WEBINAR

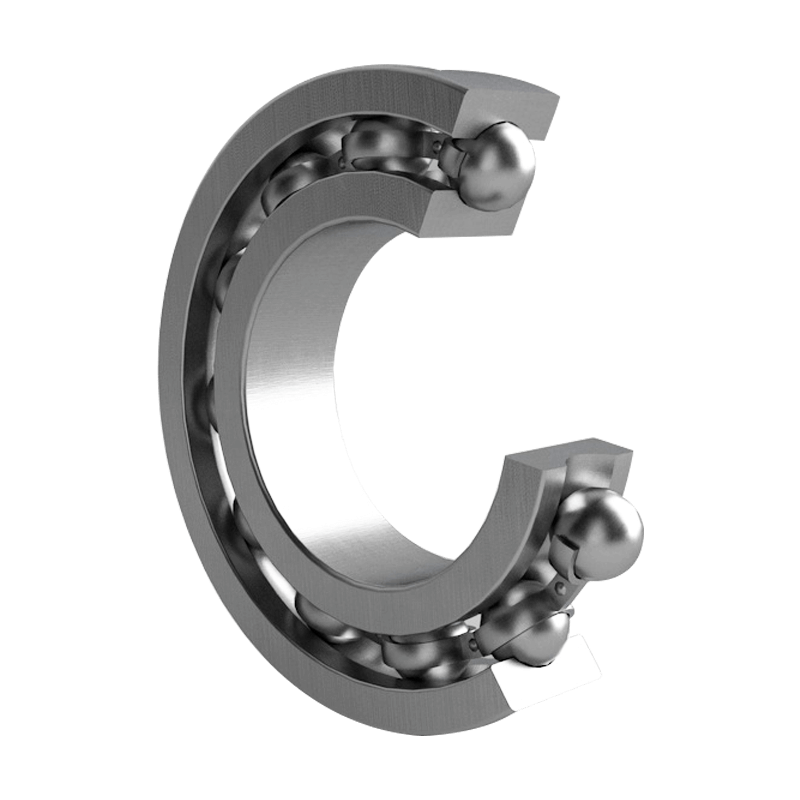

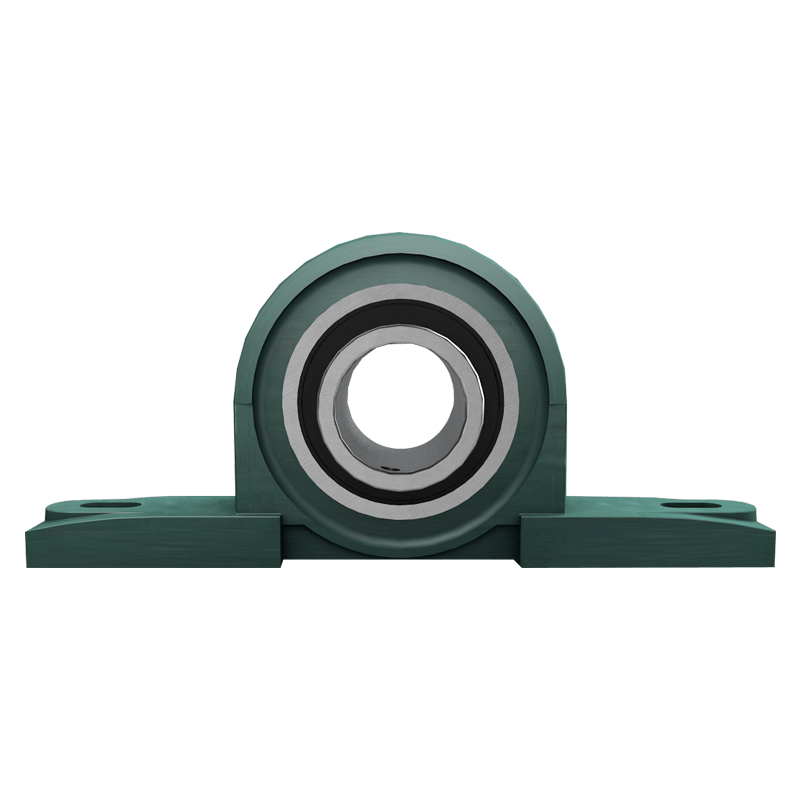

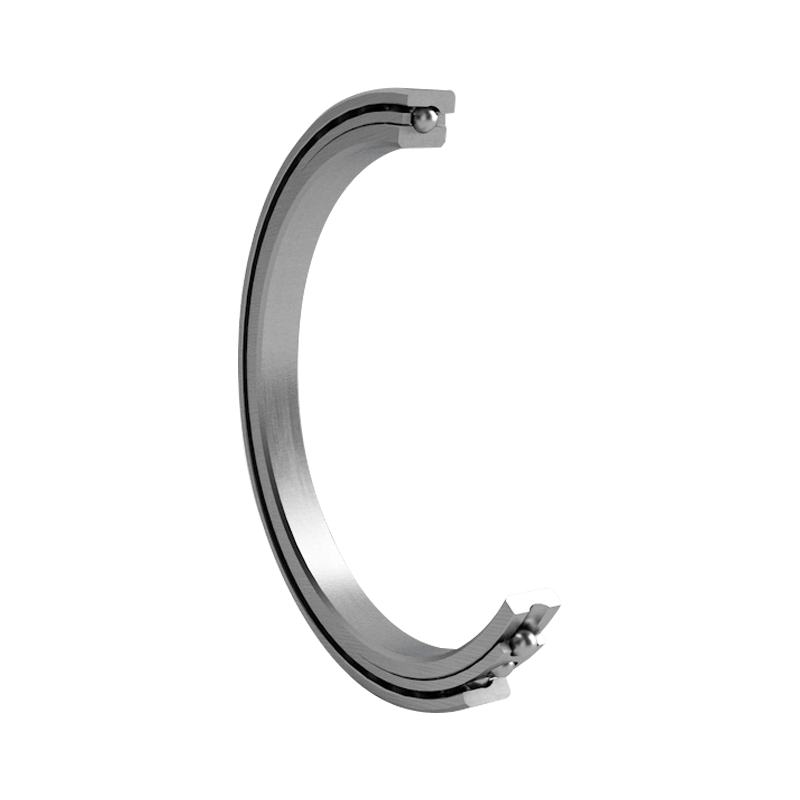

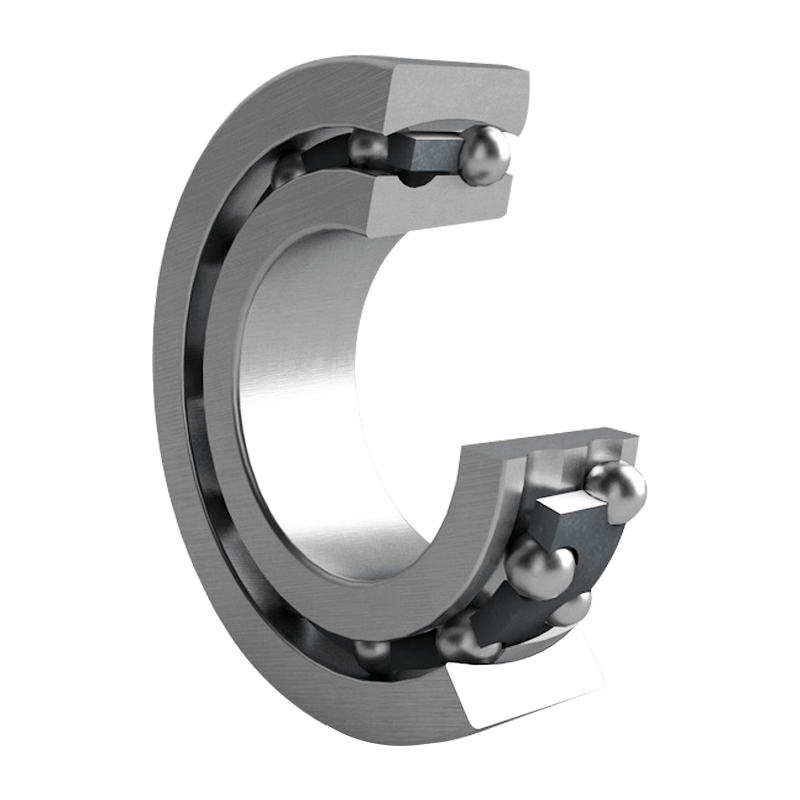

Deep Groove Ball Bearing

Learn More

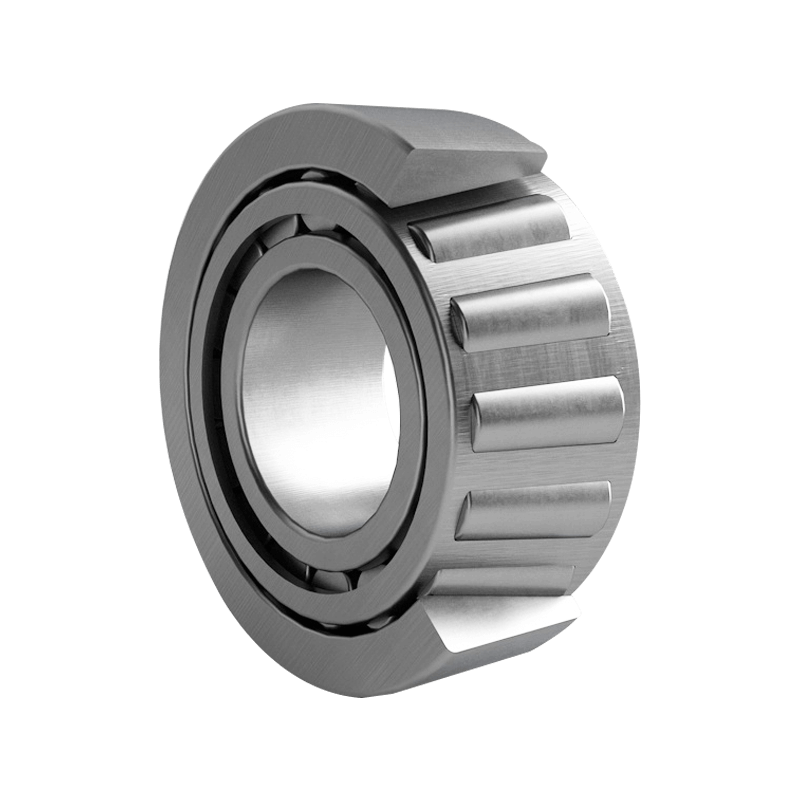

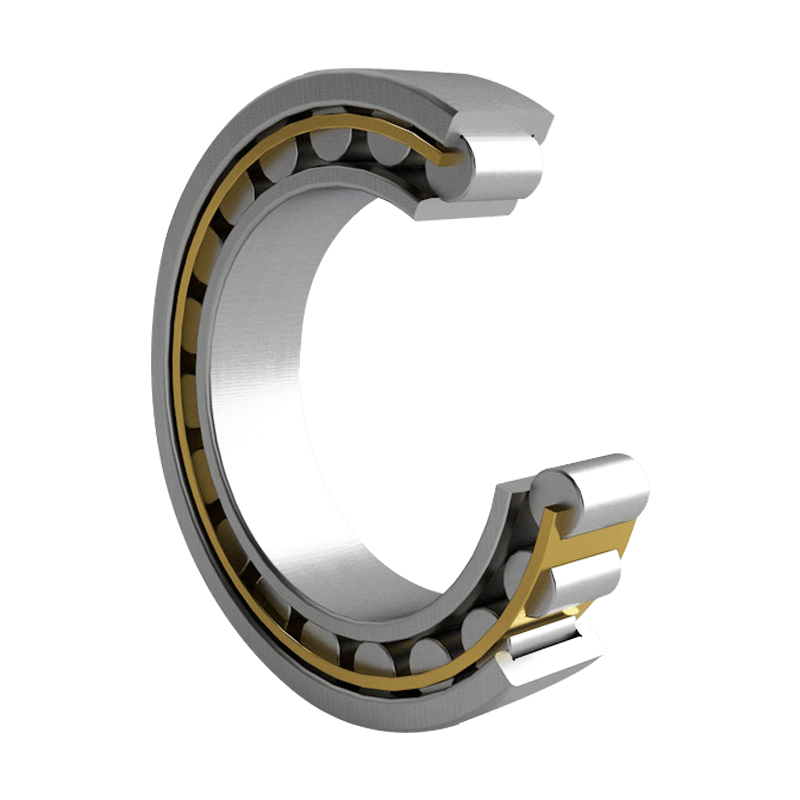

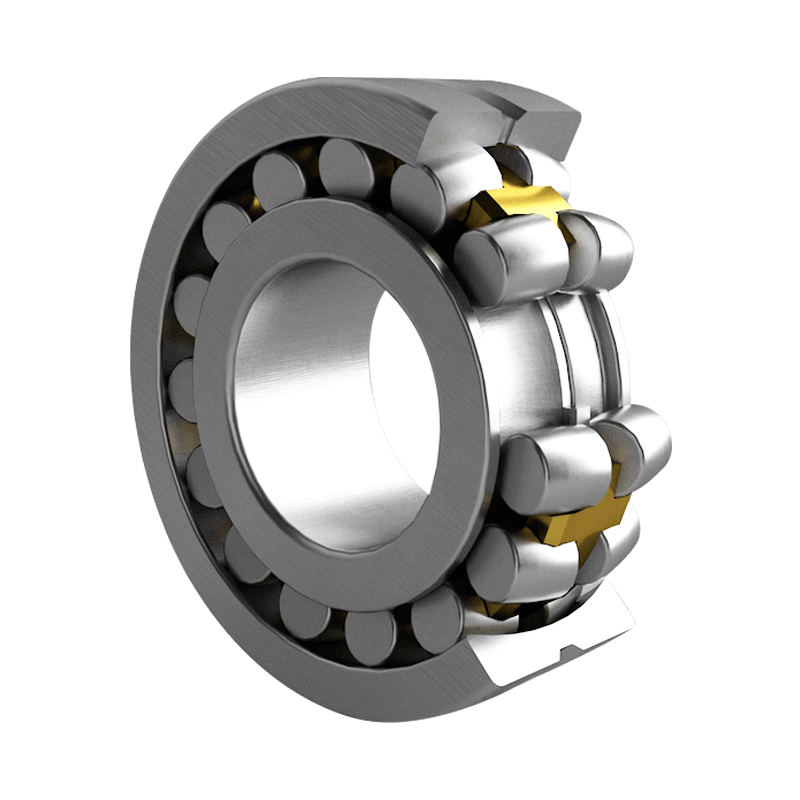

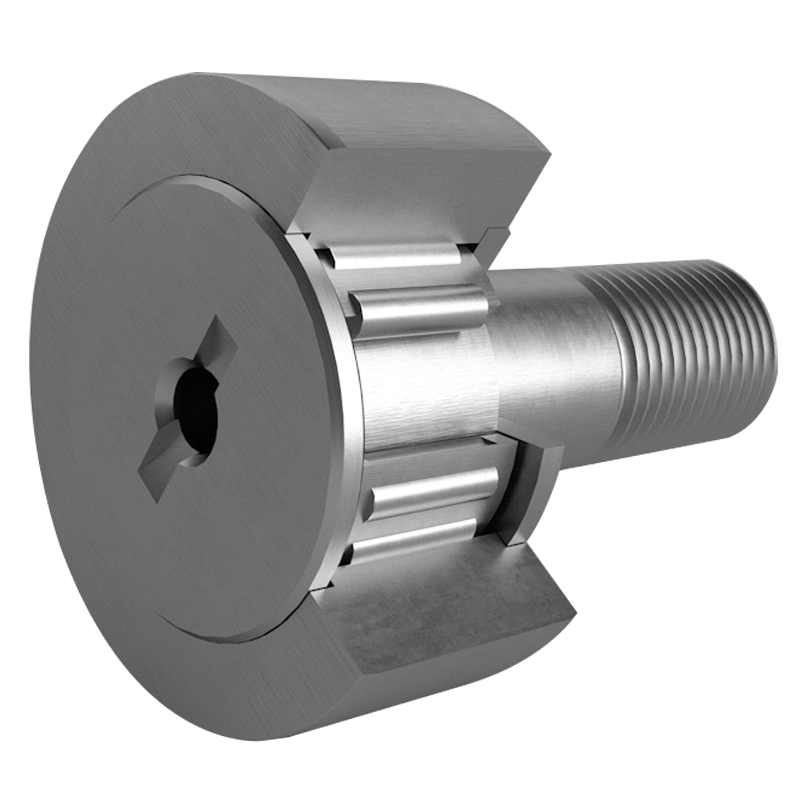

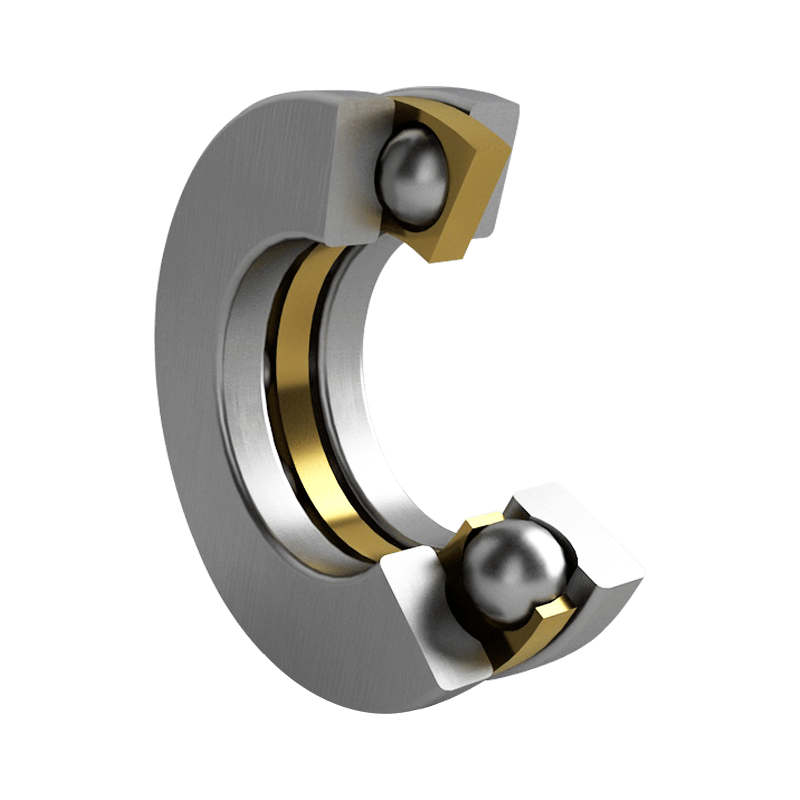

Needle roller bearing is a kind of rolling bearing widely used in industrial fields. Its basic working principle is to reduce friction through rolling and support the rotating shaft or bearing frame to support and transmit the load.

The following is the basic working principle of needle roller bearings:

Rolling Reduces Friction: The key feature of needle roller bearings is that there are many long needle rollers inside the bearing. These rollers are arranged in one or more rows and distributed along the inner circumference of the bearing. When a load is applied to the bearing, the rollers can roll between the inner and outer rings instead of creating friction like a plain bearing. This rolling motion significantly reduces friction losses, which makes the bearings more efficient and durable.

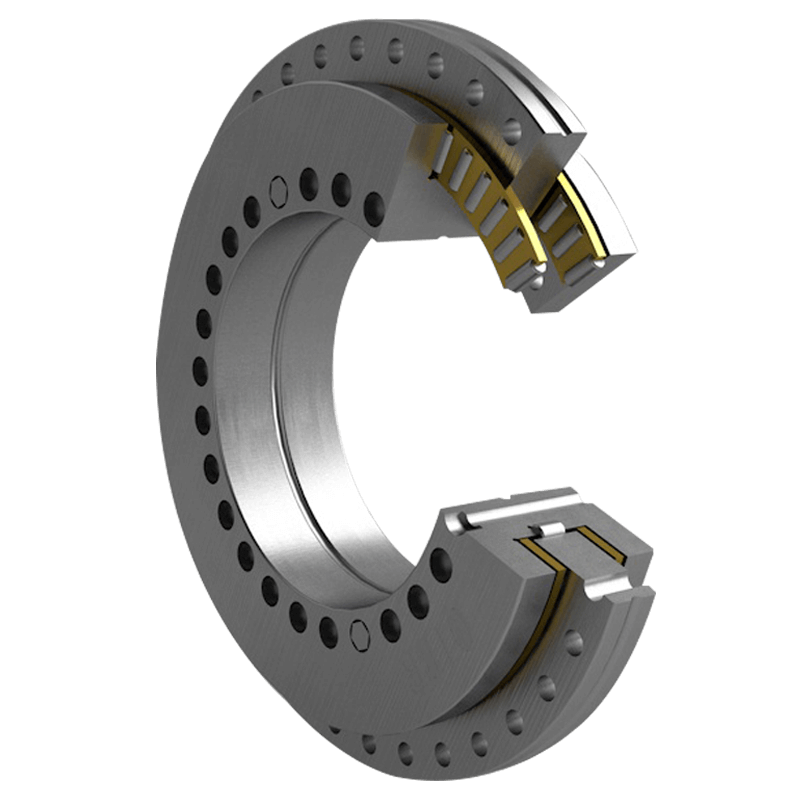

Distributing and Transmitting Load: The load is transmitted through the inner ring of the bearing to the needle rollers, and then distributed by the rollers to the outer ring of the bearing. This even distribution of load enables high load-carrying capacities, which makes needle roller bearings suitable for carrying large and complex loads.

Reduce Axial Loads: Needle roller bearings are typically used to carry axial loads, which are loads along the axis. Due to the relatively large length of needle rollers, they are able to effectively carry axial loads without compromising bearing performance.

Supports High-speed Rotation: The rolling pattern of needle roller bearings enables them to support high-speed rotation because there is less rolling friction between the rollers and less heat is generated.

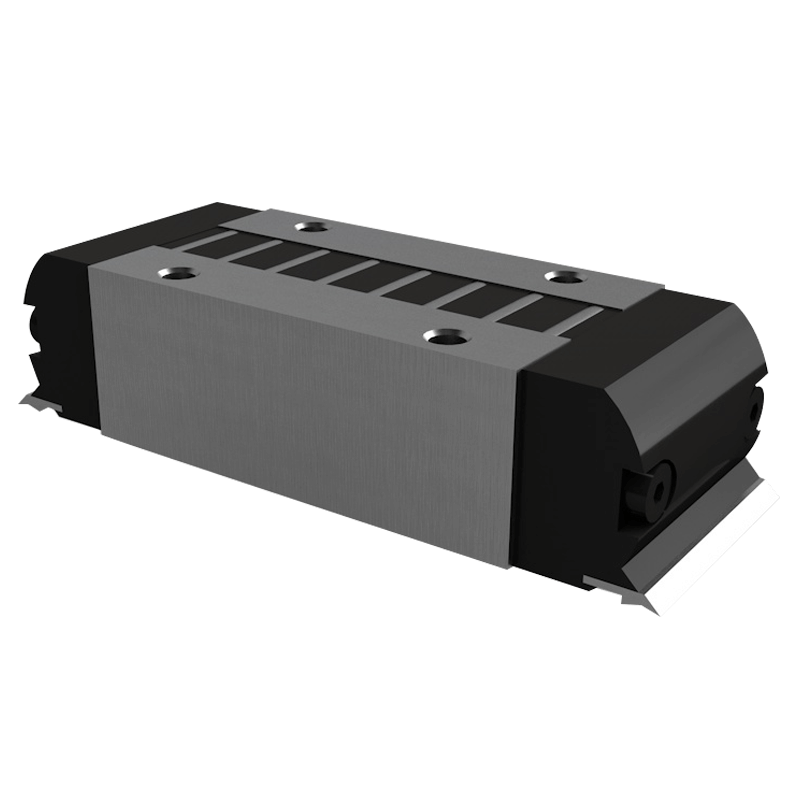

Suitable for Limited Spaces: The small radial cross section and high radial load carrying capacity of needle roller bearings make them suitable for limited installation spaces, such as machine tools, automotive transmissions and aircraft engines.

In summary, the working principle of needle roller bearings is to reduce friction, disperse and transfer loads through rolling, thus supporting applications with high efficiency, high load-bearing capacity and high-speed rotation. This makes it widely used in industrial fields, especially where high-performance bearings are required.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation