WEBINAR

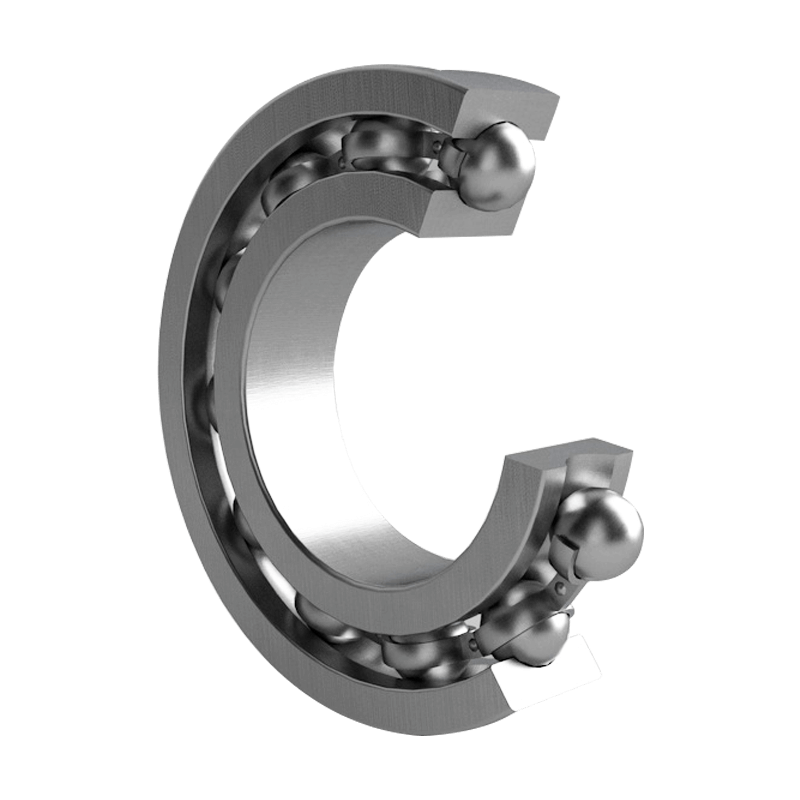

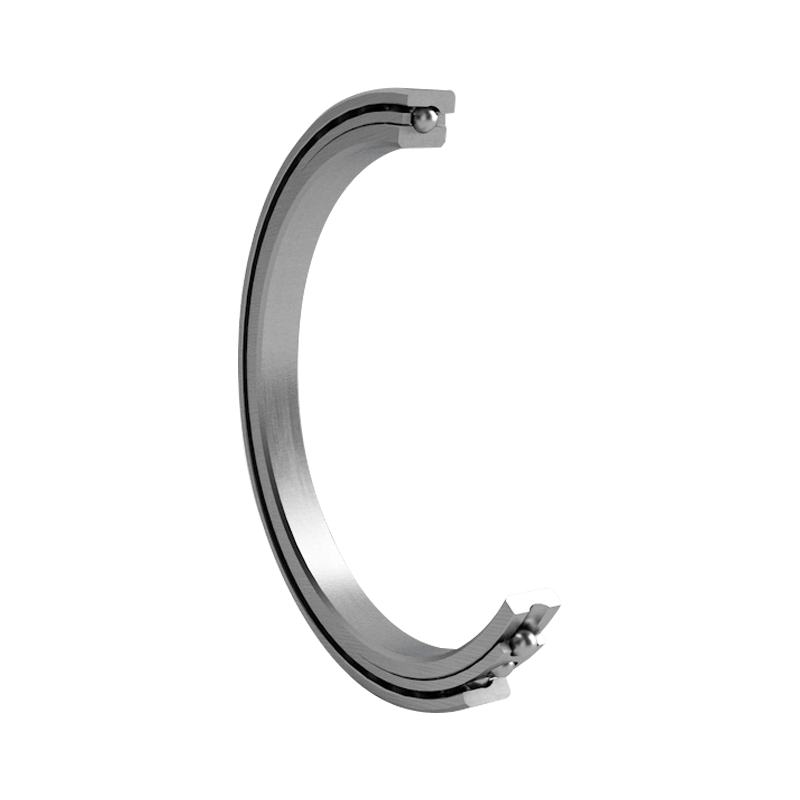

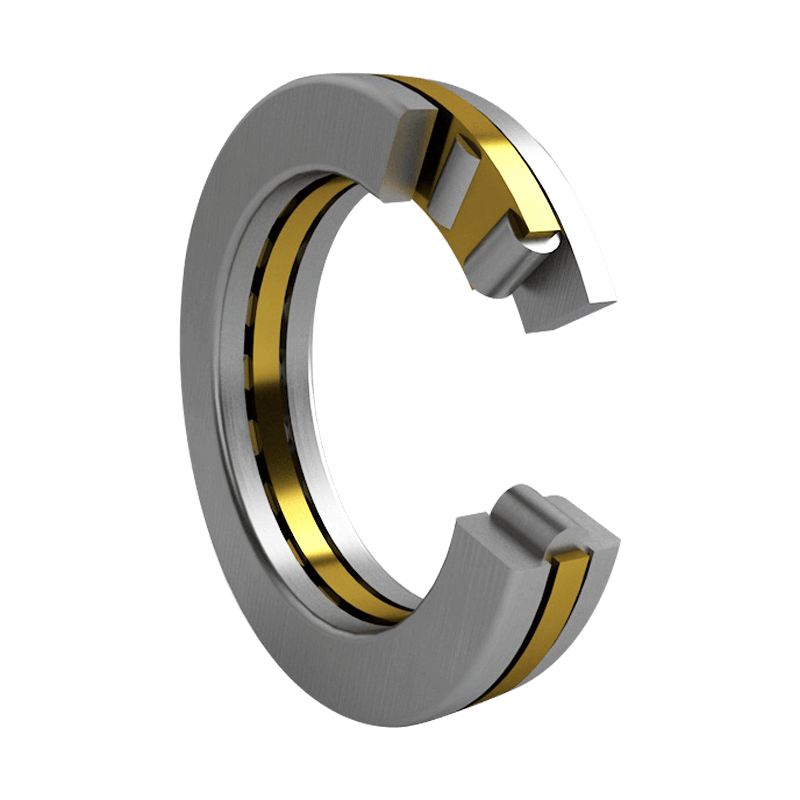

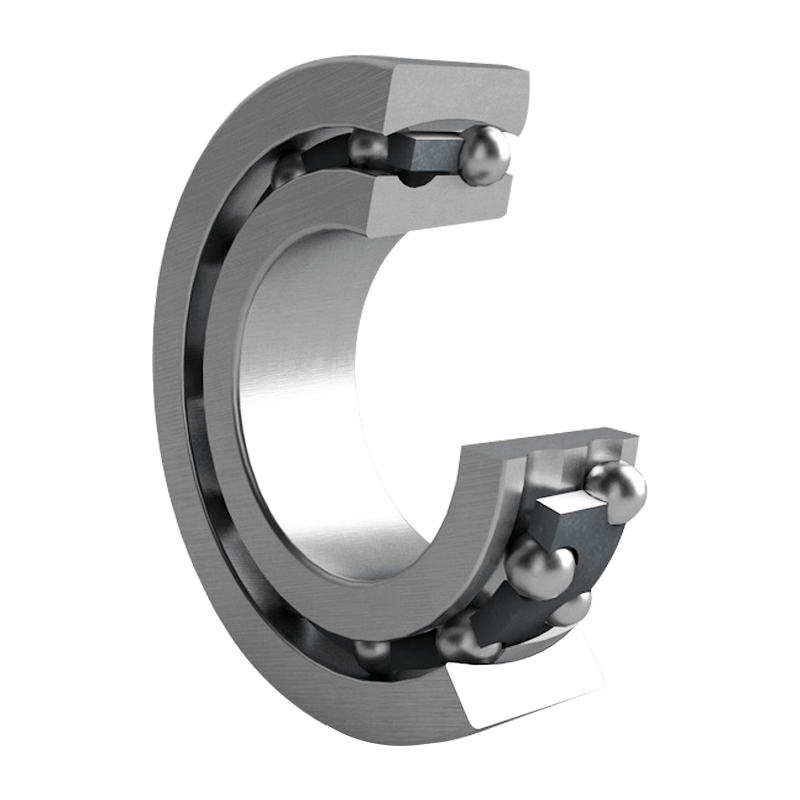

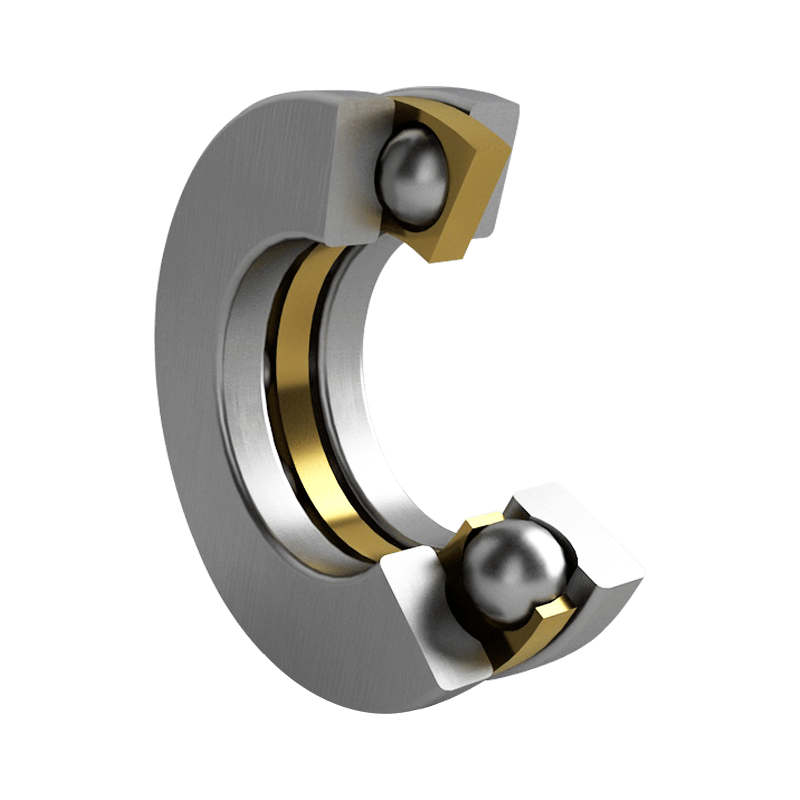

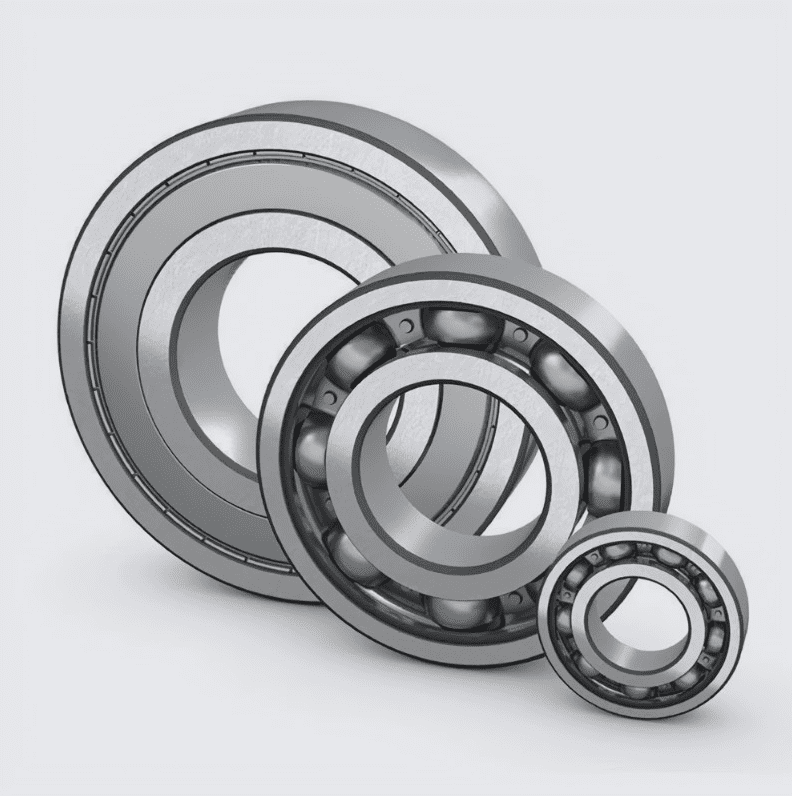

Deep Groove Ball Bearing

Learn More

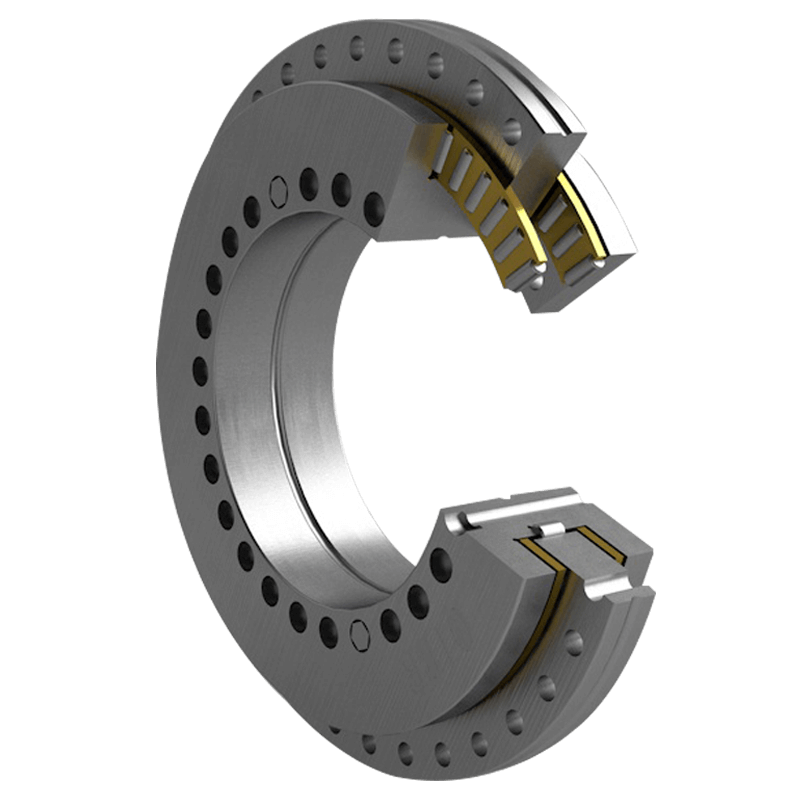

Dynamic load assessment is a critical step in determining bearing performance and life under actual operating conditions. For deep groove ball bearings, this involves understanding and calculating the varying loads the bearing is subjected to during operation. The following are the basic steps and considerations for conducting dynamic load assessment and calculations.

Dynamic load refers to the load actually carried by the bearing during operation, which is usually a changing value and may include radial load, axial load, or a combination of both.

The dynamic load capacity of a bearing is usually provided by the manufacturer and is given in the bearing's technical specifications.

The dynamic equivalent load P is a theoretically calculated load value that represents a constant radial load that has the same effect on the bearing life as an actual varying load. The calculation formula is :

P=X×Fr+Y×Fa

Fr is the actual radial load, Fa is the actual axial load, and X and Y are coefficients determined by the bearing type and load direction.

Load and Direction: Including radial load and axial load.

Bearing Life: Choosing the appropriate bearing based on the required life.

Operating Speed: High-speed operation may affect the thermal balance and lubrication conditions of the bearing.

Operating Temperature: High temperatures may affect material properties and lubricant selection.

Utilizing data sheets and calculation tools provided by the manufacturer can help make more precise calculations.

Use specialized software for simulations and more complex calculations, especially under variable loads and complex application conditions.

Accurately assessing and calculating dynamic loads on deep groove ball bearings is an important step in ensuring the appropriate bearing is selected and predicting its service life. This assessment can be made effectively using the correct formulas and data, taking into account actual operating conditions and load conditions.

When performing dynamic load calculations, it is strongly recommended to consult the bearing manufacturer's technical support or use specialized calculation tools to ensure the accuracy of the calculations and the suitability of the bearing.

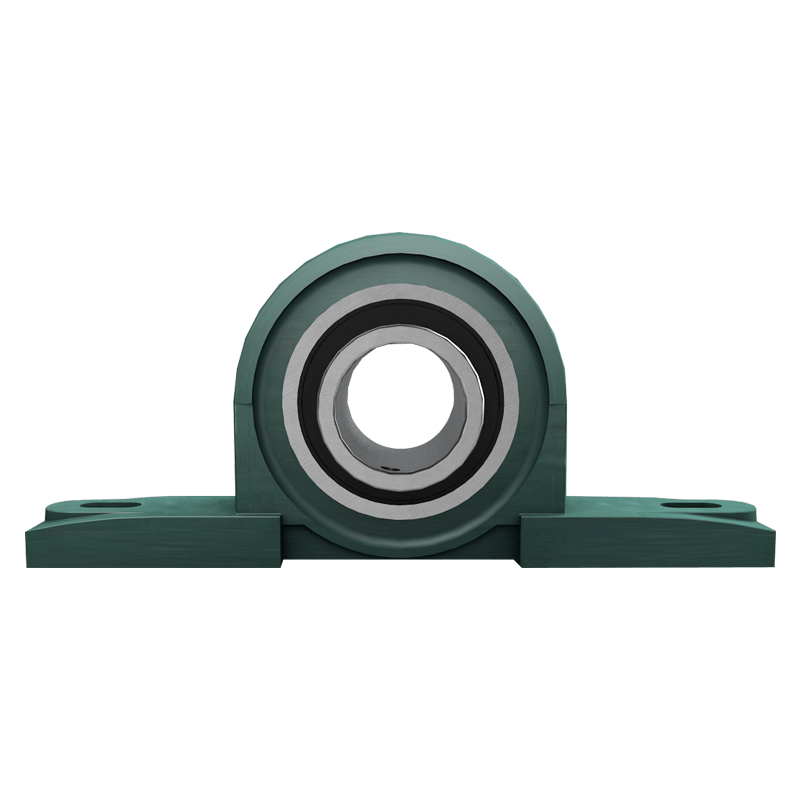

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation