WEBINAR

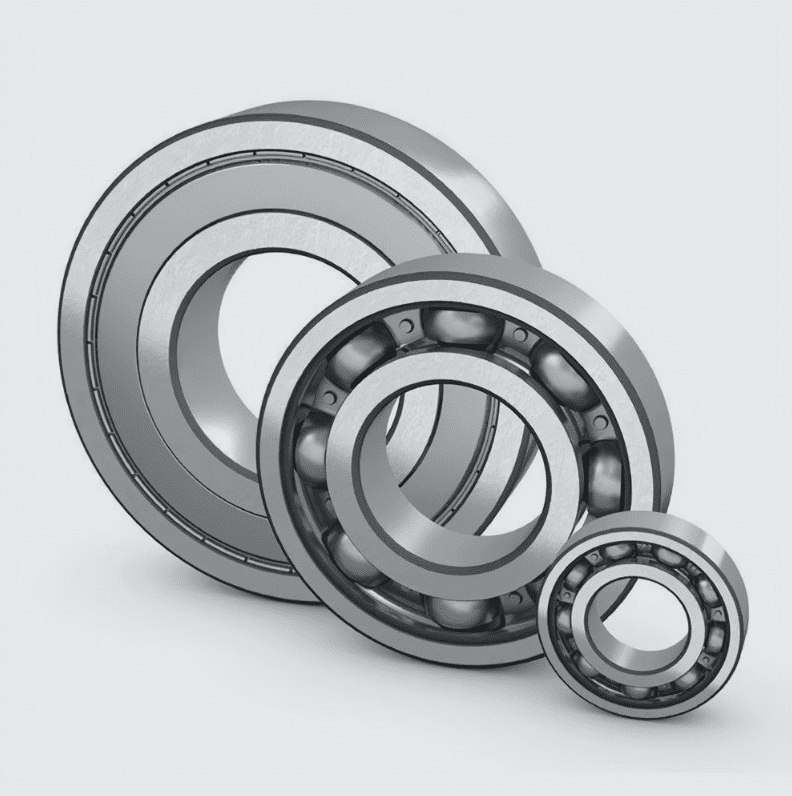

Deep Groove Ball Bearing

Learn More

Dimension classification and correct identification of deep groove ball bearings are critical to ensuring that the bearing will meet the needs of a specific application. Accurate identification of bearing dimensions aids in maintenance, replacement and optimization of machine performance. This article will explore the dimensional classification and identification methods of deep groove ball bearings.

Basic Dimensions: The dimensions of deep groove ball bearings usually include inner diameter (ID), outer diameter (OD) and width (B). These dimensions determine the matching of the bearing to the shaft and housing.

International Standards: Bearing dimensions usually follow ISO (International Organization for Standardization) standards. For example, 6000 series (light duty), 6200 series (medium duty) and 6300 series (heavy duty).

Dimension Series: Dimension series indicates the size and load capacity of the bearing. The larger the number, the higher the load-carrying capacity of the bearing.

Model Designation: Bearings usually have model designations, which contain the main dimensions and series information of the bearing.

For example, 6205 represents a medium-sized series bearing with an inner diameter of 25mm.

Measure Dimensions: If there is no obvious model number on the bearing or the model number is worn, you can directly measure the inner diameter, outer diameter and width. Use calipers or other precision measuring tools to take measurements.

Manufacturer's Catalog: Referring to the manufacturer's catalog or online database can help identify bearing models and sizes.

Check Other Markings: Some bearings may also have other markings, such as material code, accuracy grade, lubrication type, and seal type.

When measuring and identifying bearing dimensions, it is important to the accuracy. Because even small errors can render a bearing unsuitable for the application. The identification process should pay attention to the overall condition of the bearing, such as wear, corrosion or damage, which may affect replacement and maintenance decisions.

Understanding the dimension classification and correct identification methods of deep groove ball bearings is very important to ensure efficient and reliable operation of mechanical equipment. Whether performing maintenance, replacement or upgrades, accurately identifying bearing dimensions is a critical step.

Master the knowledge of the dimensional identification of deep groove ball bearings is useful for maintenance personnel and engineers, which helps them make more informed decisions during repair and design processes.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation