WEBINAR

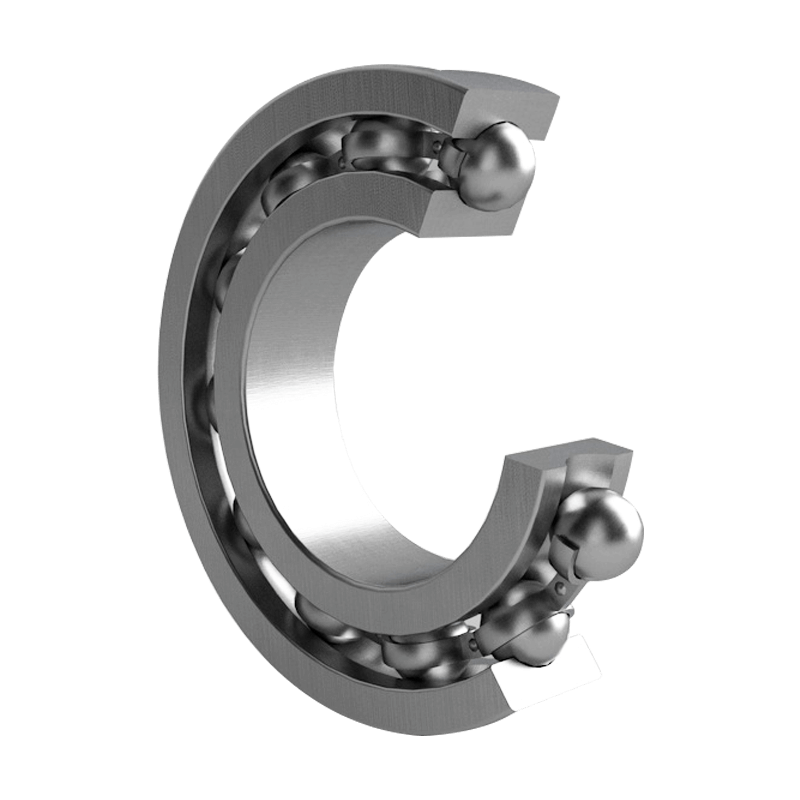

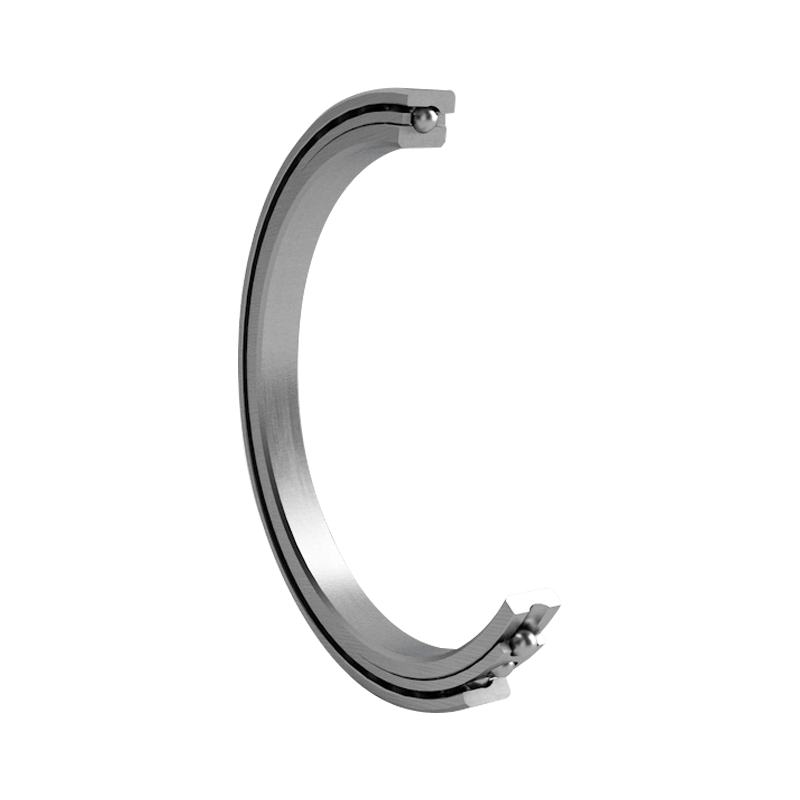

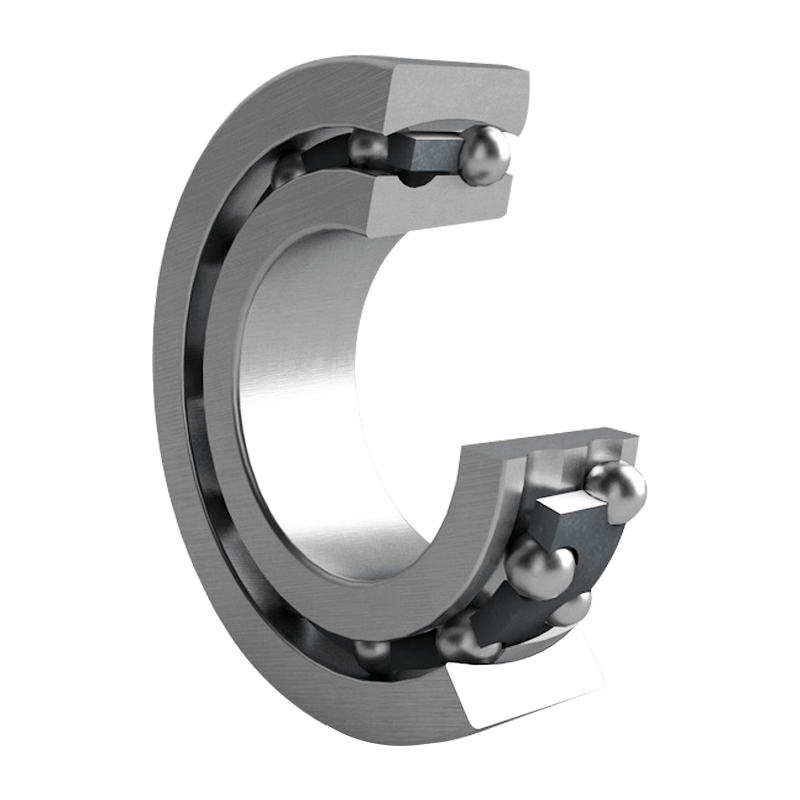

Deep Groove Ball Bearing

Learn More

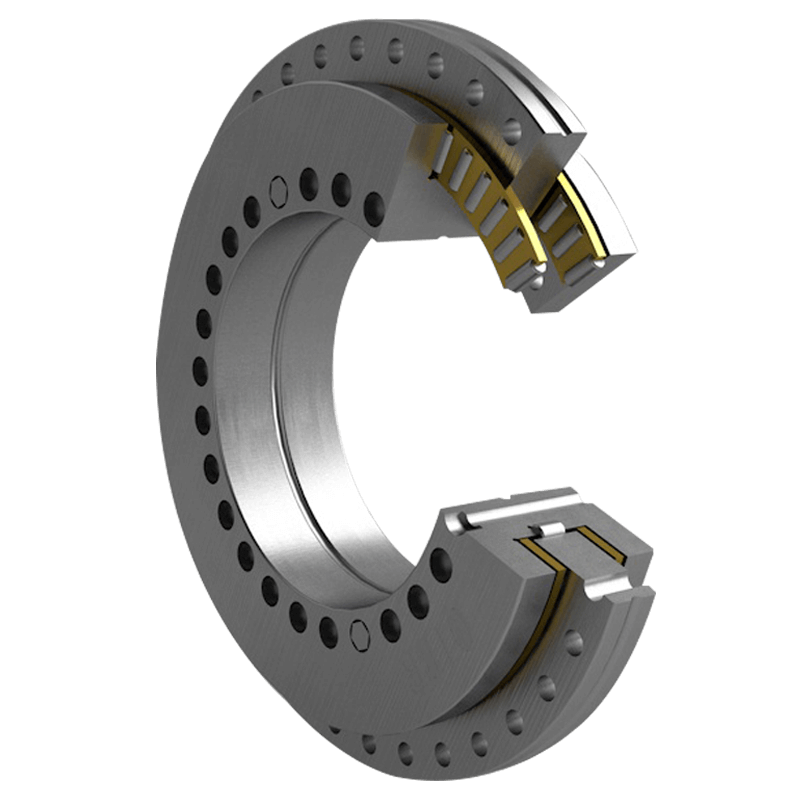

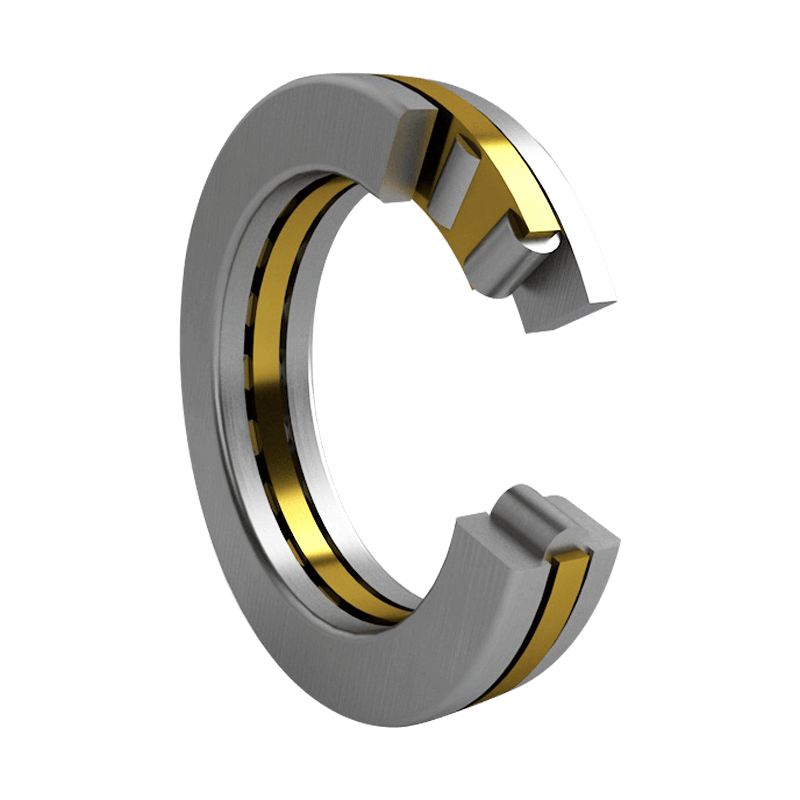

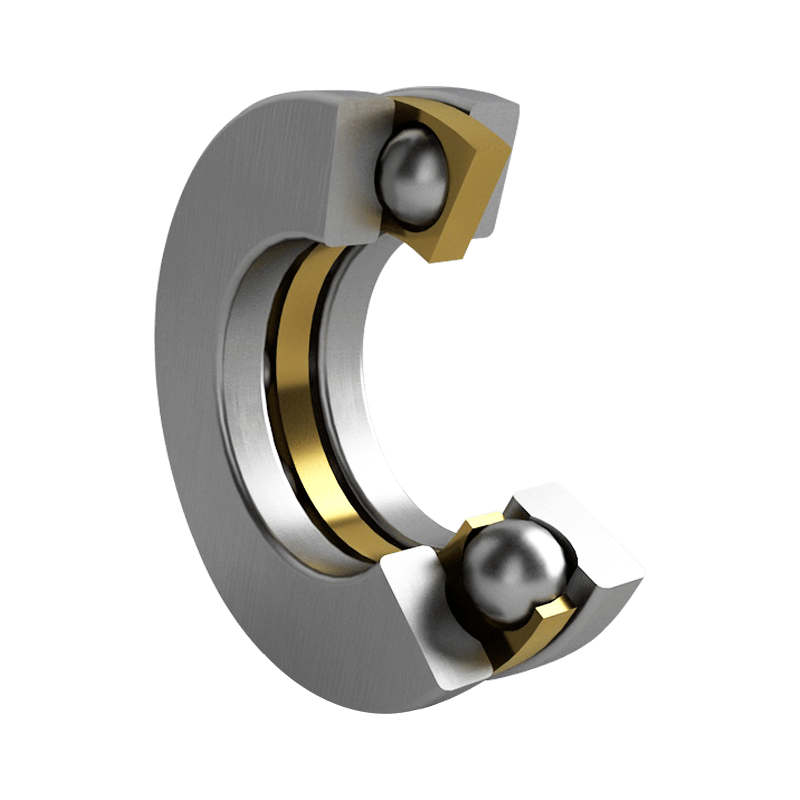

The heat treatment and surface treatment technology of thrust ball bearings are crucial to improving their hardness, wear resistance, fatigue strength and life.

The following is important information related to thrust ball bearing heat treatment and surface treatment technology:

Quenching: Quenching is a common heat treatment method that increases the hardness of bearing parts by heating them to a critical temperature and then cooling them rapidly. Quenching can be achieved by water, oil or air cooling, depending on the bearing material and design.

Tempering: Tempering is a step after quenching, aiming to reduce the brittleness of bearing parts and improve their strength and toughness. Tempering temperature and time vary based on specific bearing requirements.

Normalizing: Normalizing is a heat treatment method that improves the hardness and strength of bearing parts by heating them to an appropriate temperature and then cooling them naturally in the air.

Carburizing: Carburizing is a method of introducing carbon elements into the bearing surface to increase its hardness and wear resistance. This method is often used to increase the surface hardness of the bearing while still having sufficient toughness inside.

Grinding and Polishing: Surface grinding and polishing can be used to improve the surface accuracy and smoothness of bearings, reduce friction and improve performance.

Coating and Plating: The bearing surface can be coated or electroplated with various materials, such as nickel, chromium, zinc or ceramics to increase corrosion resistance, reduce friction, increase hardness and improve surface properties.

Magnetization: Some special applications may require magnetization of bearings to achieve specific functions, such as magnetic suspension bearings.

Superfinishing: Superfinishing can be used to further improve the smoothness and accuracy of bearing surfaces, reduce friction and improve performance.

The choice of these heat treatment and surface treatment technologies depends on the specific application, materials and design requirements of the bearing. Manufacturers often select the appropriate treatment method based on specific bearing specifications and performance needs. Proper heat treatment and surface treatment can significantly improve the performance, life and reliability of thrust ball bearings.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation