WEBINAR

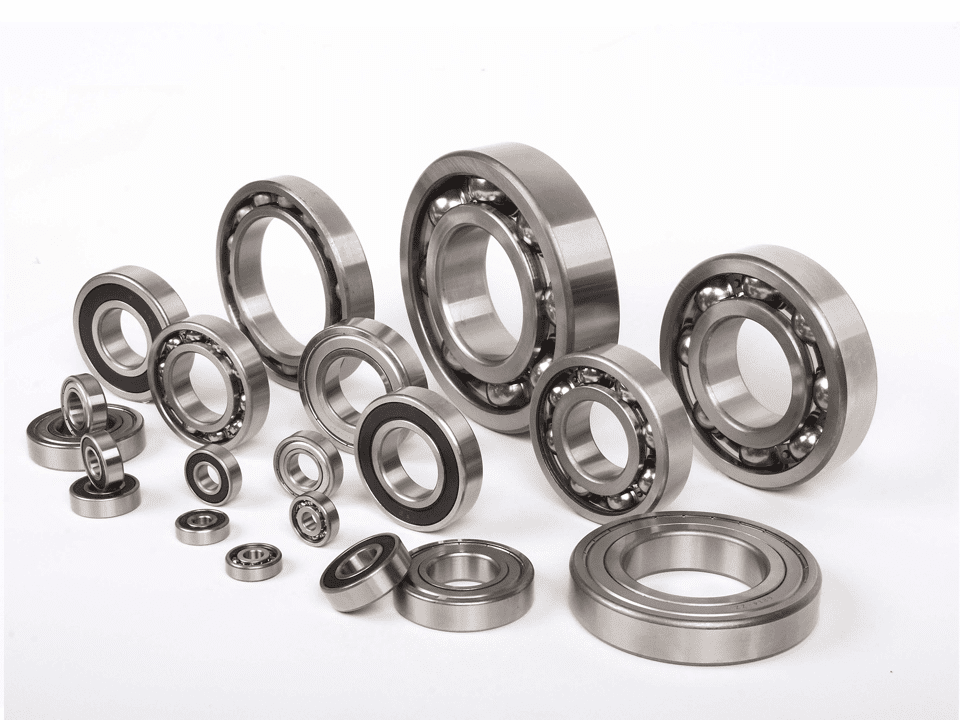

Deep Groove Ball Bearing

Learn More

The design and manufacture of deep groove ball bearings is a precise process involving multiple standard and highly specialized manufacturing steps. These standards and processes ensure performance, reliability and consistency of the bearings. This article will explore the design standards and manufacturing processes of deep groove ball bearings.

International and Regional Standards: The design of deep groove ball bearings follows multiple international and regional standards, such as ISO (International Organization for Standardization), DIN (German Industrial Standards) and JIS (Japanese Industrial Standards).

Dimensional Accuracy: The dimensional accuracy and tolerances of bearings are designed based on their intended use and application. These parameters determine the fit of the bearing to the shaft and housing.

Load Capacity: Design bearings based on the load requirements of application, including radial and axial loads.

Speed Grade: The maximum operating speed of the bearing must also be considered during design.

Lubrication and Sealing: The design must consider the suitable lubrication (oil or grease) and sealing requirements.

Raw Material Preparation: Usually use high carbon chromium steel and other materials. These materials are heat treated to increase their hardness and wear resistance.

Precision Machining: Use high-precision machine tools to process the inner and outer rings and rolling elements of the bearing.

Heat Treatment: Enhance the hardness and durability of the material. Usually involve quenching and tempering processes.

Grinding and Polishing: Ensure bearing components achieve the required dimensional accuracy and surface finish.

Assembly: Assemble inner and outer rings, rolling elements and cages in a clean and controlled environment.

Lubrication and Sealing: Add lubricant and install seals according to design requirements.

Quality Inspection: There is strict quality control at every manufacturing stage, including dimensional inspection, material testing and functional testing.

The design and manufacturing of deep groove ball bearings is a process involving multiple standards and complex processes. Following these standards and precise manufacturing steps is key to ensuring bearing quality, performance and reliability. High-quality deep groove ball bearings are essential for the smooth operation and long-term stability of various mechanical equipment.

Understanding the design standards and manufacturing processes of deep groove ball bearings is important for engineers to select the correct bearing, conduct failure analysis, and optimize equipment performance.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation