WEBINAR

Deep Groove Ball Bearing

Learn More

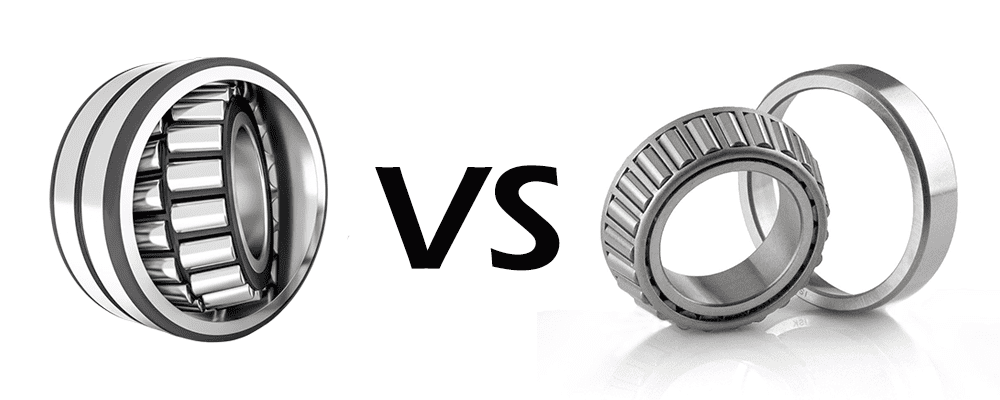

Tapered roller bearings and spherical roller bearings are both common types of rolling bearings, and they have some different characteristics and advantages in different applications.

The following is their comparative analysis:

Tapered Roller Bearings: Tapered roller bearings have tapered rollers and the rolling surfaces of the inner and outer rings are tapered. This structure makes them suitable for bearing radial and axial loads, as well as larger angular contact.

Spherical Roller Bearings: Spherical roller bearings have round rollers and the rolling surfaces of the inner and outer rings are spherical. They are mainly used to withstand large radial loads and usually not suitable for high axial loads.

Tapered Roller Bearings: Due to their angular contact design, tapered roller bearings have a higher axial load capacity and are more suitable for applications that require both radial and axial loads.

Spherical Roller Bearings: Spherical roller bearings are good at withstanding pure radial loads, but have lower capacity for axial loads.

Tapered Roller Bearings: Tapered roller bearings typically have high precision and stiffness and are suitable for applications which require high precision performance and greater stiffness.

Spherical Roller Bearings: Spherical roller bearings typically have lower accuracy and stiffness and are suitable for applications where these characteristics are less stringent.

Tapered Roller Bearings: The mounting and adjustment of tapered roller bearings can be complicated, requiring consideration of the tilt angle of the inner and outer rings and the front and rear clearance.

Spherical Roller Bearings: Spherical roller bearings are usually relatively easy to mount and adjust without excessive angular adjustment.

Tapered Roller Bearings: Tapered roller bearings are commonly used in applications that require both radial and axial loads, such as automotive differentials, transmission systems in construction machinery, etc.

Spherical Roller Bearings: Spherical roller bearings are mainly used in some applications where the radial load requirement is high and the axial load is small, such as wind turbines and motors.

In summary, the choice of tapered roller bearings or spherical roller bearings depends on the requirements of the specific application, including factors such as the type of load, load size, accuracy requirements and mounting difficulty. Each type of bearing has its own unique advantages and limitations, and the choice needs to be made according to the actual situation.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation