WEBINAR

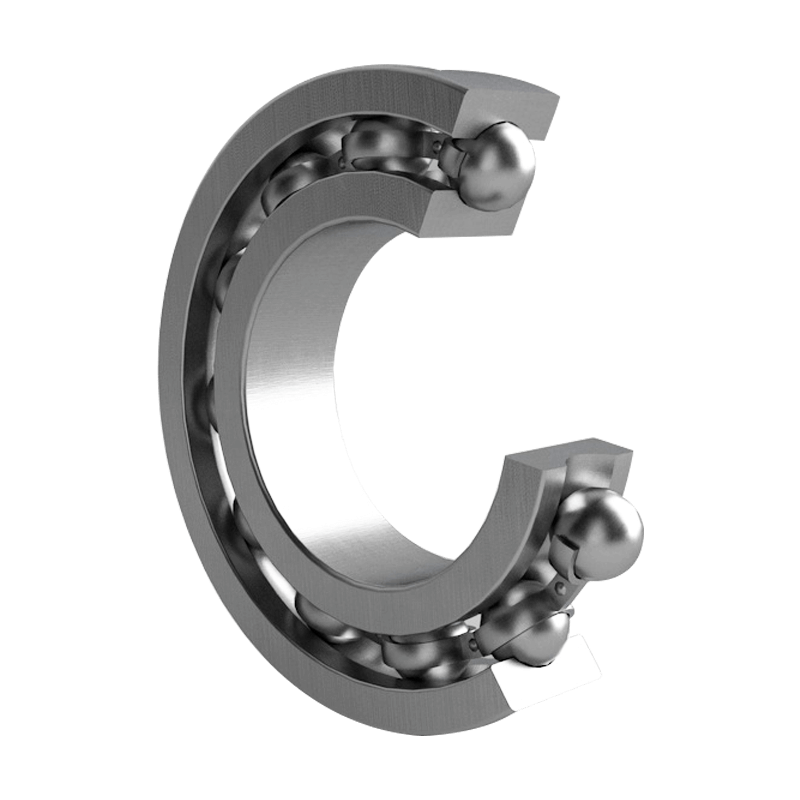

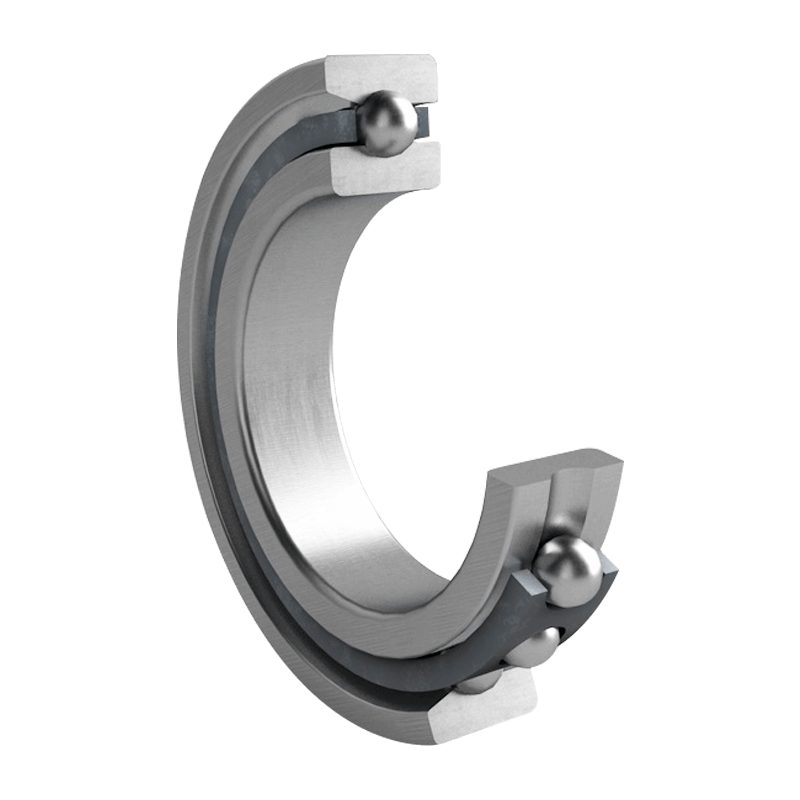

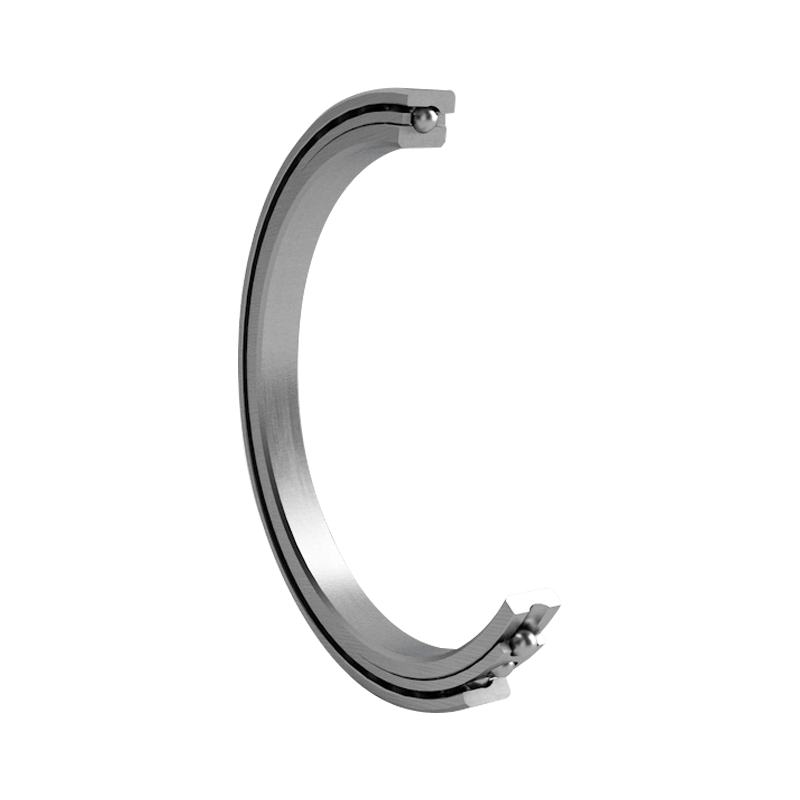

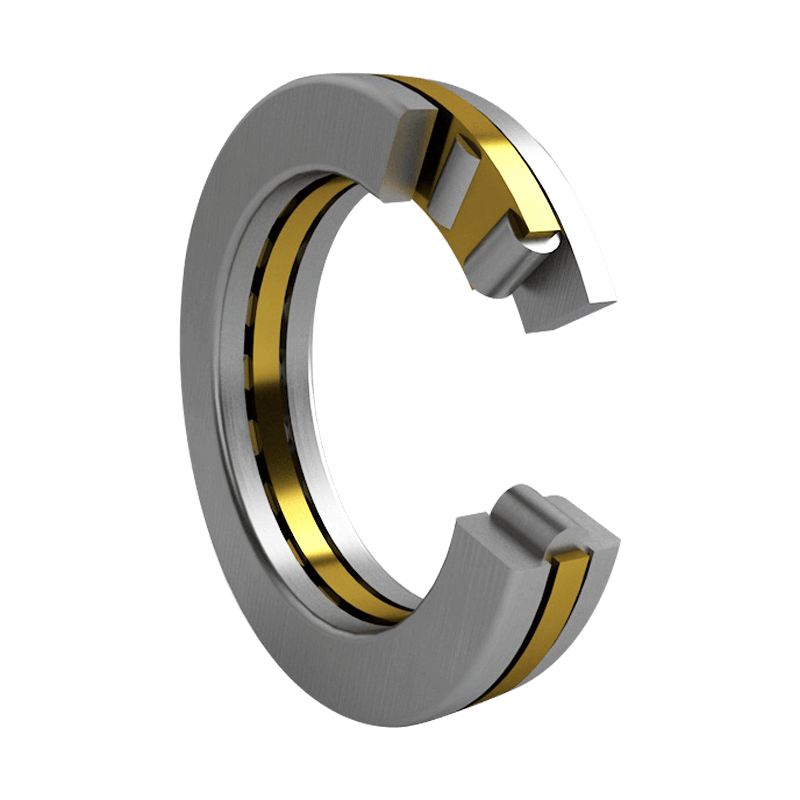

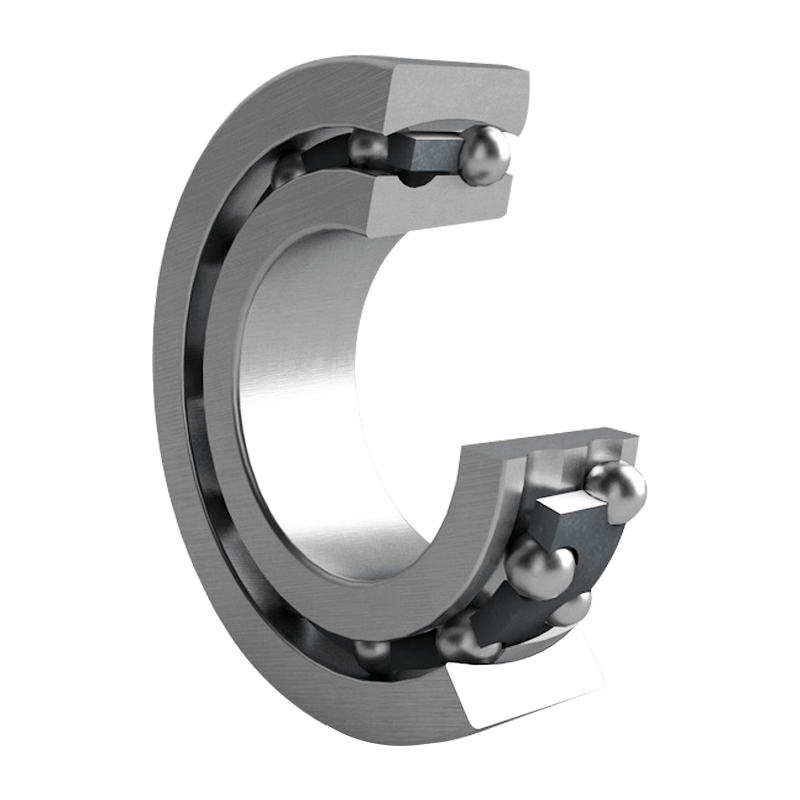

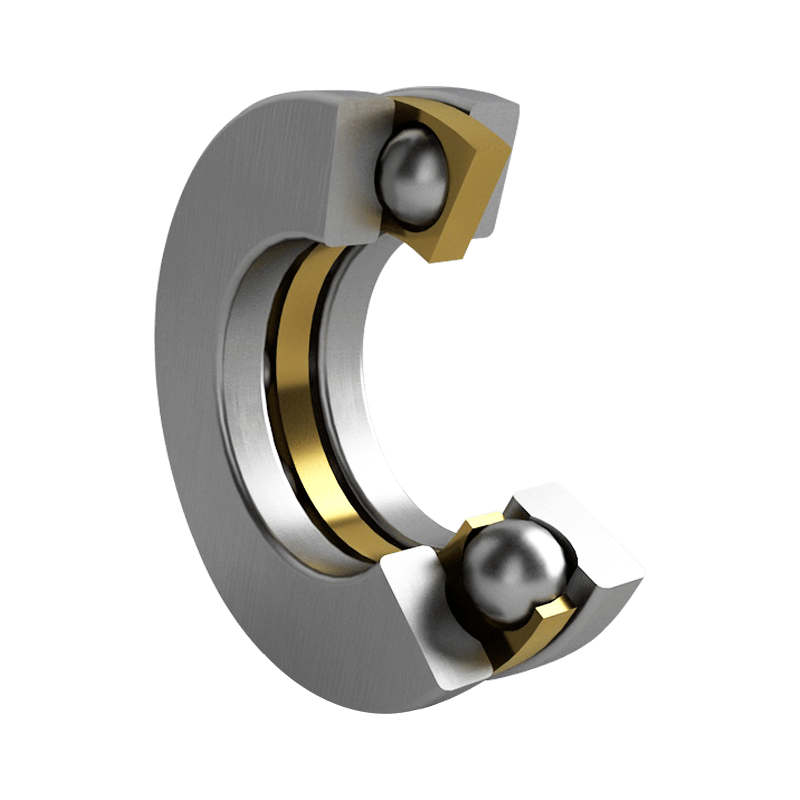

Deep Groove Ball Bearing

Learn More

The correct disassembly of deep groove ball bearings is as important as their installation. Improper disassembly methods may damage the bearings, shafts or lobes. Using the right tools and methods to ensure a safe and efficient disassembly process. Here are the disassembly methods and recommended tools for deep groove ball bearings.

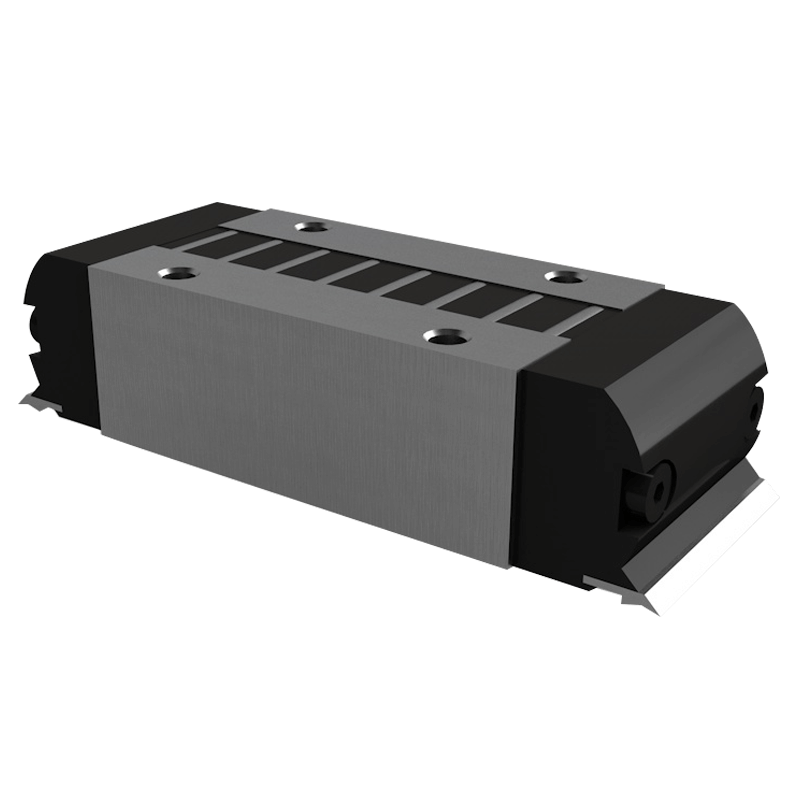

Reduce Load: Before disassembly to make sure the machine comes to a complete stop and release all load.

Clean the Work Area: Ensure that the disassembly area is clean to avoid contamination.

Loosen Gradually: If the bearing is held in place by fasteners, loosen those fasteners gradually.

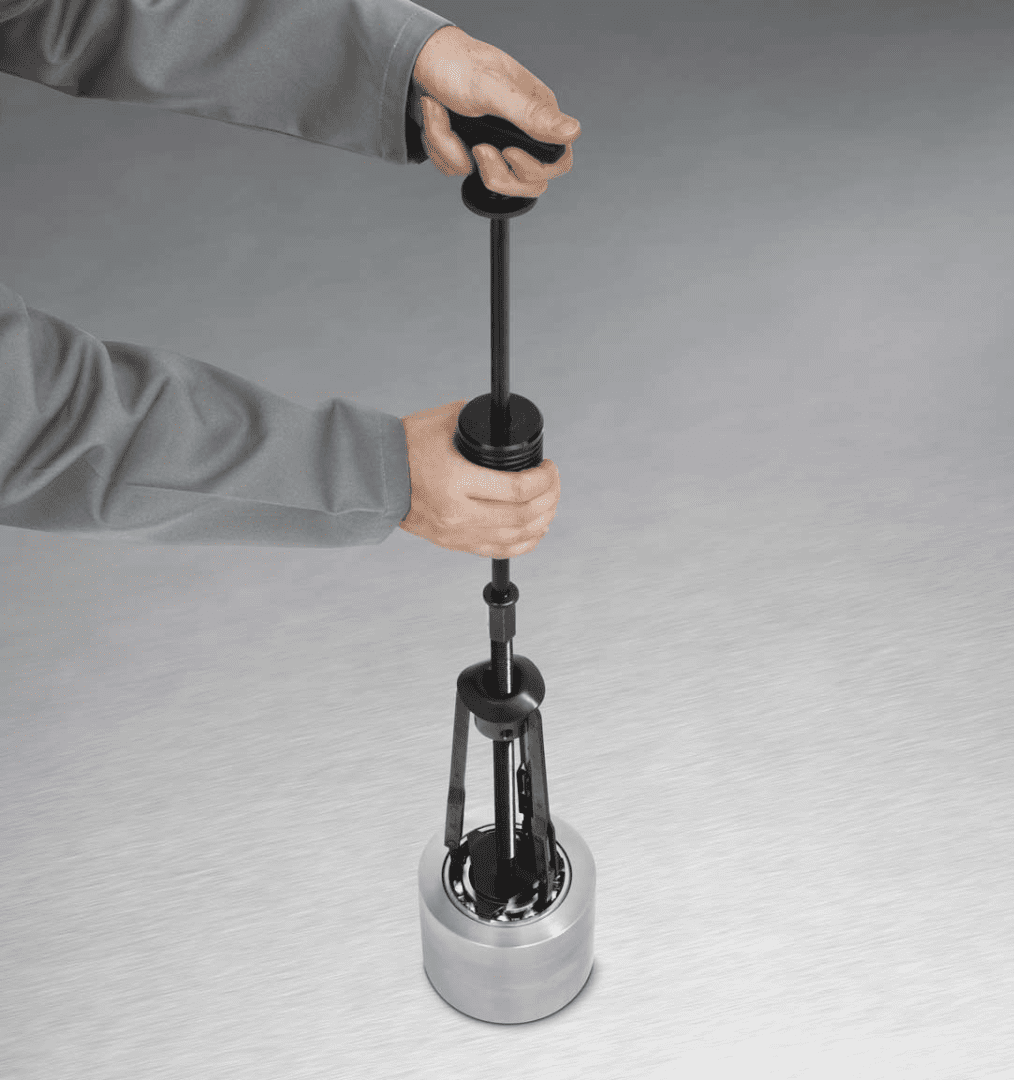

Apply Force Evenly: Use a puller or other removal tool to apply force evenly to avoid uneven stress on the bearing or shaft.

Heating: In some cases, gentle heating can help loosen bearings, but we need to control the temperature to avoid damaging bearings or other mechanical components.

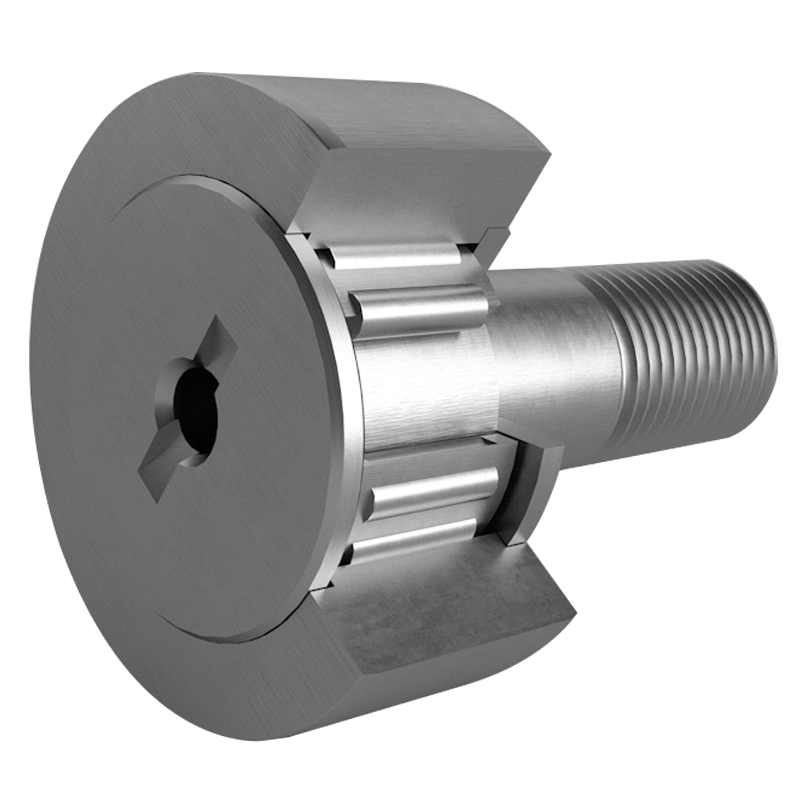

Inner Puller: It is used to remove the inner ring from the shaft.

Outer Puller: It is used to remove the outer ring, especially when the bearing is tight against the housing.

Hydraulic Tools: Using a hydraulic removal tool can provide greater force and control for tight or large bearings.

Heater: A dedicated bearing heater evenly heats the bearing to aid in loosening.

Hammer and Punch: Use hammer and punch if it is necessary. Careful operation to avoid damaging bearings or shafts.

Safety First: Ensure operational safety throughout the entire disassembly process.

Avoid Damage: Careful operation to prevent unnecessary damage to bearings, shafts or housings.

Record and Inspect: Record any abnormalities during disassembly and inspect bearings and related components for signs of damage or wear.

Proper disassembly of deep groove ball bearings requires appropriate tools and methods. Careful and focused operation not only protects the bearings, but also helps protect the integrity of the entire mechanism.

Proper disassembly not only protects the bearings, but also ensures the safety of the shaft and housing to prevent future mechanical failures. Always following the manufacturer's recommendations and standard operating procedures is key to ensuring a successful and safe disassembly.

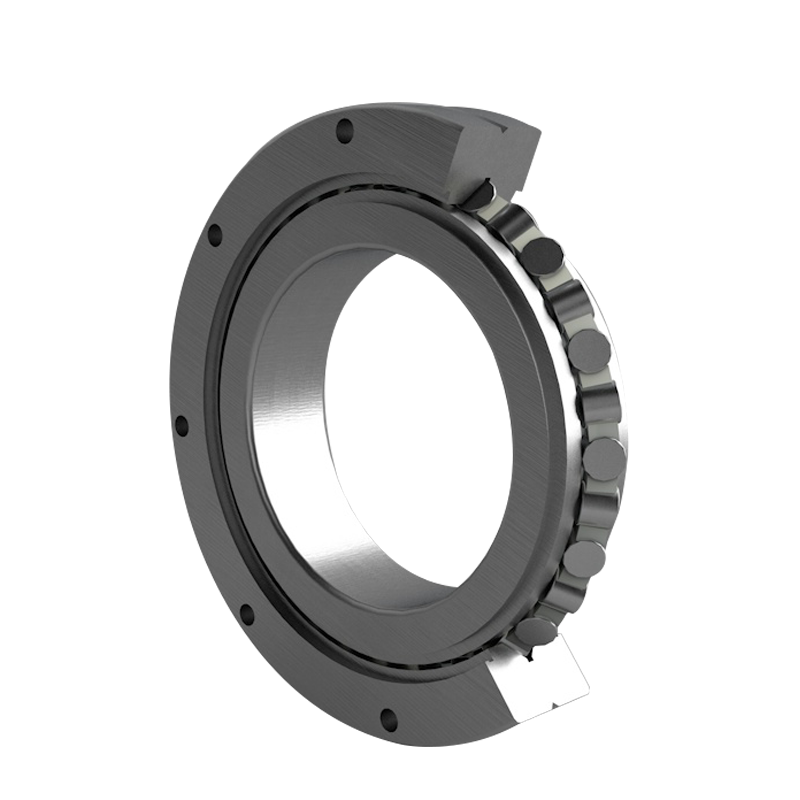

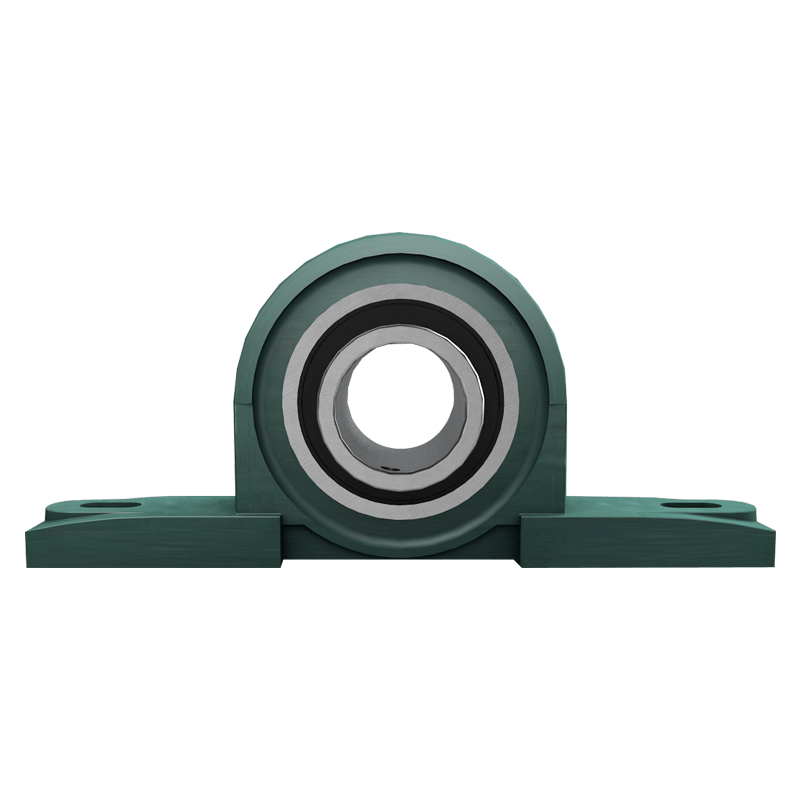

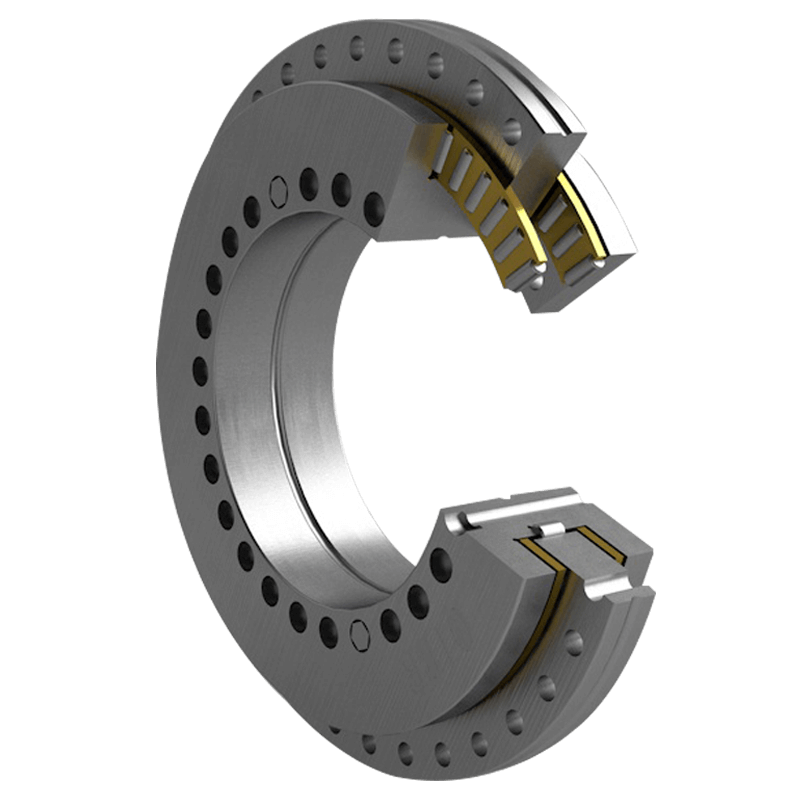

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation