WEBINAR

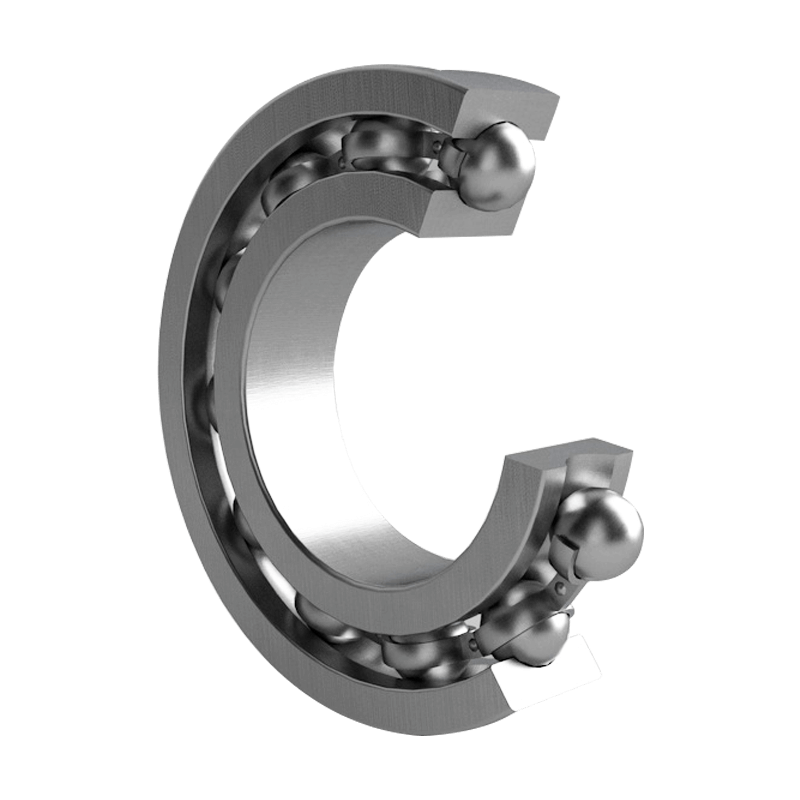

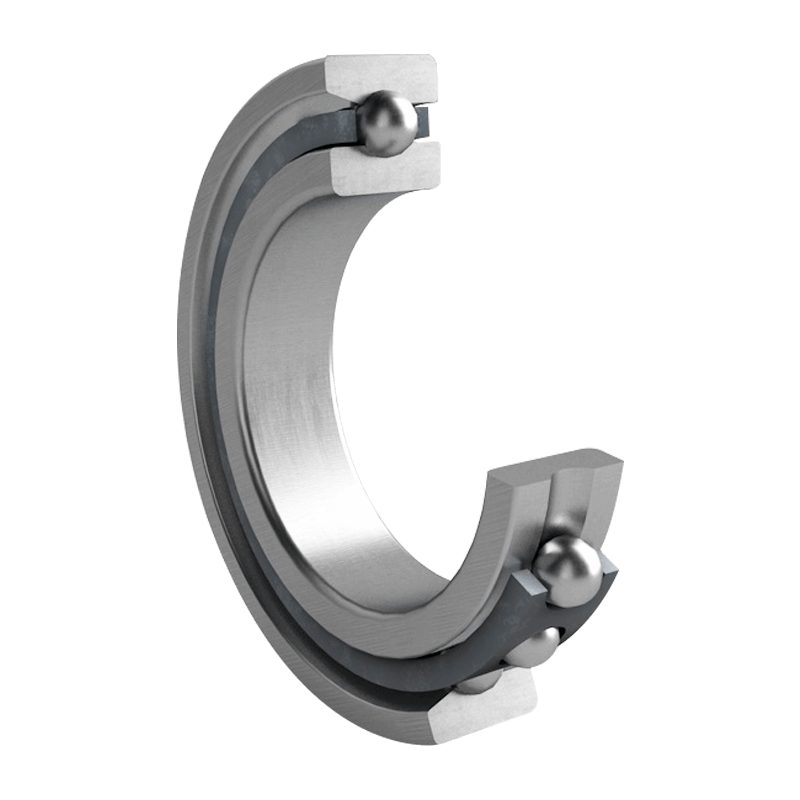

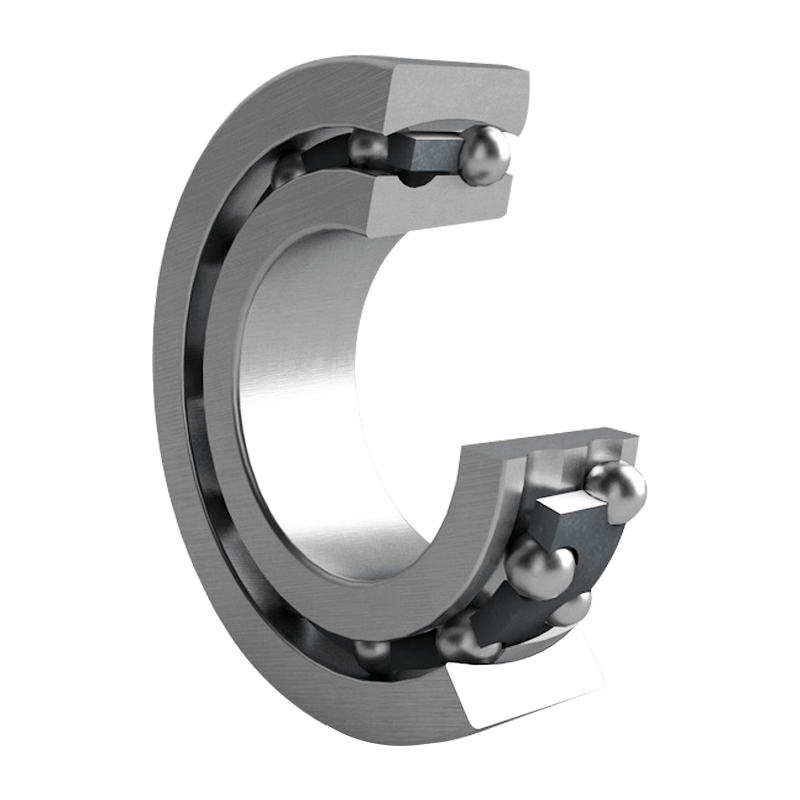

Deep Groove Ball Bearing

Learn More

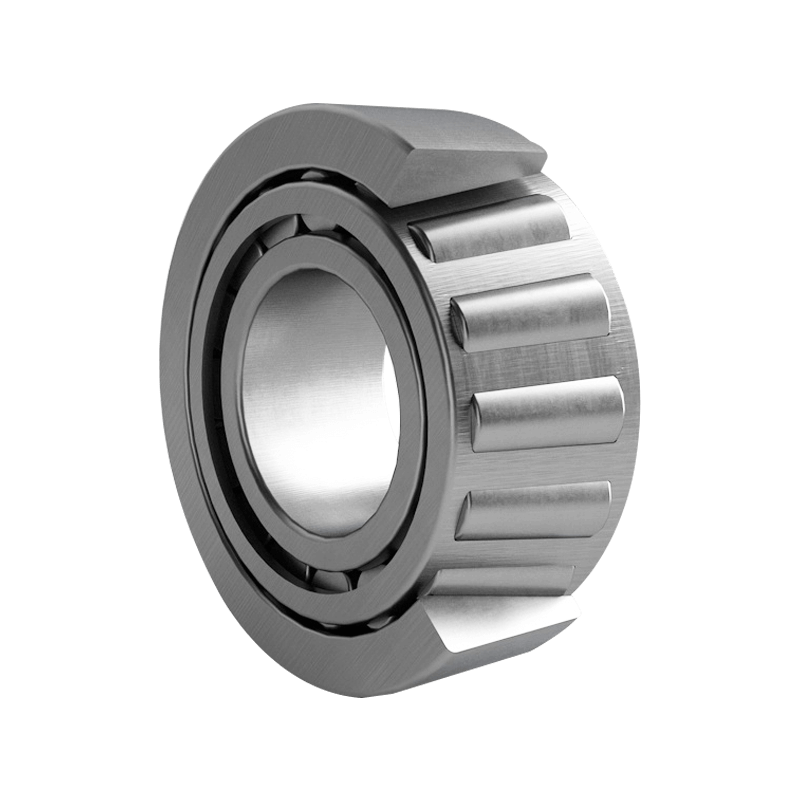

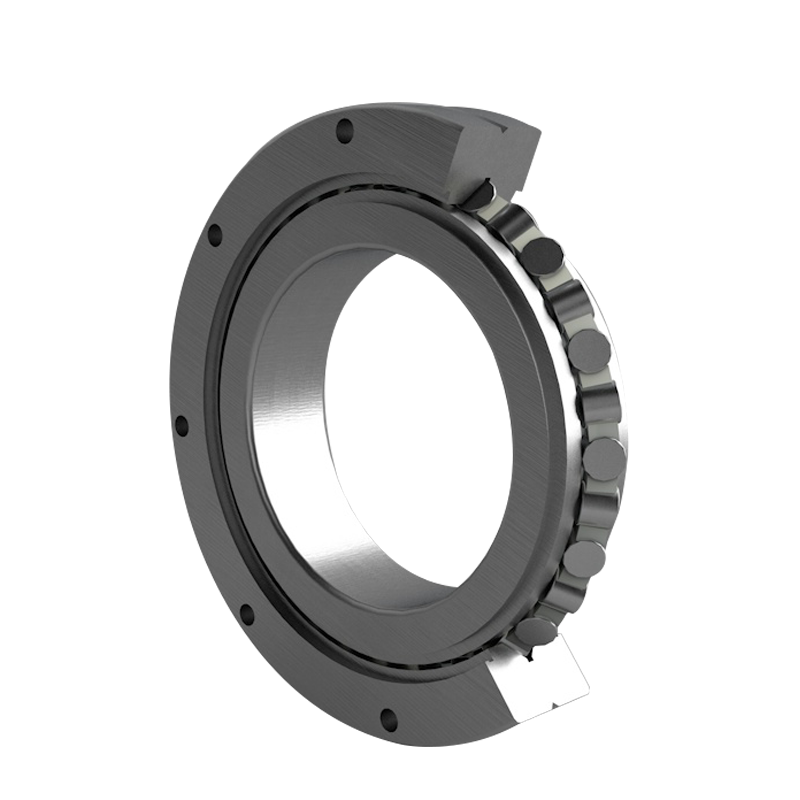

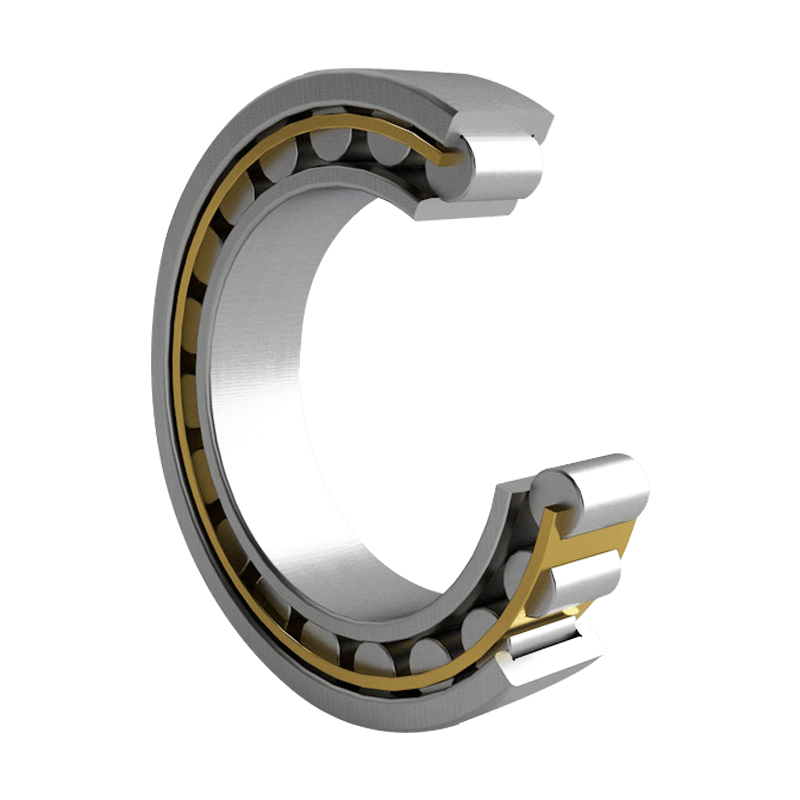

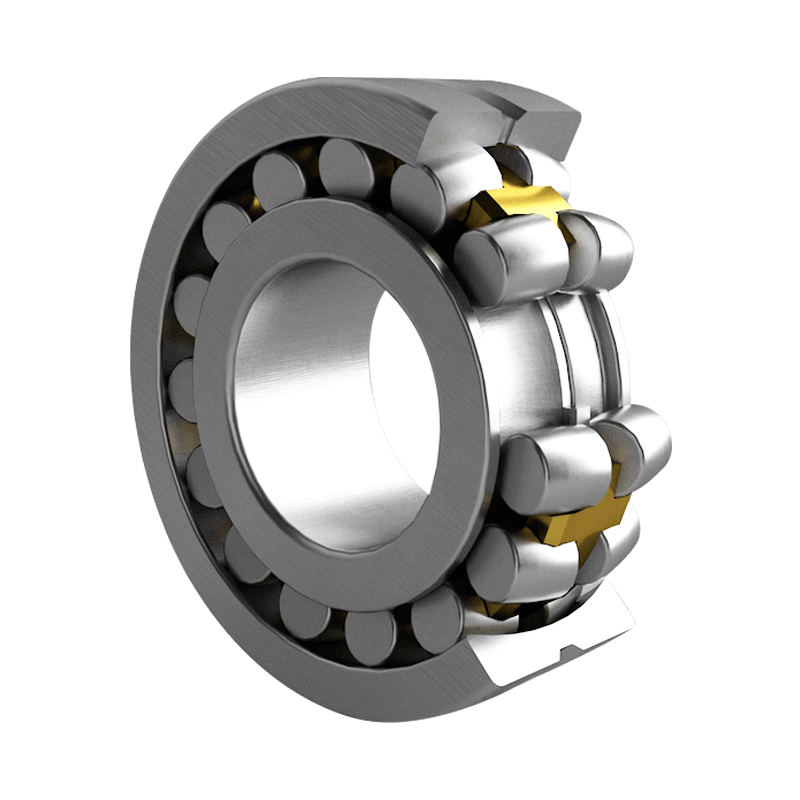

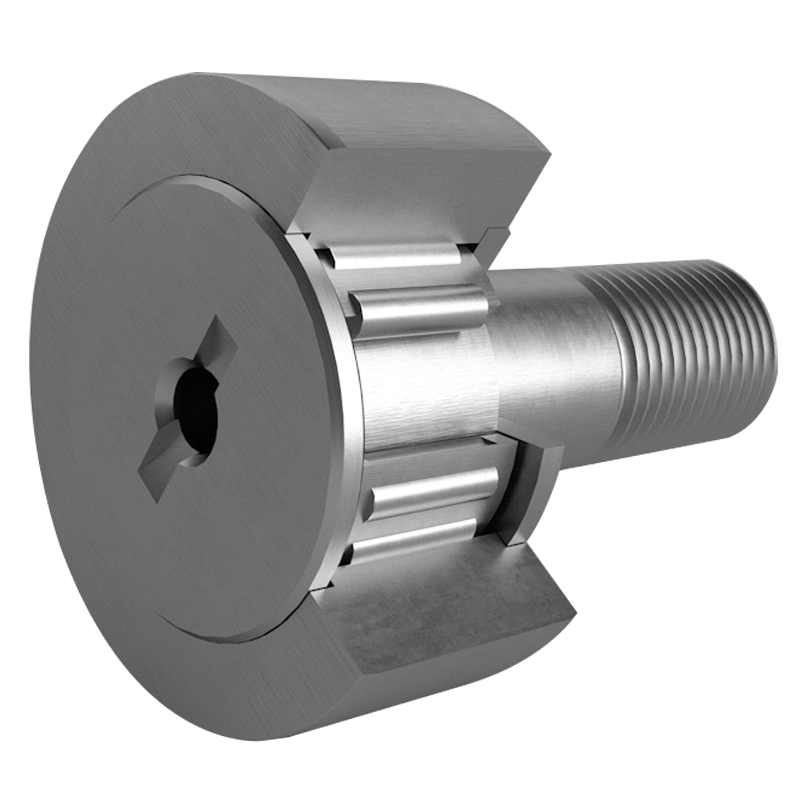

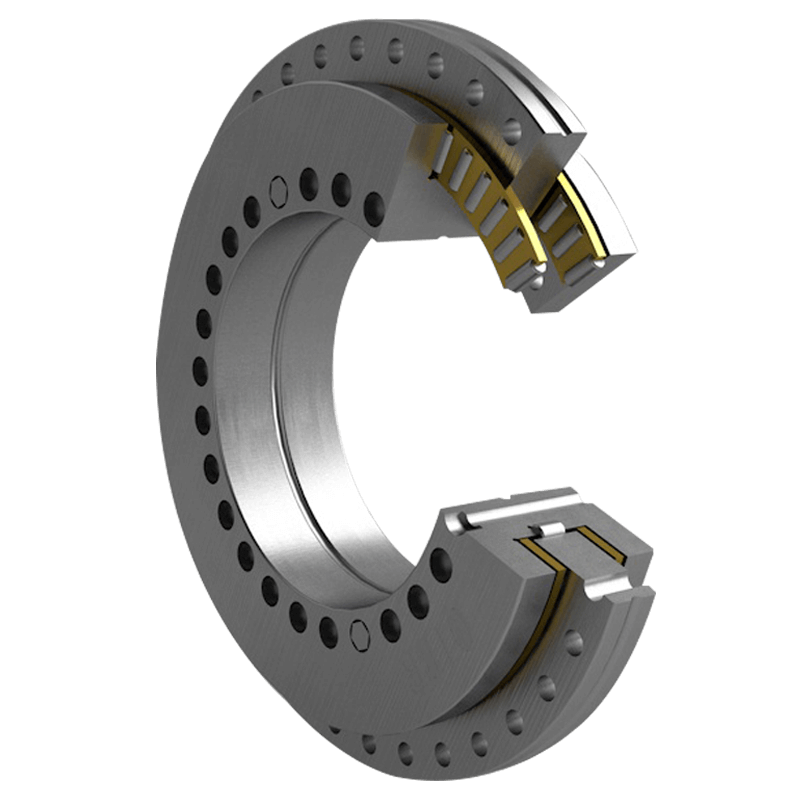

Cylindrical roller bearings are a common type of rolling bearings. Its basic structure and working principle are as follows:

Inner and Outer Rings: Cylindrical roller bearings usually consist of two rings, an inner ring and an outer ring. The inner ring is installed on the shaft, and the outer ring is installed on the bearing seat.

Rolling Elements: Between the inner and outer rings, there are many cylindrical rolling elements, which are key components of the bearing. They are usually cylindrical to reduce friction and support the rotation of the shaft.

Cage: The rolling elements are usually separated by a cage to ensure that they are evenly distributed in the bearing and to prevent collisions between them.

Sealing and Lubrication: Cylindrical roller bearings are often equipped with seals to prevent dust and impurities from entering the interior of the bearing. Lubricants are used to reduce friction and cool bearings.

The working principle of cylindrical roller bearings is based on the principle of rolling friction, which enables the bearings to support rotational motion and bear axial and radial loads. When an external load is applied to the bearing, the rolling elements roll between the inner and outer rings instead of sliding, thereby reducing friction and energy loss.

The working process is as follows:

When a rotational force or load is applied to the shaft, the cylindrical rollers on the inner ring begin rolling on the outer ring instead of sliding.

Due to small rolling friction, cylindrical roller bearings can operate at high speeds and loads and have a long life.

With proper lubrication and sealing, the inside of the bearing can be kept clean and protected from dust and impurities, extending the life of the bearing.

In summary, the basic structure and working principle of cylindrical roller bearings make them an important bearing type widely used in industrial and mechanical equipment, capable of effectively supporting various loads and rotational movements.

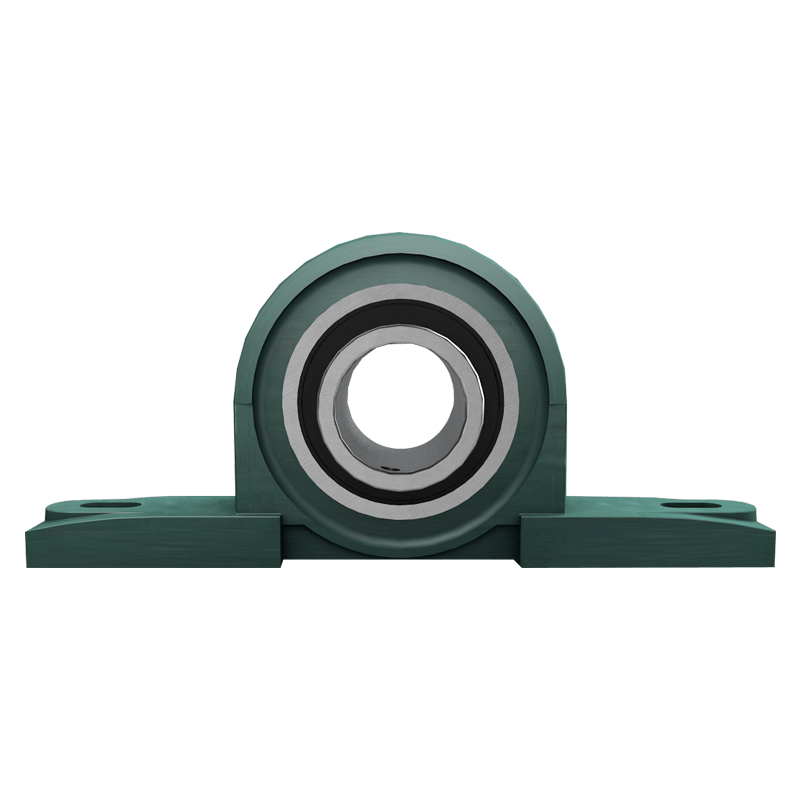

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation