WEBINAR

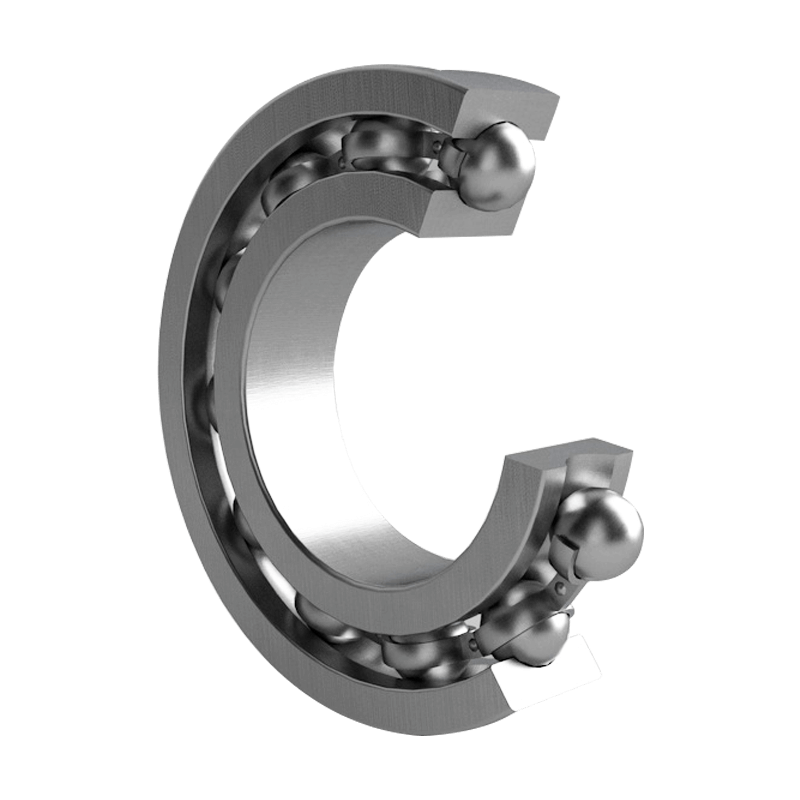

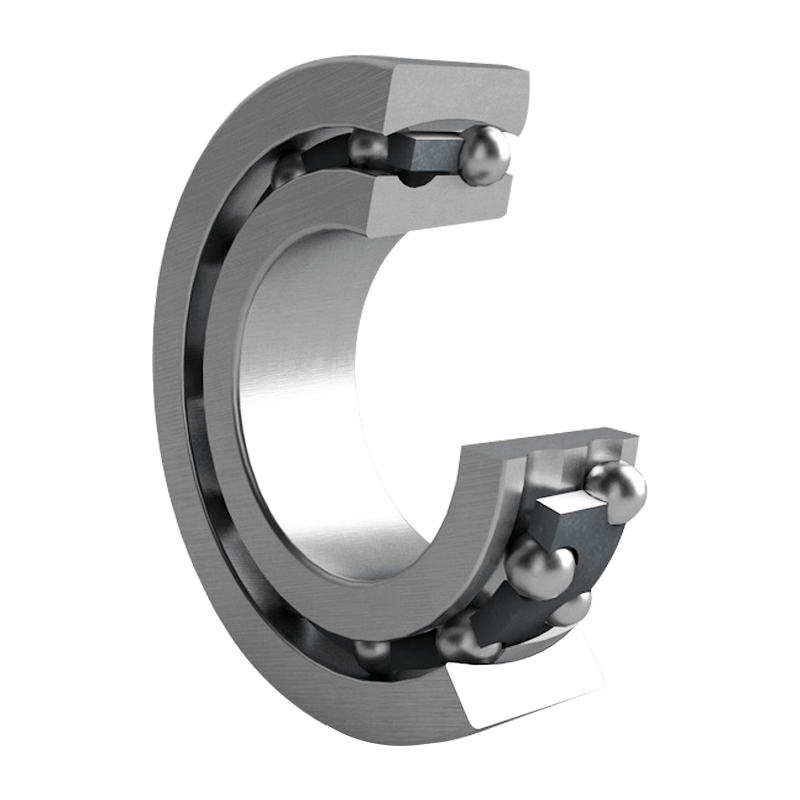

Deep Groove Ball Bearing

Learn More

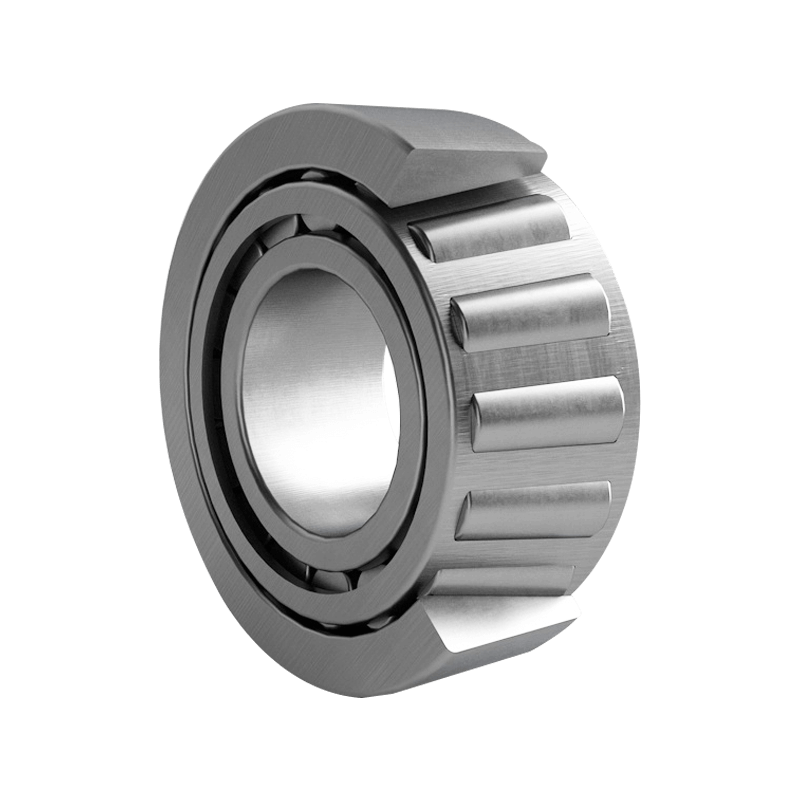

The application of needle roller bearings in wind turbines is very important. They bear the huge load of the rotating parts of the wind turbine and ensure the reliability and performance of the wind turbine.

Here are some key applications of needle roller bearings in wind turbines:

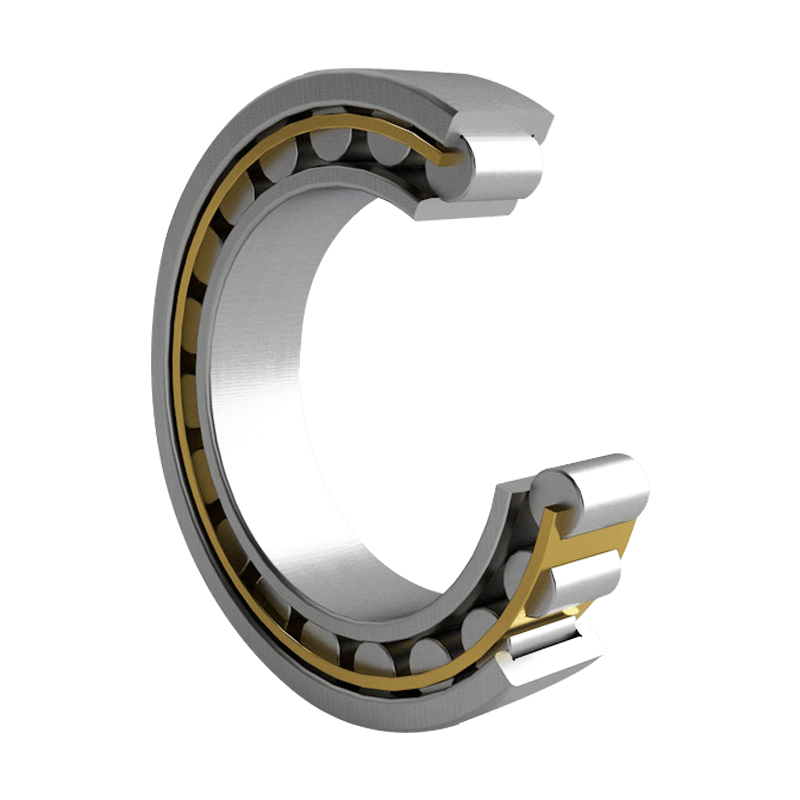

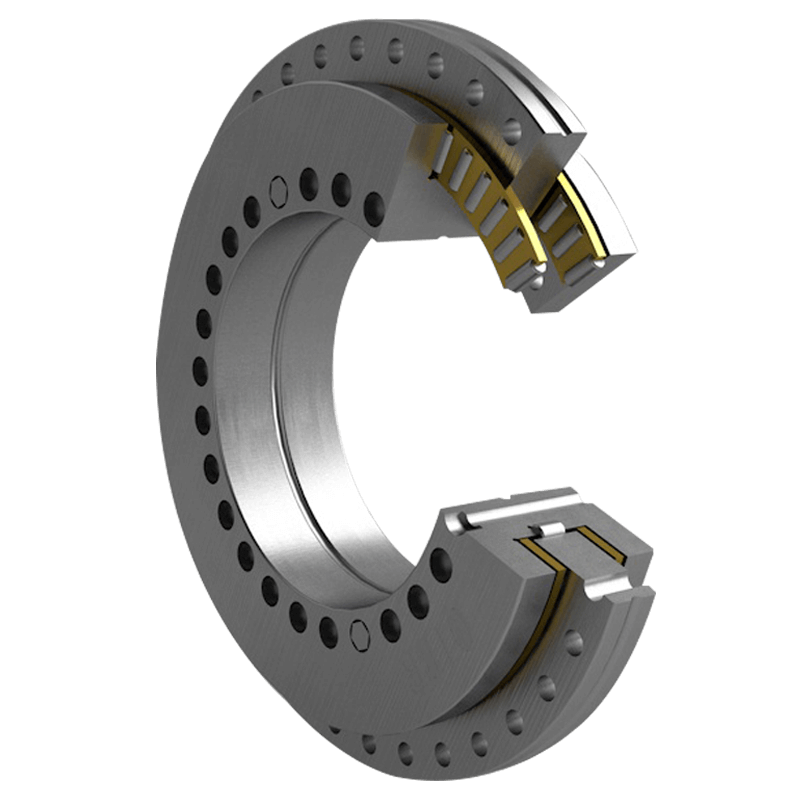

Main Bearings: Needle roller bearings are widely used in the main bearings of wind turbines to support the connection between the wind turbine and the generator. They must be able to withstand the huge radial and axial loads of wind turbines and provide smooth operation despite high-speed rotation.

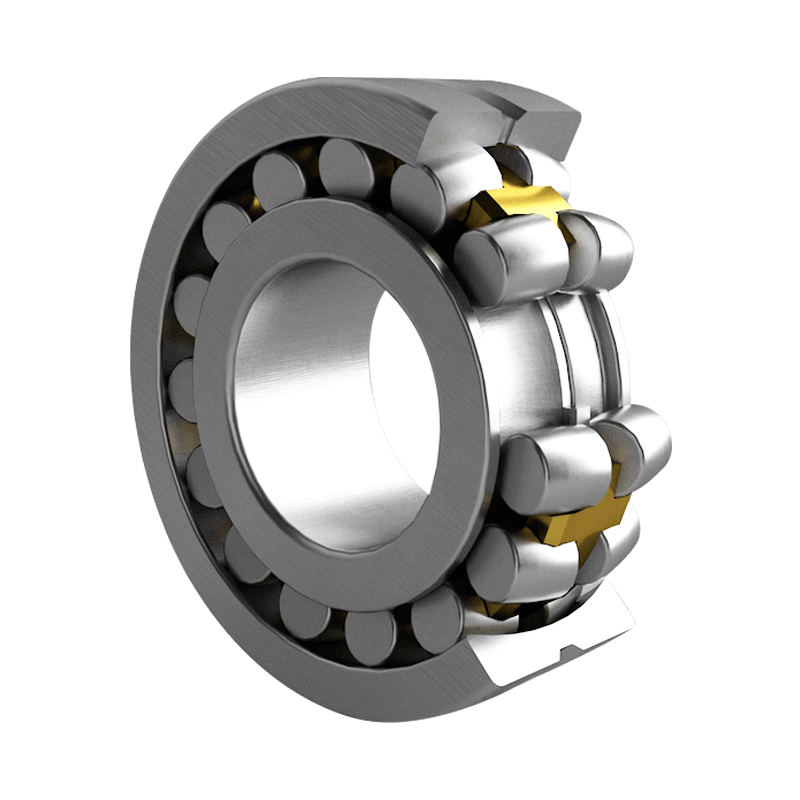

Generator Bearings: Generators within wind turbines often require support bearings to ensure rotation of generator components and power generation. Needle roller bearings are used to support generator rotors, allowing them to operate smoothly at high speeds and changing wind conditions.

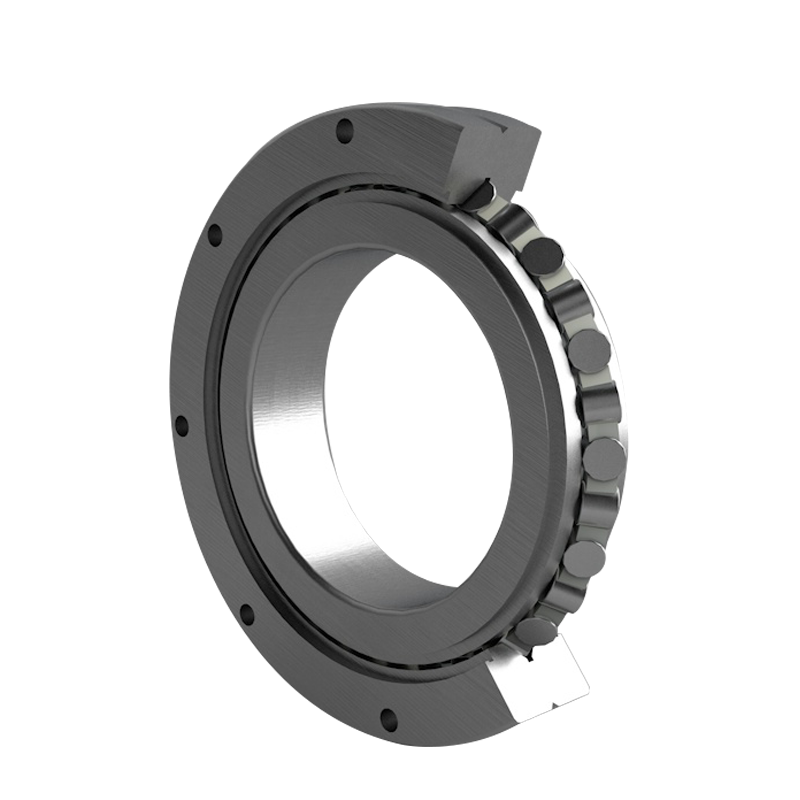

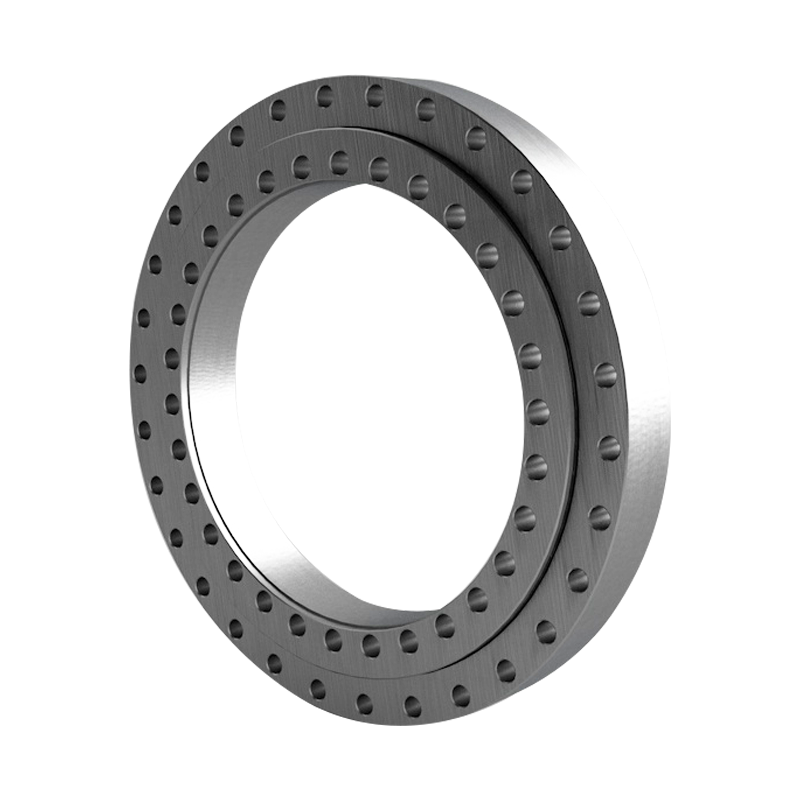

Yaw Bearing: Wind turbines are often equipped with a yaw system that positions the rotor to face the wind source. Needle roller bearings are used in yaw bearing systems to support the rotation and positioning of wind turbines.

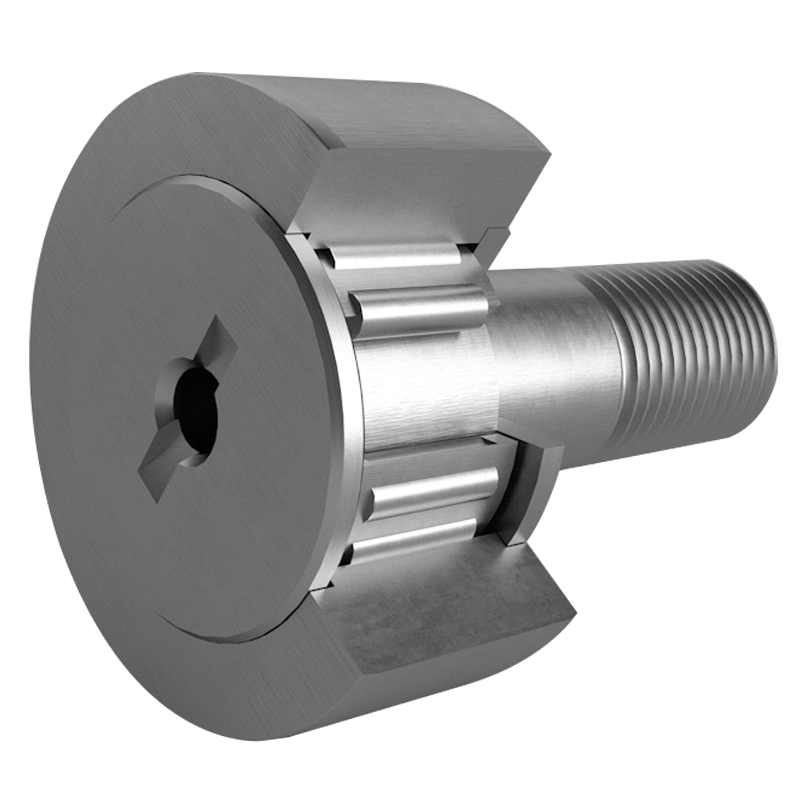

Pitch Mechanism: The blades of a wind turbine can often be adjusted in angle to optimize wind energy capture. The needle roller bearings in the pitch mechanism support the rotational motion of the blades, ensuring smooth and precise blade adjustment.

Tower Base Load-bearing Ring: The tower base load-bearing ring of a wind turbine usually uses needle roller bearings to support the rotation of the tower and wind wheel, while reducing resistance and improving rotation efficiency.

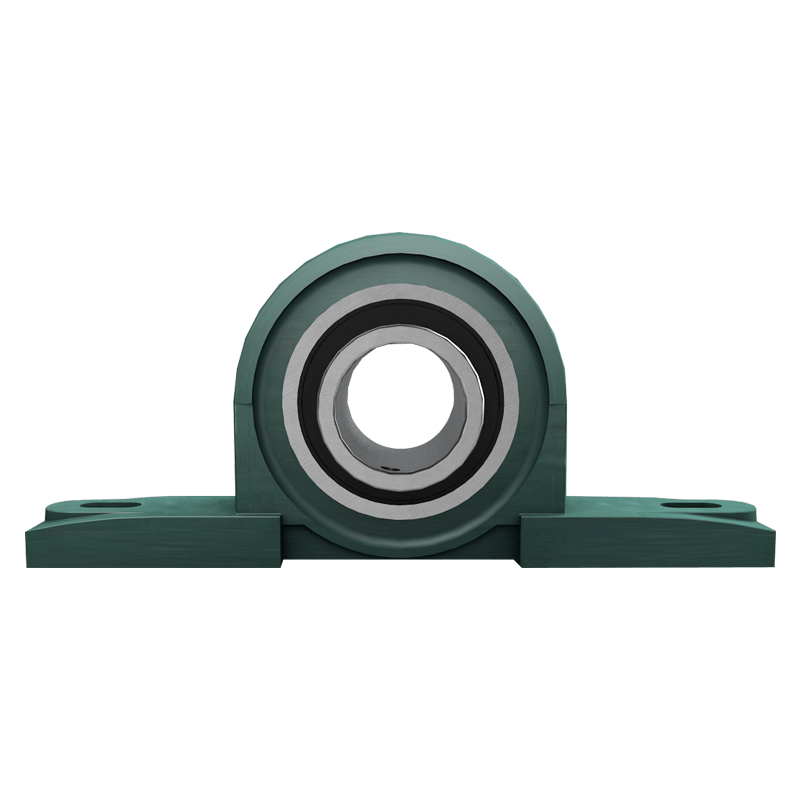

Rotor Flipping Device: Some wind turbines require the ability to flip the rotor for maintenance or shutdown. Needle roller bearings are often used to support rotor turning devices, ensuring safe and stable operation.

These are some of the key applications of needle roller bearings in wind turbines. Due to the harsh operating conditions of wind turbines, bearings must have high load carrying capacity, high reliability and long life. Therefore, bearing selection, installation and maintenance play a key role in the design and operation of wind turbines.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation