WEBINAR

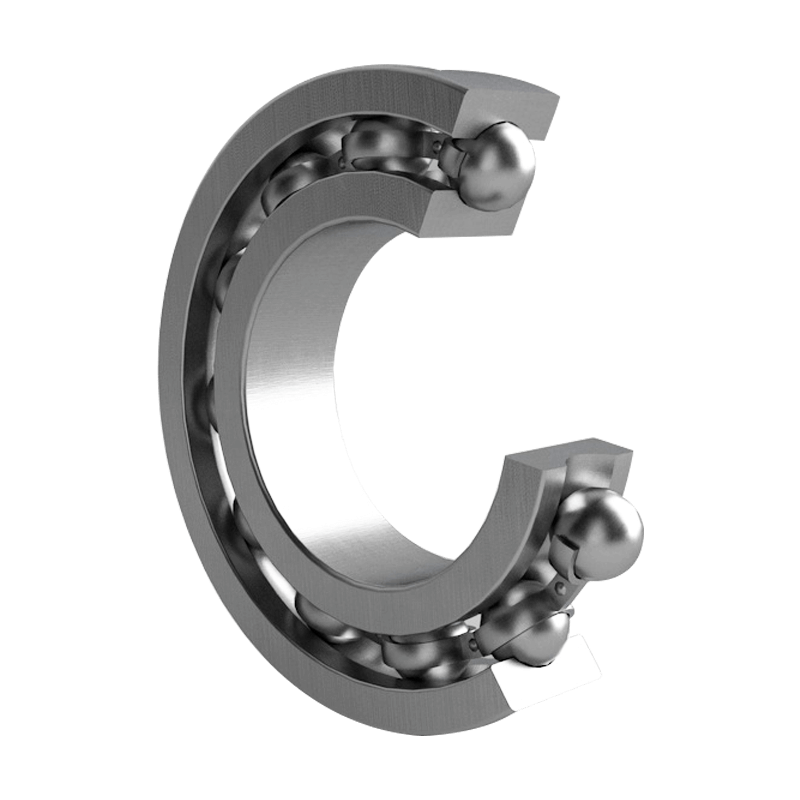

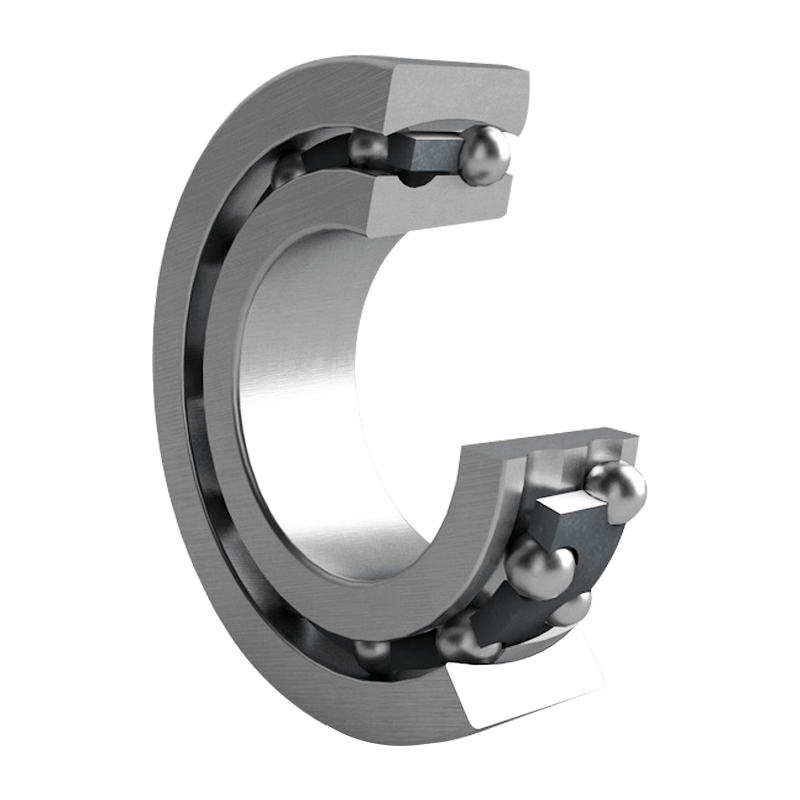

Deep Groove Ball Bearing

Learn More

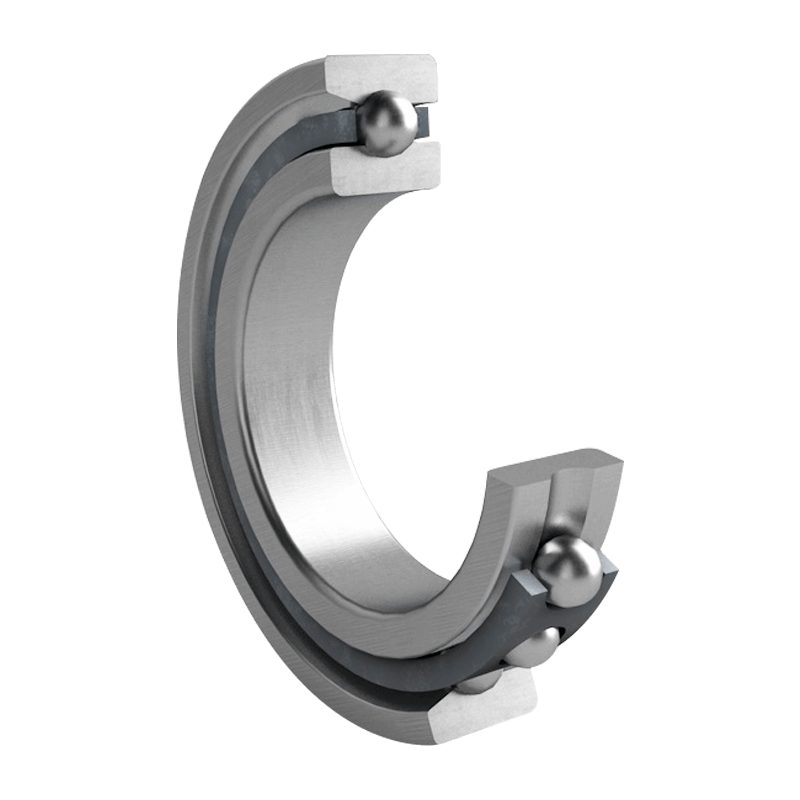

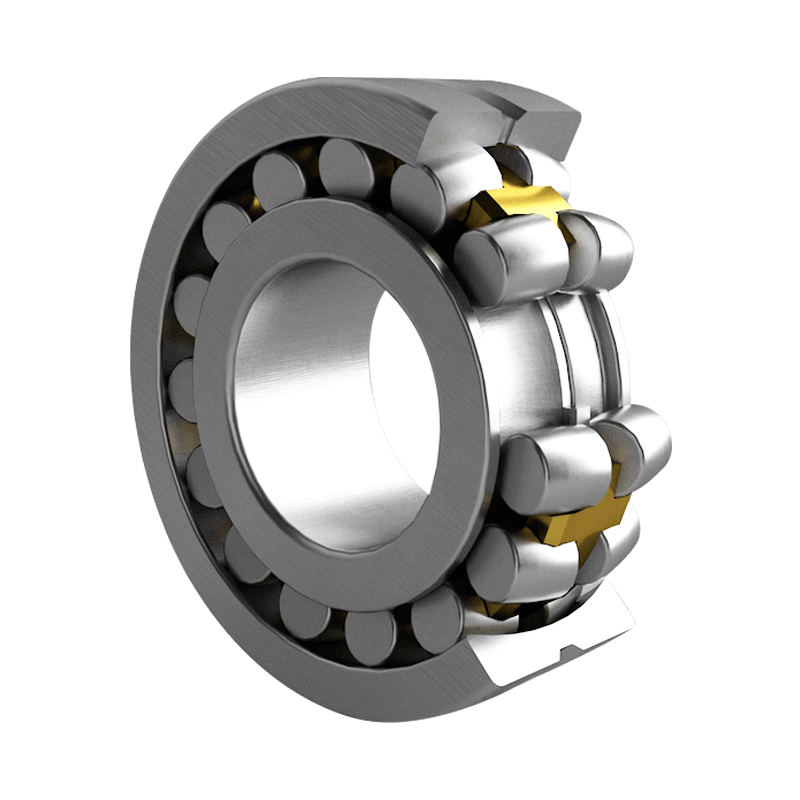

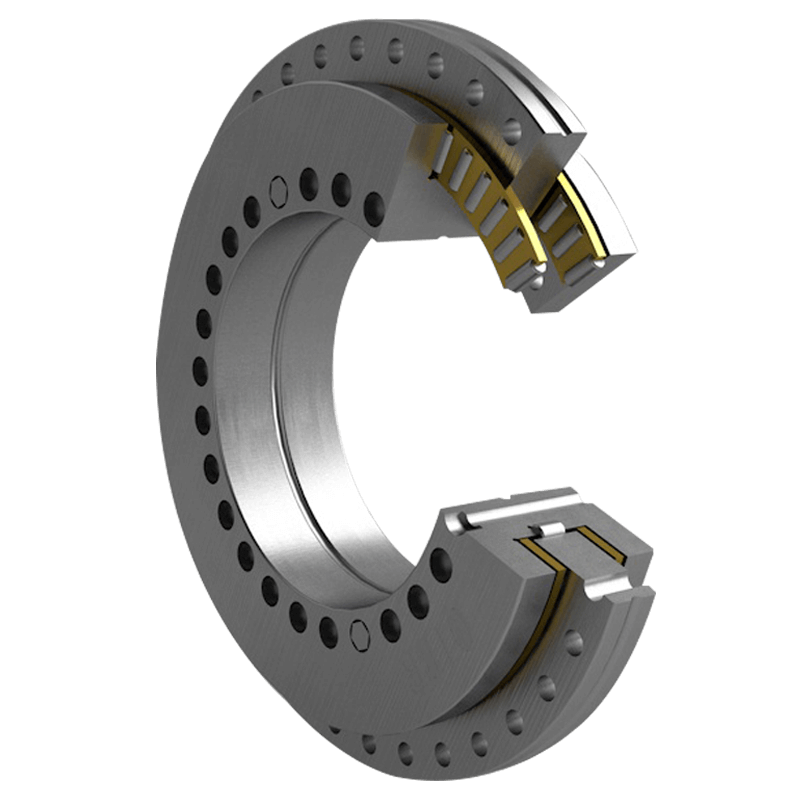

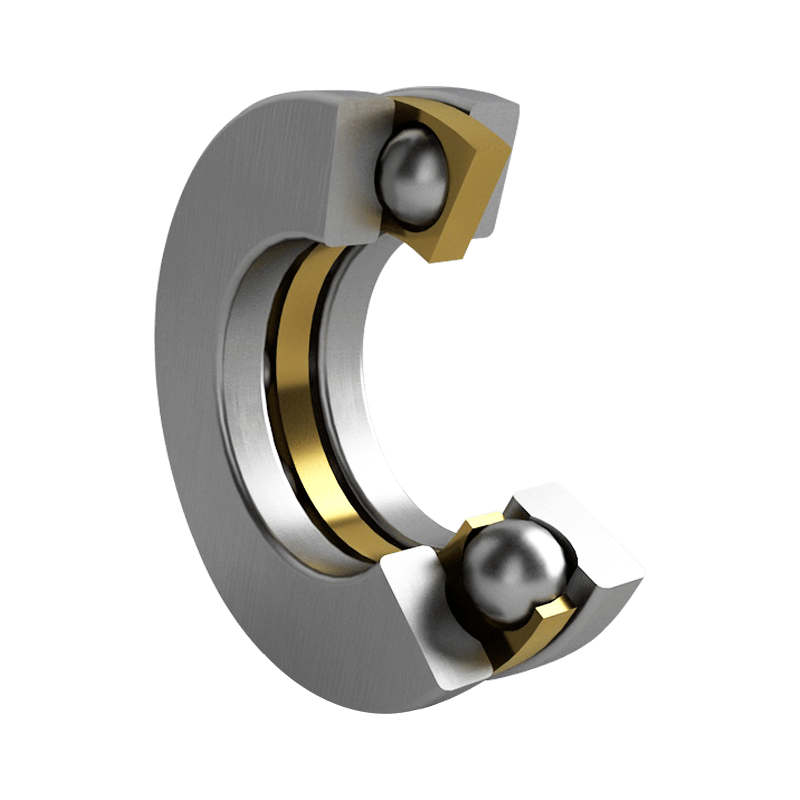

Angular contact ball bearings have many advantages in high-speed applications, but there are also some performance and limitations considerations:

High Speed Capability: The angular contact ball bearing design makes it suitable for high speed rotational applications. They have low friction and inertia, providing good performance at high speeds.

Accuracy: Angular contact ball bearings generally have high accuracy and are suitable for applications that require high precision and positioning accuracy, such as machine tools and precision instruments.

Rigidity: Due to their design, angular contact ball bearings have high rigidity and are able to withstand large axial and radial loads, making them suitable for applications requiring high load capacities.

Axial Load Capacity: Angular contact ball bearings are capable of handling high axial loads in high-speed applications, which is important for some applications.

Lubrication Requirements: lubrication is critical in high speed applications. Improper lubrication can cause friction and wear, reducing bearing life. Therefore, lubrication requirements must be strictly followed and maintained regularly.

Temperature Control: At high speeds, friction generates heat, so an effective temperature control system is required to prevent bearings from overheating. High-speed applications often require cooling systems or temperature monitoring.

Vibration and Noise: High-speed operation may cause vibration and noise problems. So it is necessary to mitigate vibration and noise to improve the comfort and stability of the working environment.

Installation and Maintenance: The requirements of the installation and maintenance of angular contact ball bearings are very strict and require specialized knowledge and equipment. Improper installation and maintenance may cause performance degradation or failure.

Cost: Angular contact ball bearings are generally more expensive than other types of bearings, such as deep groove ball bearings, and there is a cost factor to consider.

Overall, angular contact ball bearings perform well in high-speed applications, but require special attention to issues such as lubrication, temperature control, and vibration and noise. Correct bearing selection and proper maintenance are critical to ensuring performance and reliability in high-speed applications.

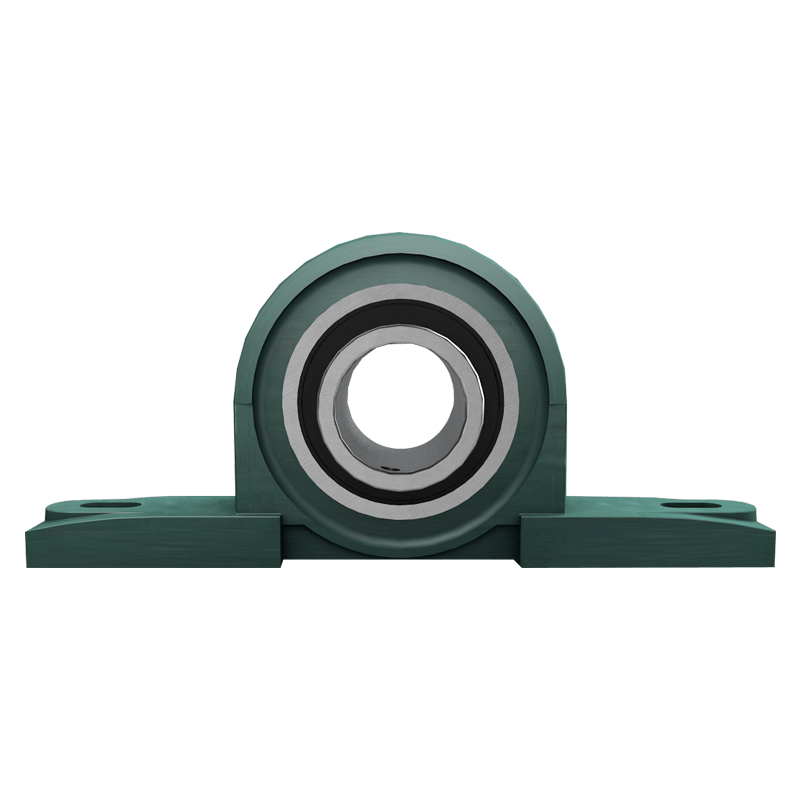

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation