WEBINAR

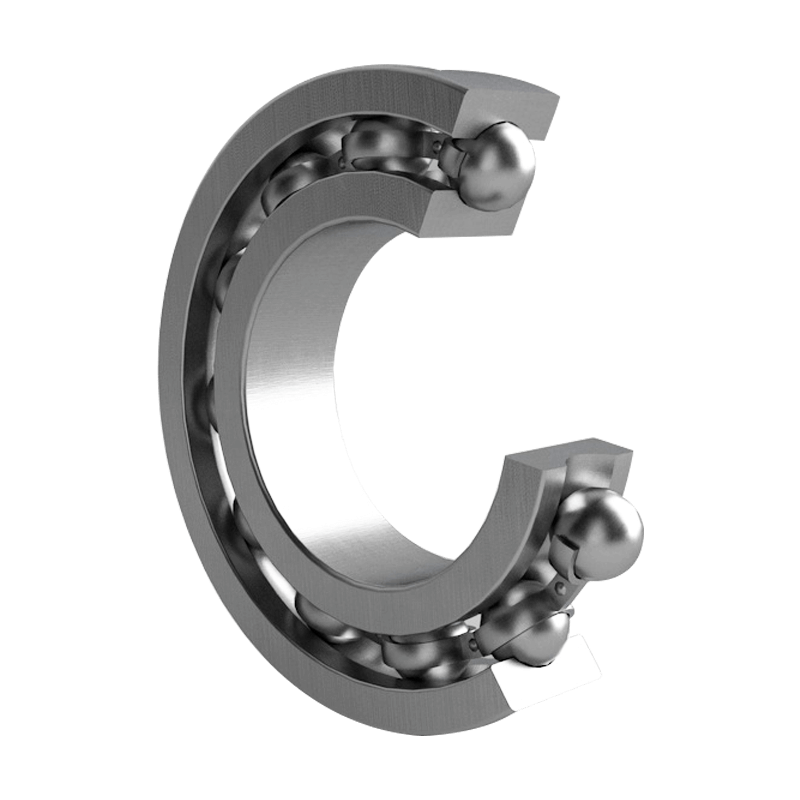

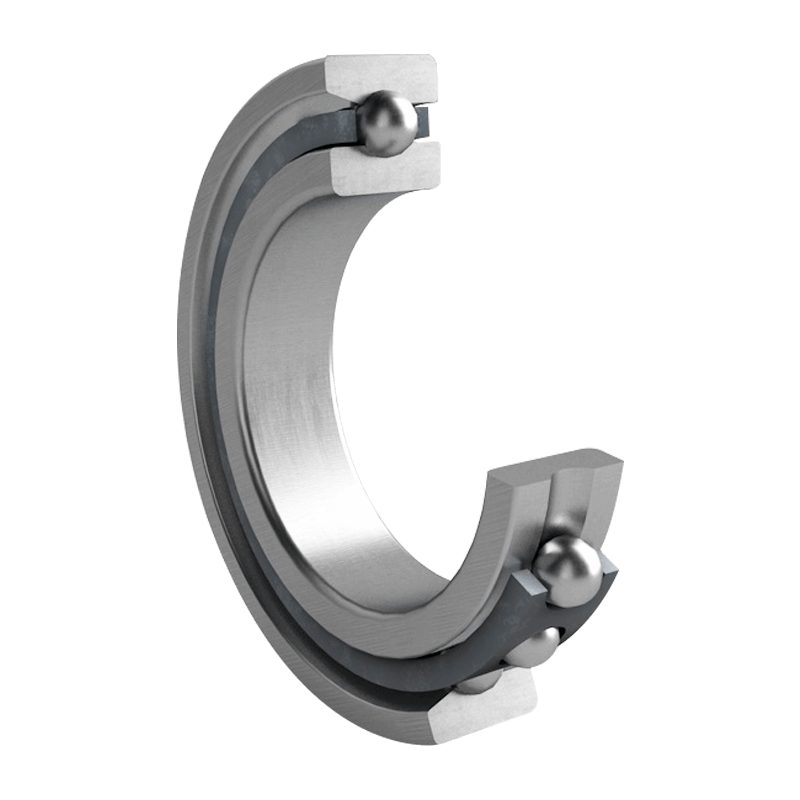

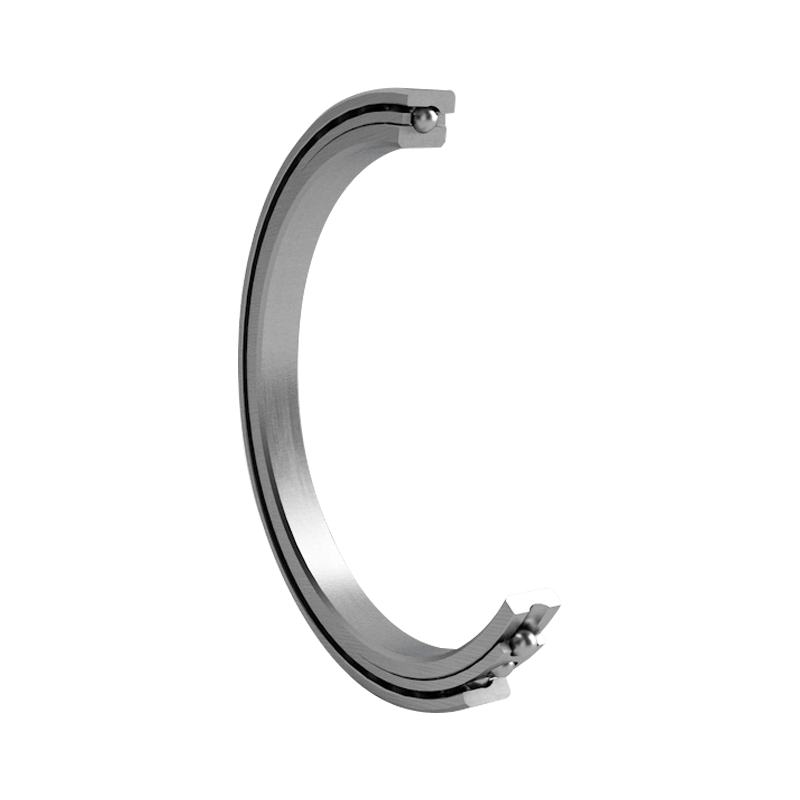

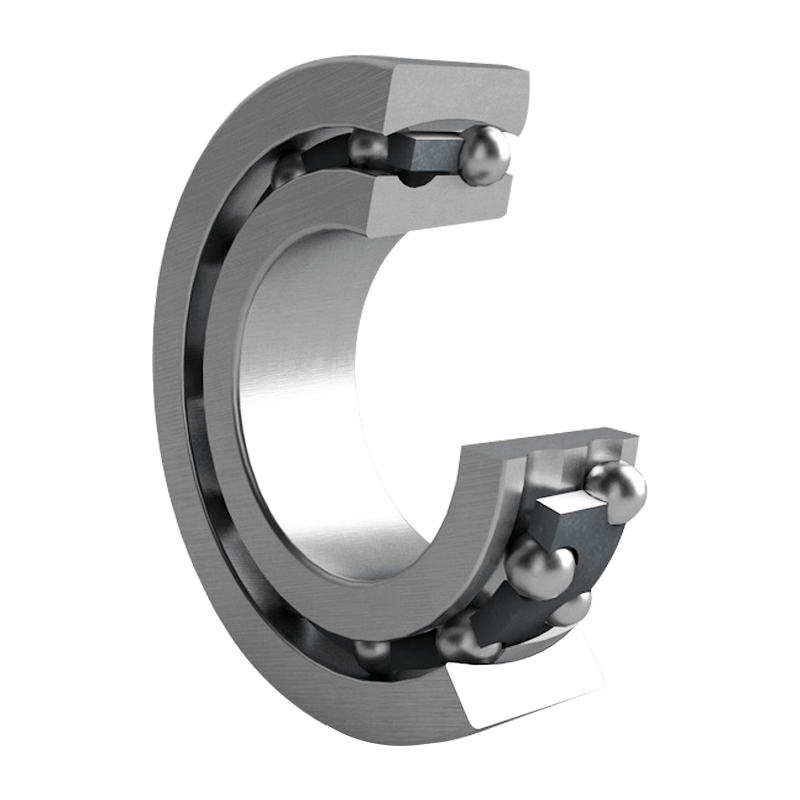

Deep Groove Ball Bearing

Learn More

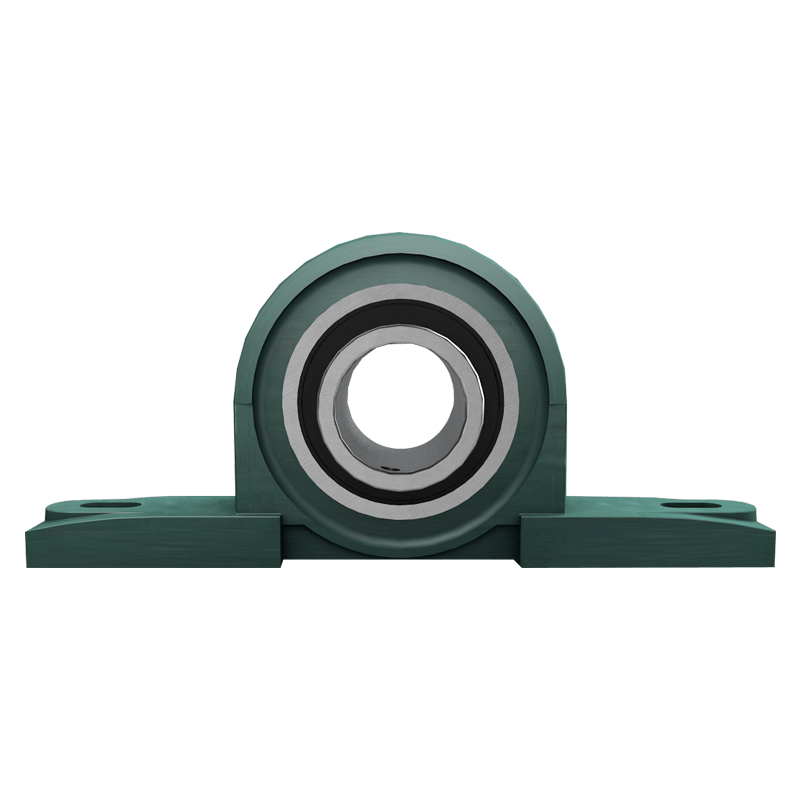

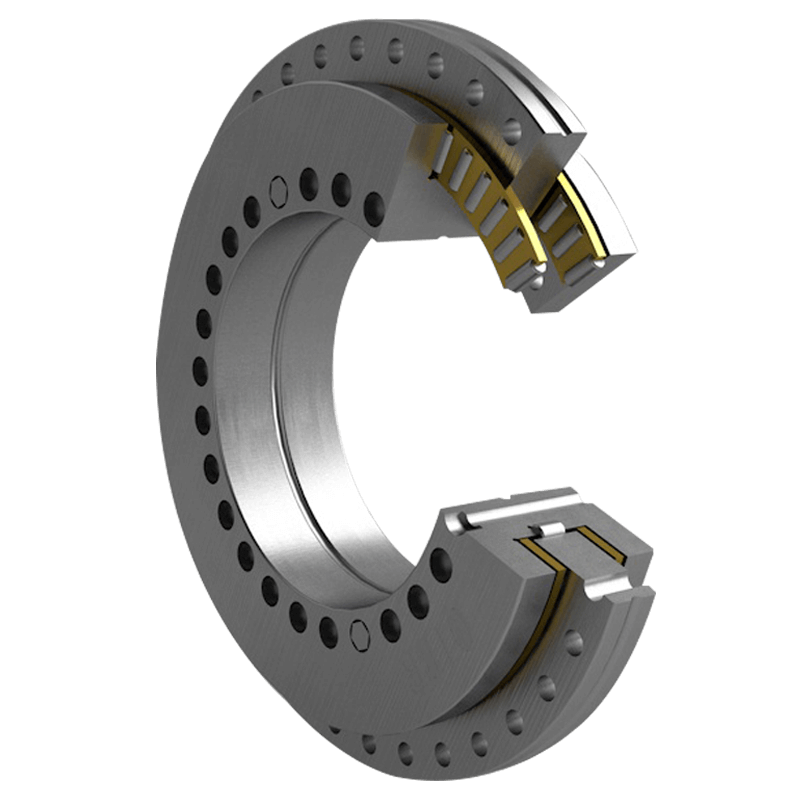

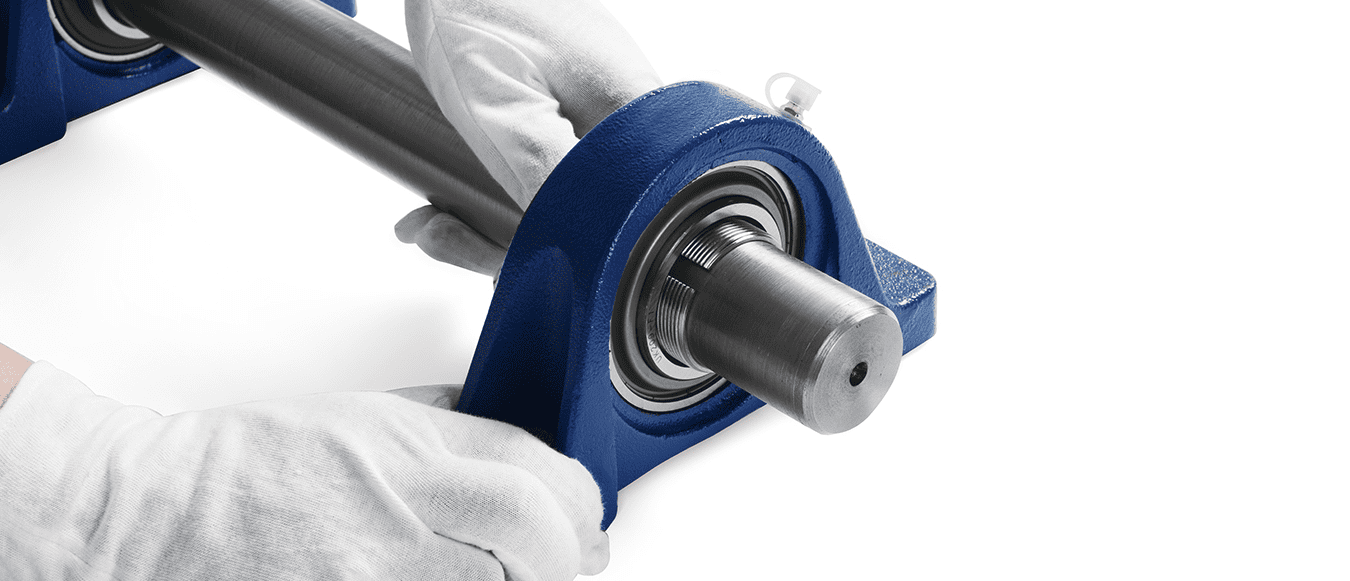

The correct installation of deep groove ball bearings is essential to ensure their performance and extend their service life. Improper installation can cause bearing damage, increasing wear, or even mechanical failure. The following are the technical points and matters needing attention when installing deep groove ball bearings.

Cleaning: Before installation, ensure that bearings and bearing seats and related components are clean and free of contamination.

Check the Mating Surfaces: Check the size and shape of the shaft and housing to ensure a proper fit.

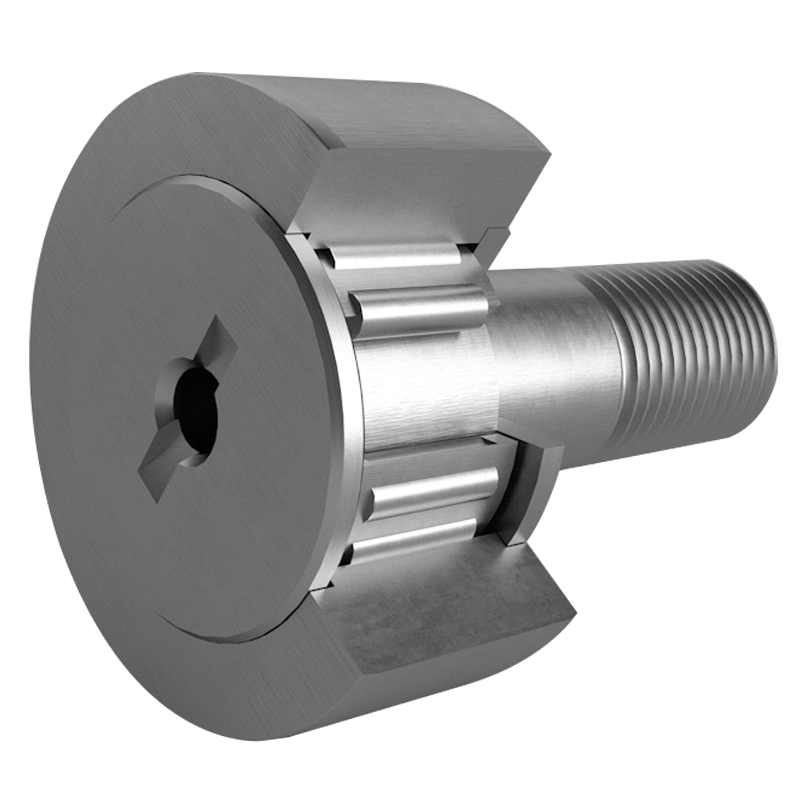

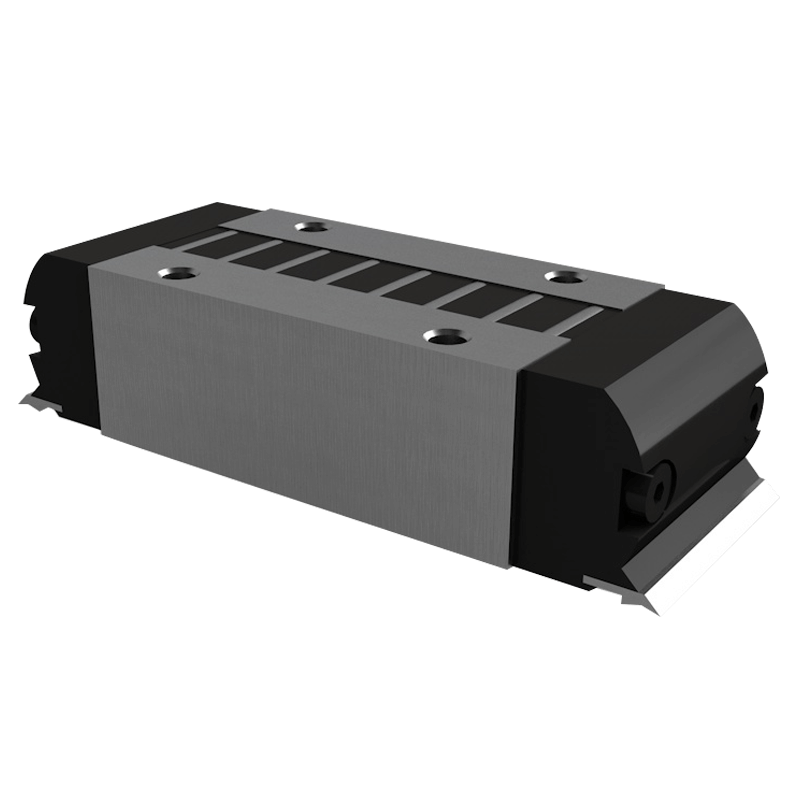

Correct Installation Tools: Use special tools such as bearing installation sleeves and avoid using hammers and other tools that may cause damage.

Uniform Force Application: During the installation process, the force should be applied evenly to avoid excessive local stress.

Heated Bearings: The inner ring of a bearing can be enlarged by heating it to make installation easier when necessary. Use special heating equipment to avoid exceeding specified temperatures.

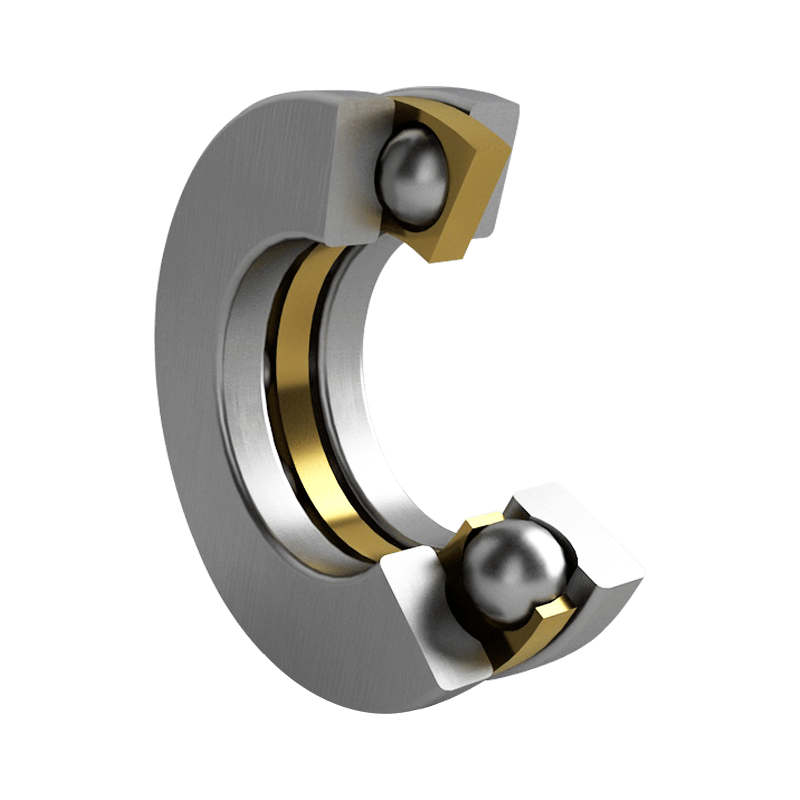

Bearing Preload: Adjust bearing preload according to design and application requirements.

Avoid Contamination: Even tiny contaminants can cause bearing damage.

Prevent Damage: Avoid damage to the rolling elements or raceways of the bearing during installation.

Installation Direction: Make sure the bearing is installed in the correct direction.

Lubrication: Make sure the bearings are properly lubricated (skip this step if pre-lubricated bearings before installation.

Check Rotation: Check whether the bearing rotates smoothly and without resistance after installation.

Record and Mark: Record the installation process and date, and mark if necessary for future maintenance.

Proper installation method is critical to the performance and life of deep groove ball bearings. Following proper installation procedures and precautions can avoid many common problems and ensure that bearings maintain optimal performance throughout their service life.

The installation of deep groove ball bearings is a delicate process that requires technical knowledge and appropriate tools. The key to successful installation is remaining meticulous and focusing on the entire process .

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation