WEBINAR

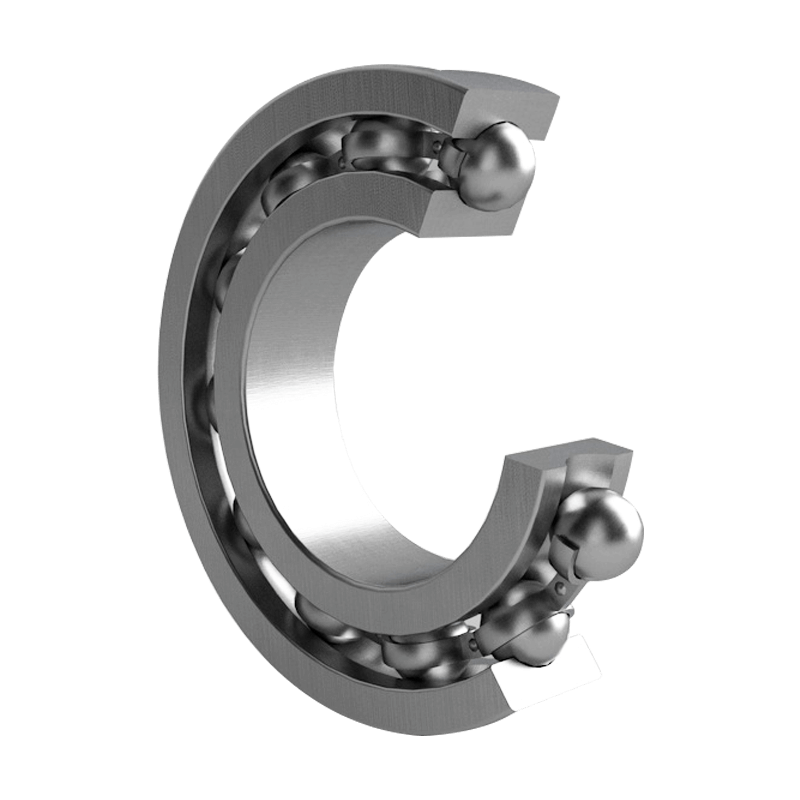

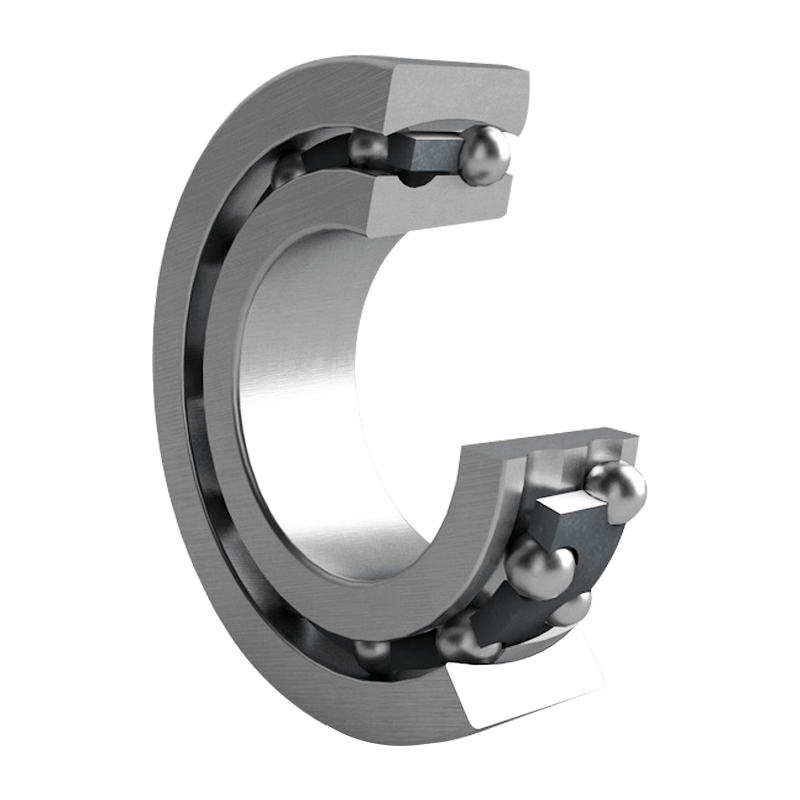

Deep Groove Ball Bearing

Learn More

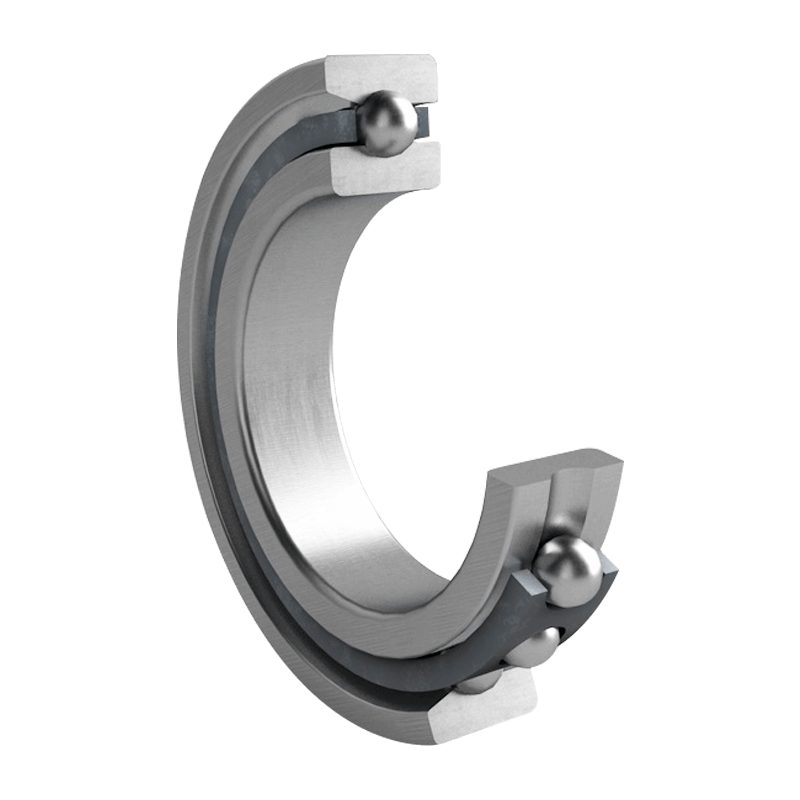

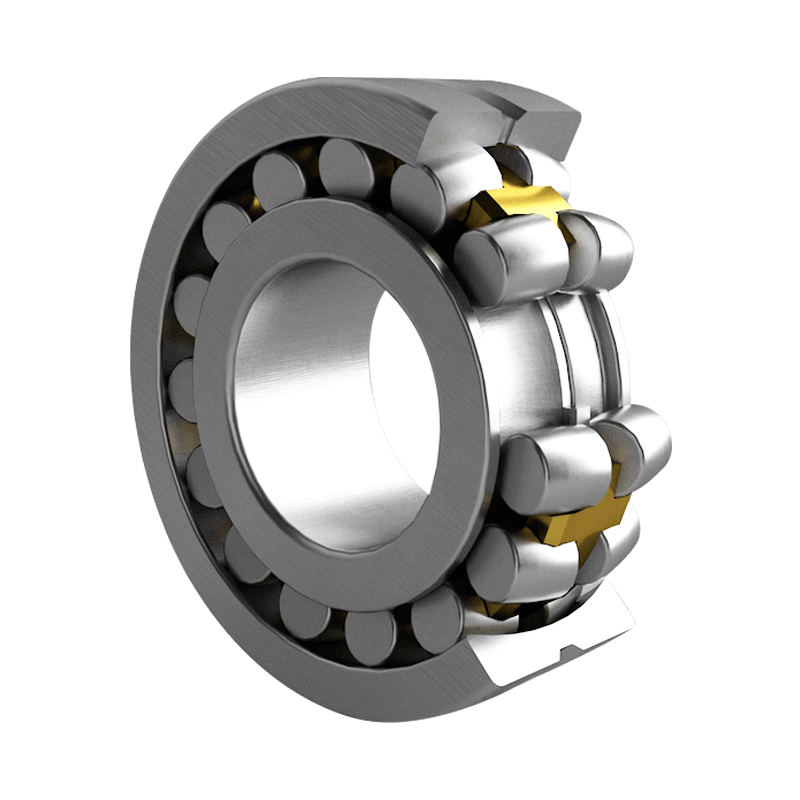

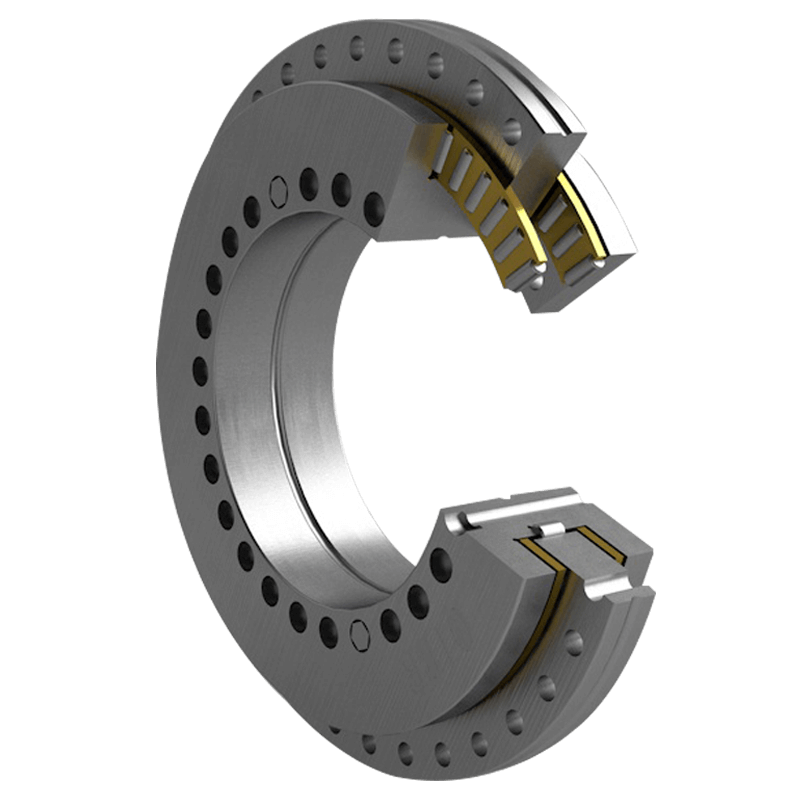

Self-aligning ball bearing is a common rolling bearing. Its basic structure and working principle are as follows:

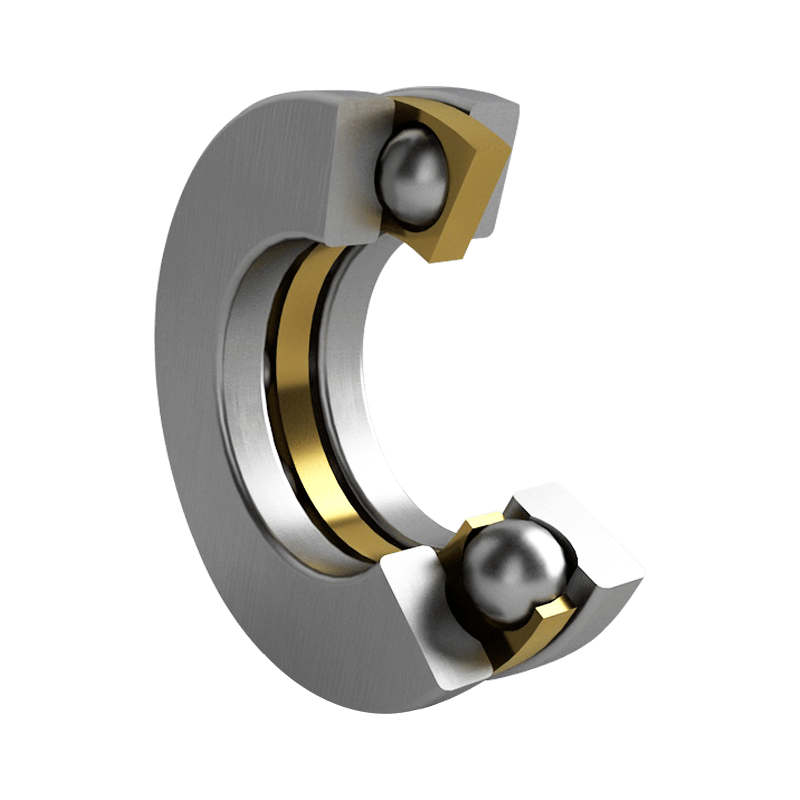

Self-aligning ball bearings are mainly composed of the following parts:

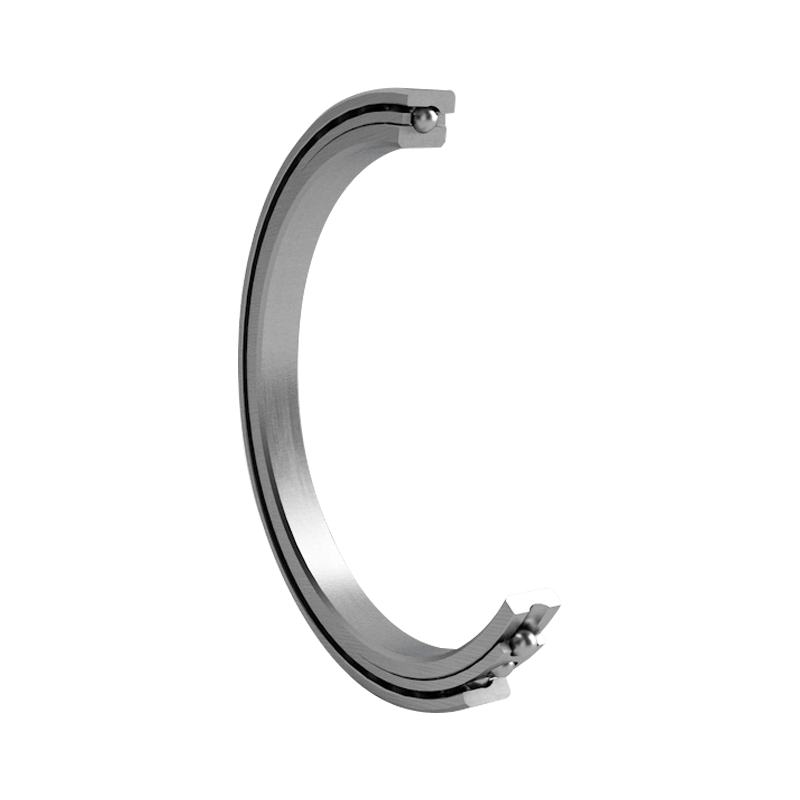

Outer Ring: The outer ring is the outer annular part of the bearing and is usually a spherical shape. It facilitates the mounting and alignment of bearings to the outside.

Inner Ring: The inner ring is the inner annular part of the bearing and is usually a cylindrical shape. It is mounted on the shaft and rotates with it.

Rolling Elements: Rolling elements are spheres between the inner and outer rings. These spheres allow the bearing to roll under load, reducing friction and wear.

Cage: Cage is a component, usually a metal or plastic structure, used to keep rolling elements evenly spaced.

Self-aligning ball bearings are called "self-aligning" because they have a certain self-aligning ability and can adjust the mounting position of the bearings within a certain range to adapt to shaft deviation or change.

When external loads are applied to the bearings, self-aligning ball bearings work as follows:

Loads act on the bearings, which causes relative motion between the inner and outer rings. Due to the presence of rolling elements, the load is evenly distributed inside the bearing, thereby reducing friction and wear. If the bearing is subjected to shaft deflection or slight tilting, the balls of the self-aligning ball bearing are free to roll between the inner and outer rings to self-align, thus keeping the load balanced.

These self-aligning characteristics make self-aligning ball bearings ideally suited to application scenarios that require a certain amount of shaft deviation from the external structure, such as vibration or shaft instability in machinery and equipment.

In summary, self-aligning ball bearings have good self-aligning properties for a wide range of industrial applications and perform particularly well in situations where there are slight changes in load direction or vibration. This makes it an important component in many equipment and machinery systems.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation