WEBINAR

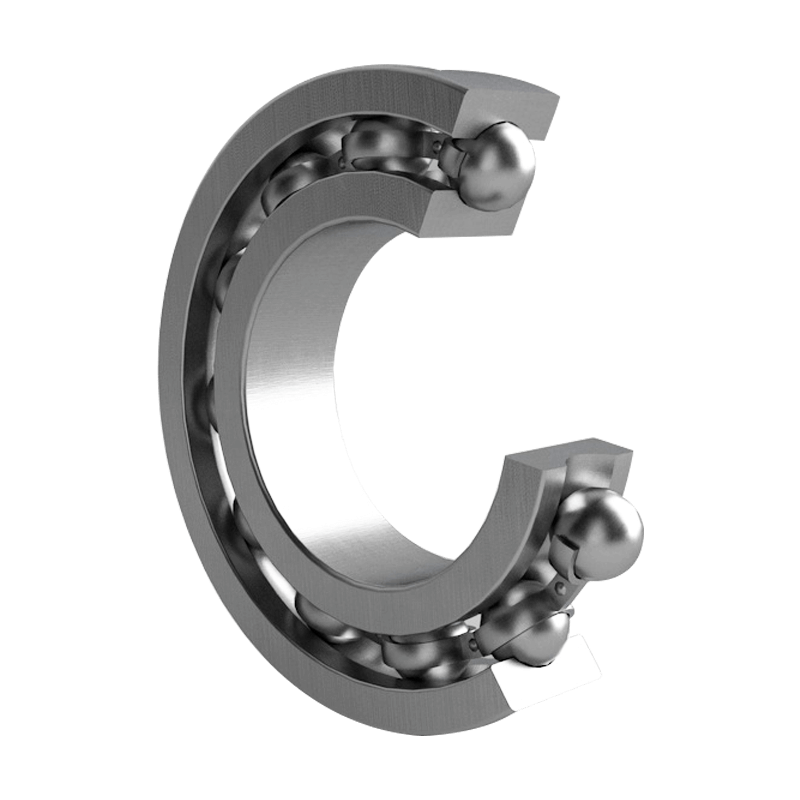

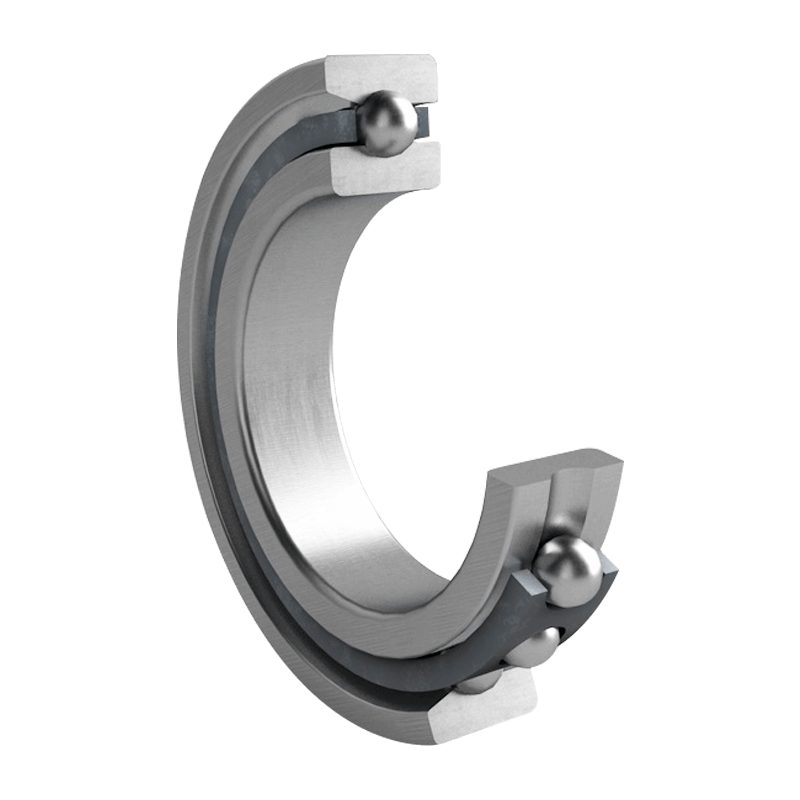

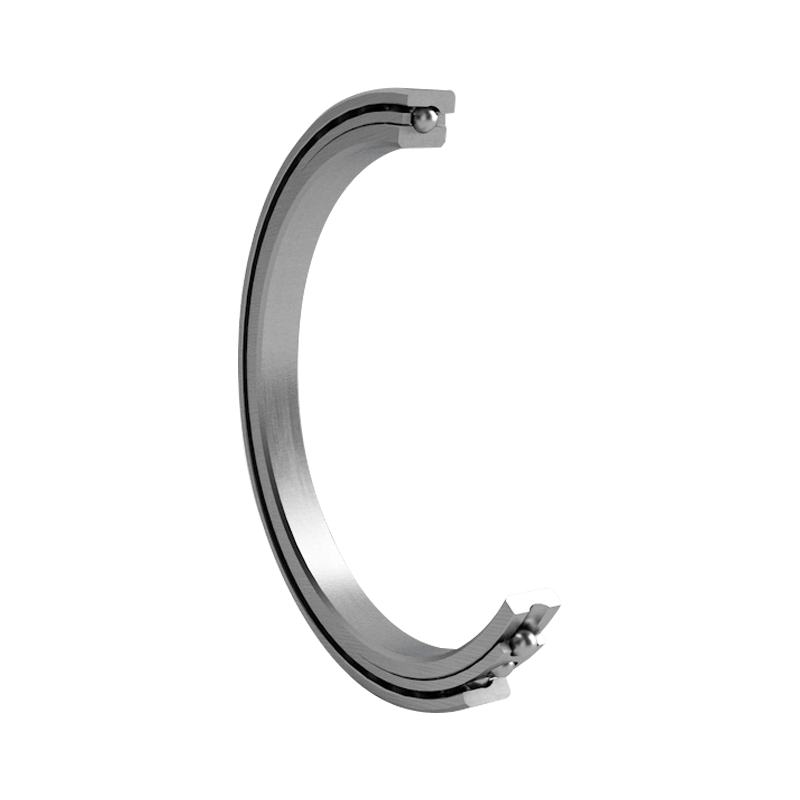

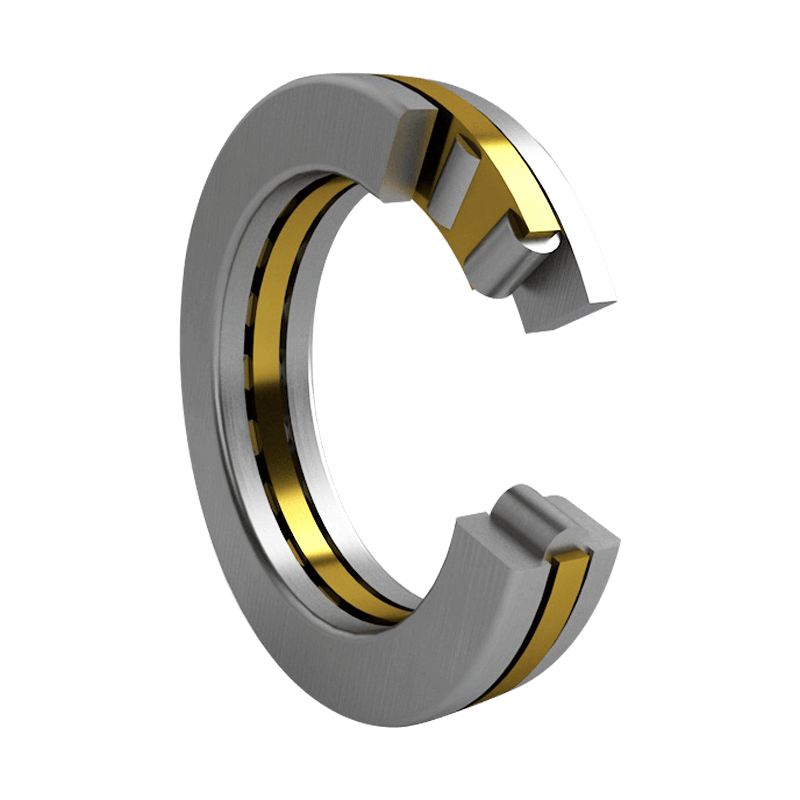

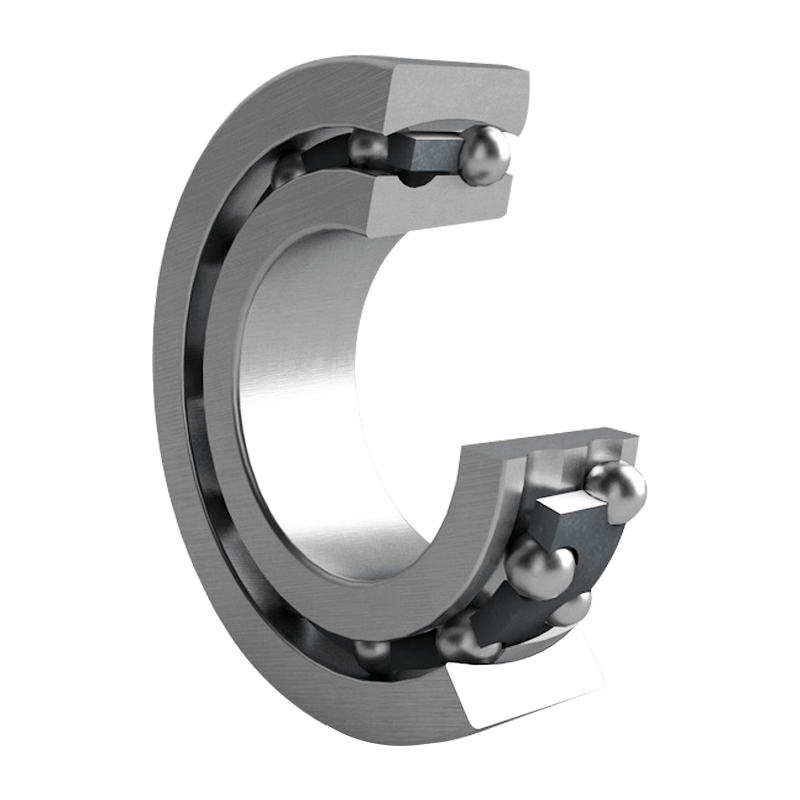

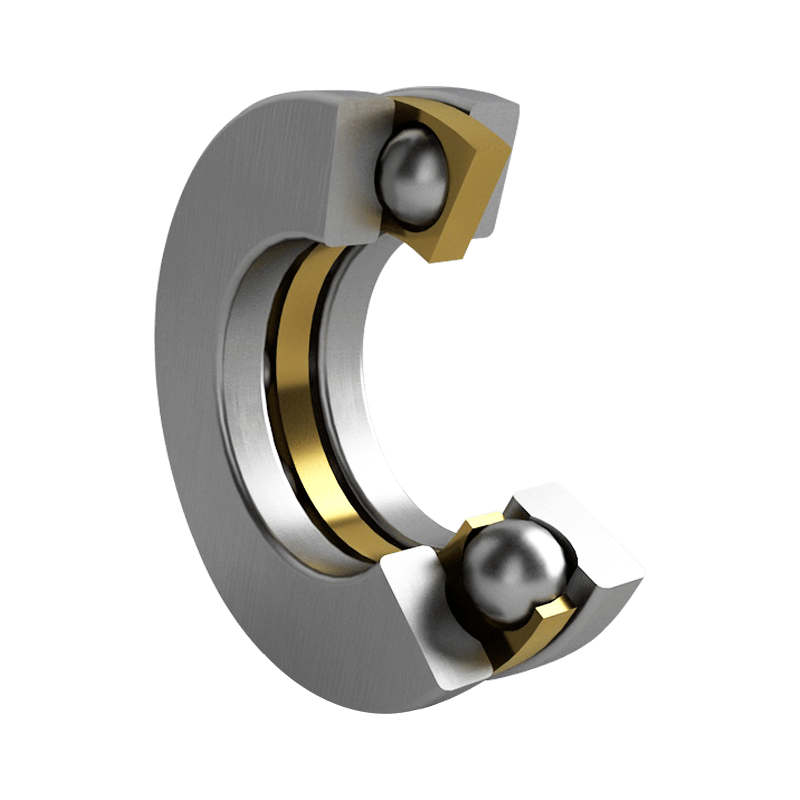

Deep Groove Ball Bearing

Learn More

Deep groove ball bearings are critical components in mechanical equipment, and their performance and life depend largely on proper maintenance and upkeep. Regular maintenance can not only extend the service life of bearings, but also improve the reliability and efficiency of mechanical equipment. Here are some maintenance strategies and care tips.

Periodic Inspections: Perform visual and auditory inspections of bearings regularly , looking for signs of unusual noise, vibration, or elevated temperatures.

Cleaning: Keep the bearing and surrounding environment clean to prevent contaminants from invading the inside of the bearing.

Lubrication: Check and replace lubricant regularly. Make sure to use a lubricant suitable for the bearing and application environment.

Anti-corrosion: Use appropriate protective measures in corrosive environments, such as using anti-corrosion lubricants or seals.

Choose the Right Lubricant: Choose the right grease or oil lubricant based on the bearing type and operating conditions.

Proper Lubrication: Avoid excessive or insufficient lubrication. Over lubrication can lead to overheating, while insufficient lubrication can lead to increased wear.

Use the Correct Tools: Use the correct tools during installation and maintenance to prevent unnecessary force or damage to the bearings.

Storage: Store unused bearings in a dry, clean, and temperature-friendly environment to avoid direct exposure to the external environment.

Temperature Monitoring: Monitor the operating temperature of the bearings. High temperatures may be a sign of poor lubrication or overloading.

Record Maintenance History: Record the time and activity of each maintenance and replacement to track bearing condition and predict future maintenance needs.

Effective maintenance and care of deep groove ball bearings are essential to ensure the efficient operation of mechanical equipment. By implementing proper maintenance strategies and care techniques, which can significantly improve the bearing performance and service life.

Proper maintenance not only helps prevent bearing failure, but also reduces machine downtime and improves overall operational efficiency. Therefore, paying attention to the daily maintenance and regular inspection of bearings is a key part of the management of any high-performance mechanical system.

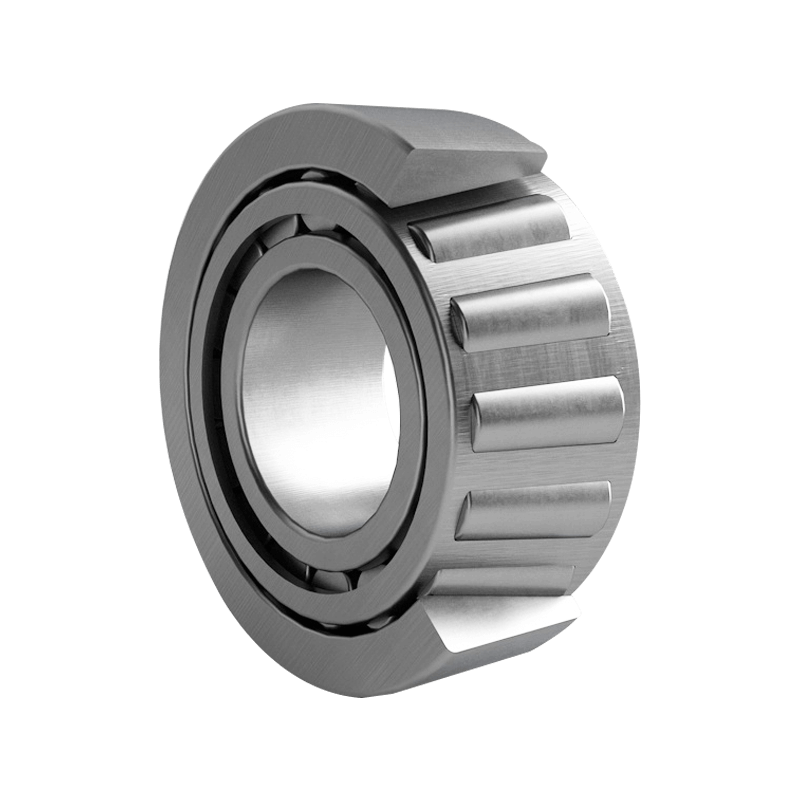

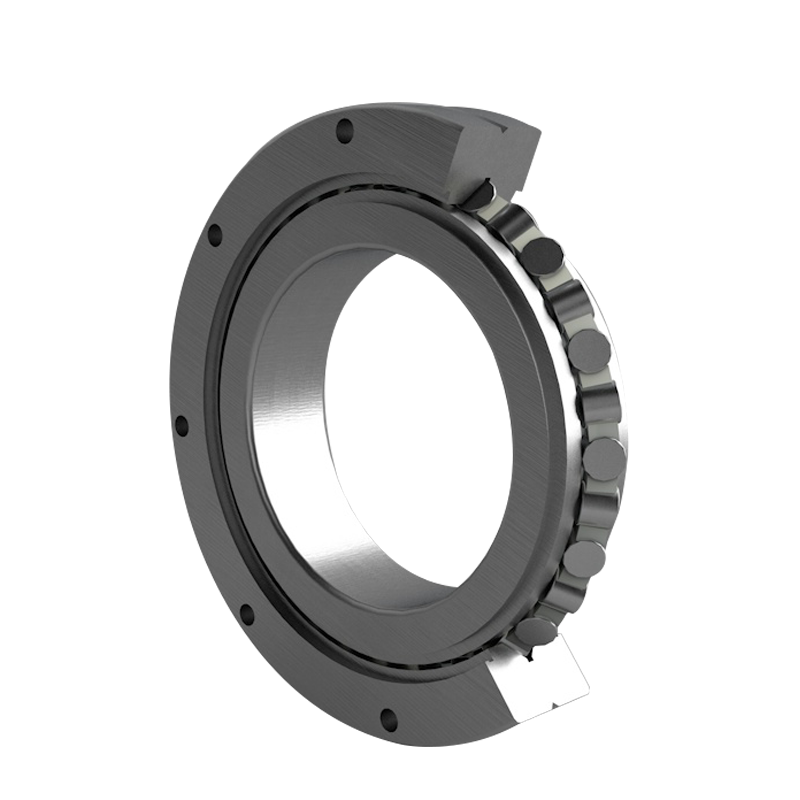

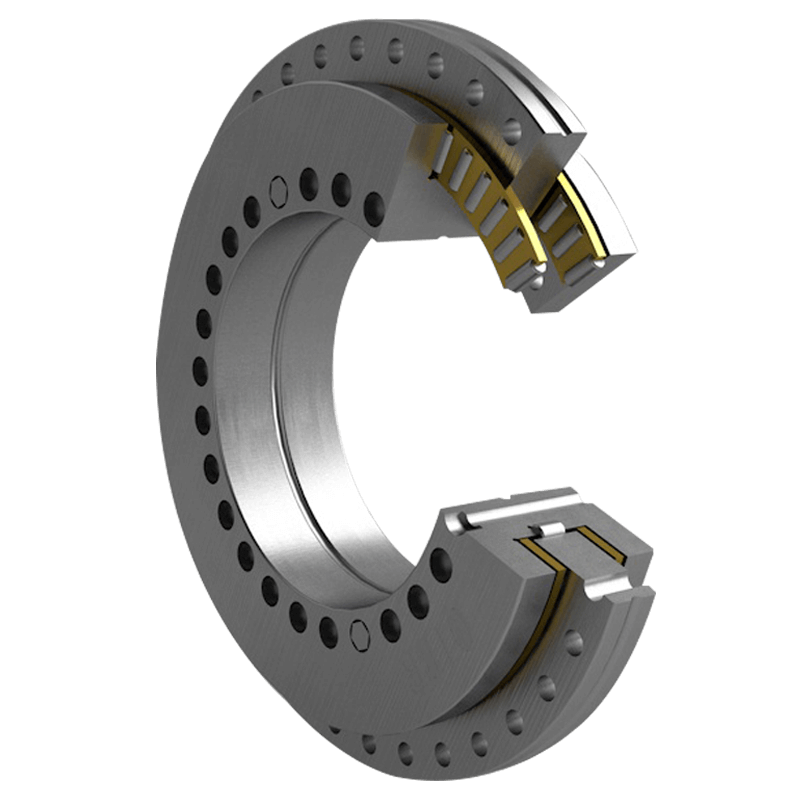

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation