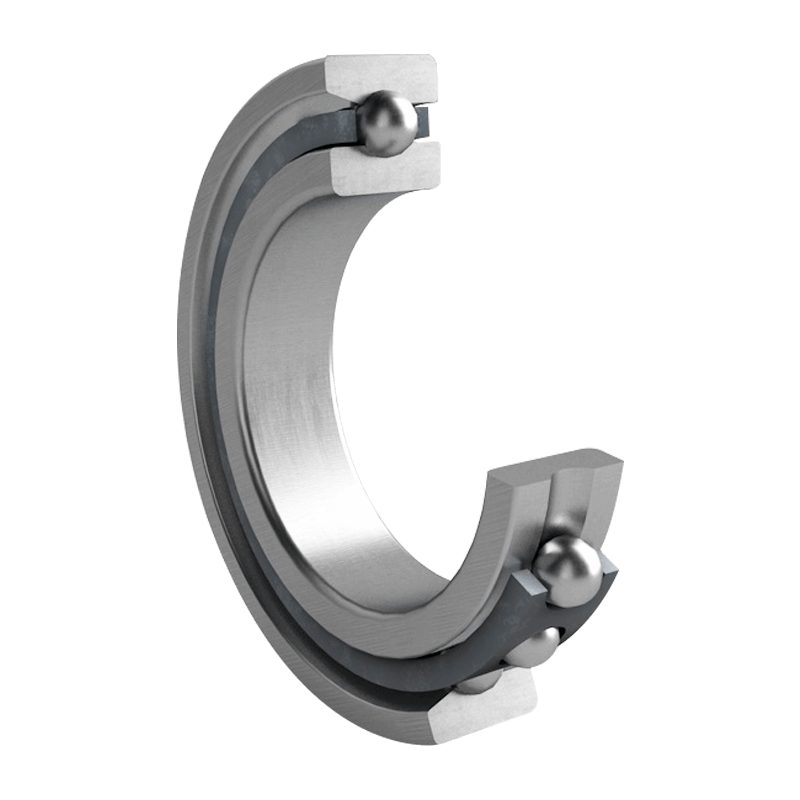

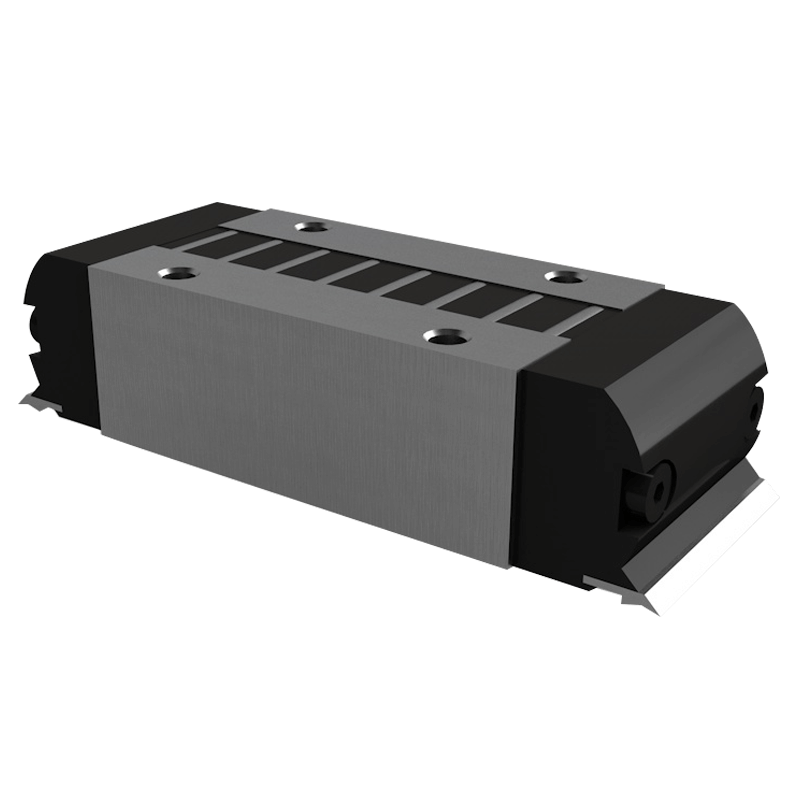

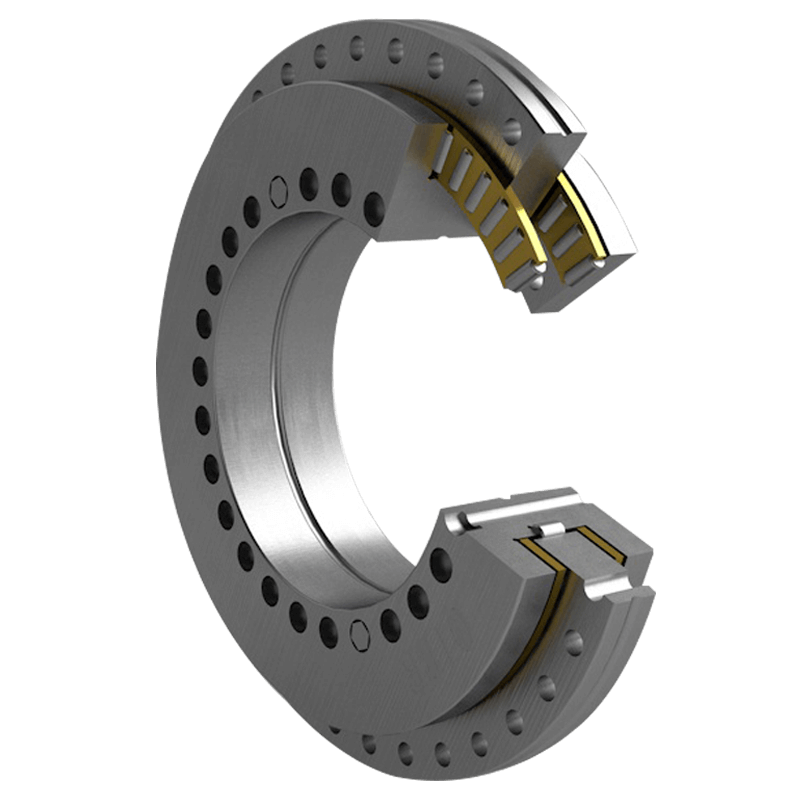

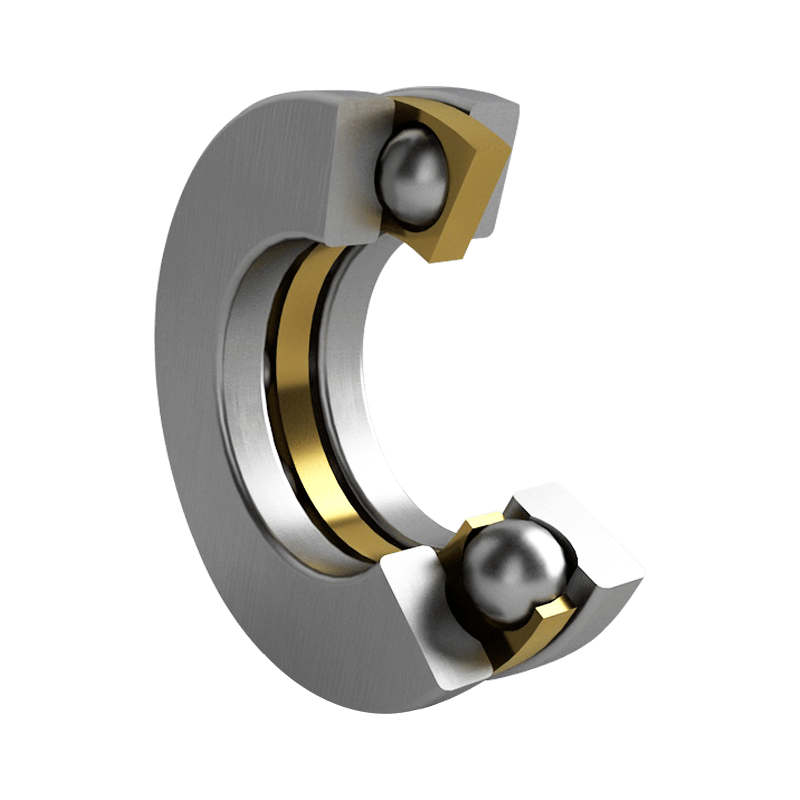

Disassemble the angular contact ball bearings requires caution and uses appropriate tools. Here are the general methods and tools required for disassembling angular contact ball bearings:

Clean the Work Area: Before starting disassembly, make sure the work area is clean and has appropriate personal protective equipment, such as gloves and eye protection, ready.

Lubrication: If the bearing is used in operation, please properly lubricate the bearing first to reduce friction during disassembly.

Locking Devices: If the bearing housing has locking devices (such as screws or pins), please loosen them first so the bearing can move freely.

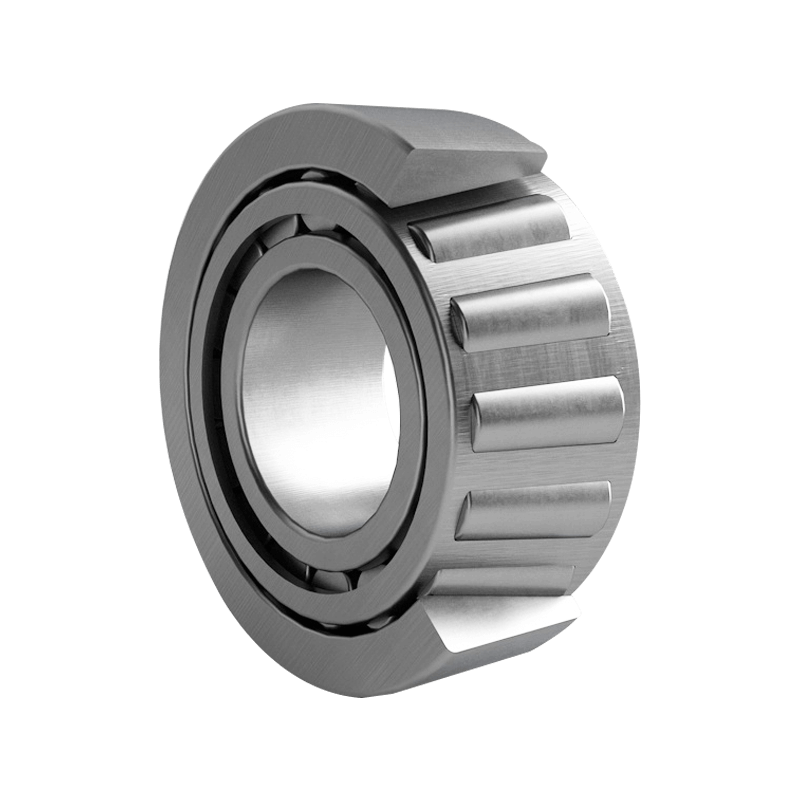

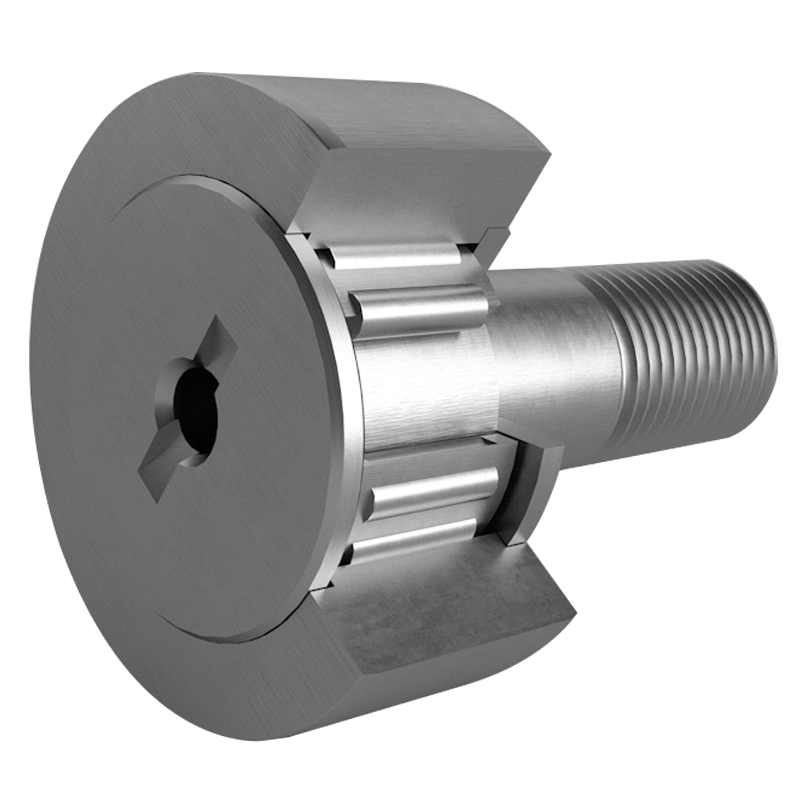

Use Bearing Removal Tools: Use specially designed bearing removal tools, which often include bearing separators and bearing pullers. These tools help remove the bearing without damaging its internal components.

Bearing Pulling: Properly install the bearing puller onto the bearing, making sure to apply even force to avoid bearing deformation. Depending on the bearing size and type, different types of pullers may be required.

Apply Force: Use appropriate tools and force to gradually apply disassembly force to remove the bearing from the shaft or race. Avoid using excessive force and prevent damage to bearings or shafts.

Inspection: Once the bearing has been successfully disassembled, carefully inspect the bearing and related components to make sure they are not damaged or worn.

Bearing Removal Tools: Including tools such as bearing separators, bearing pullers, and bearing removal hammers.

Hand Tools: Appropriately sized spanners, wrenches, box wrenches and screwdrivers for loosening locking devices and associated bolts.

Lubricant: Use the appropriate type of lubricant to reduce friction during disassembly.

Personal Protective Equipment: Including gloves, safety glasses and earplugs for safety and protection.

Bearing Inspection Tools: After disassembly, tools may be needed to inspect the bearings for wear and damage.

Please note that removal of bearings requires care and may require specialized skills and experience. If you are not sure how to disassemble the bearing correctly, please seek professional mechanical maintenance or technical support.

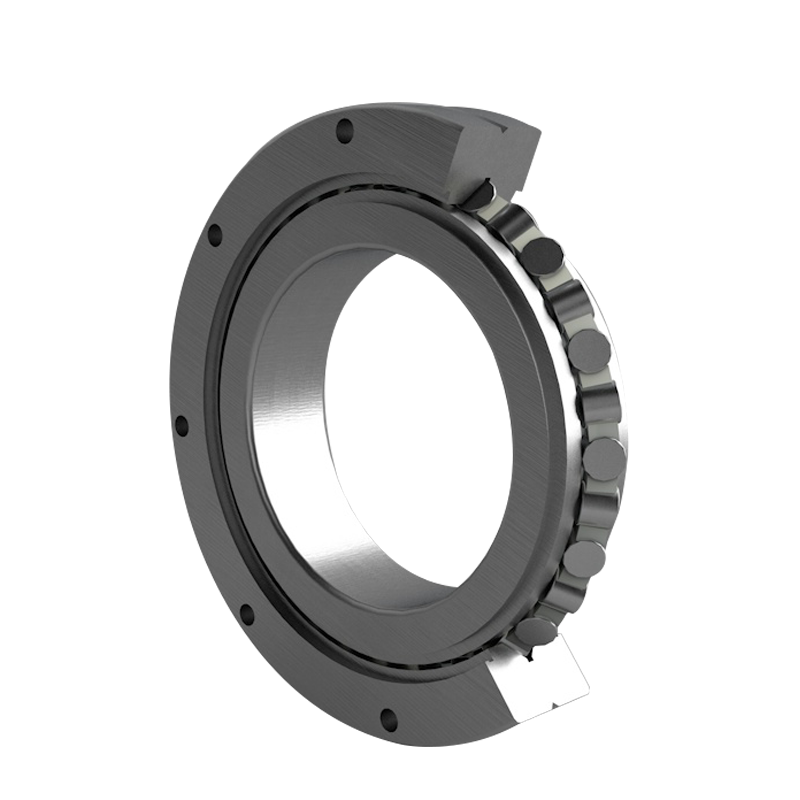

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation