WEBINAR

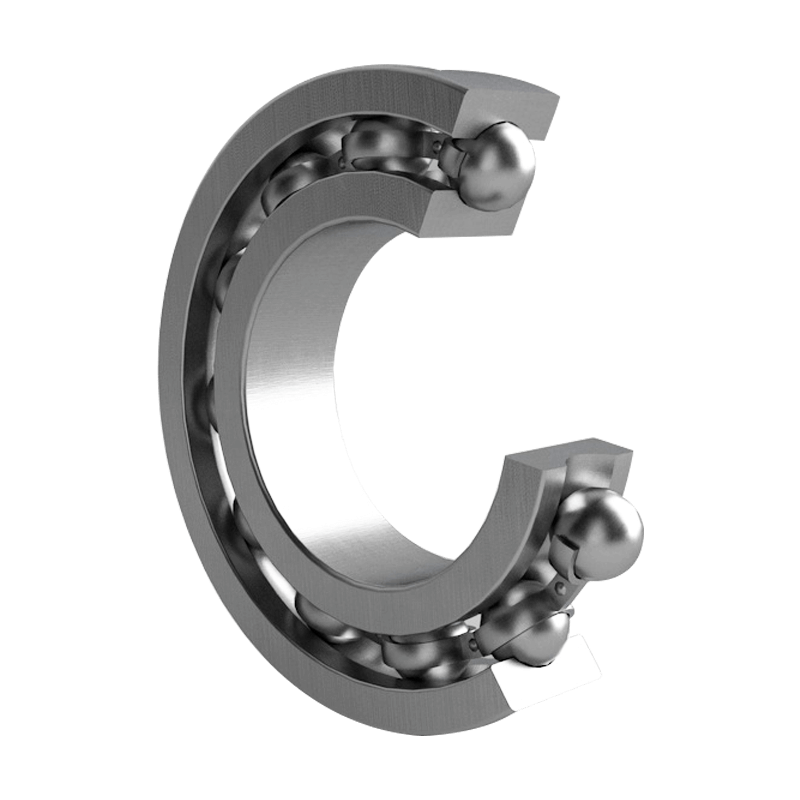

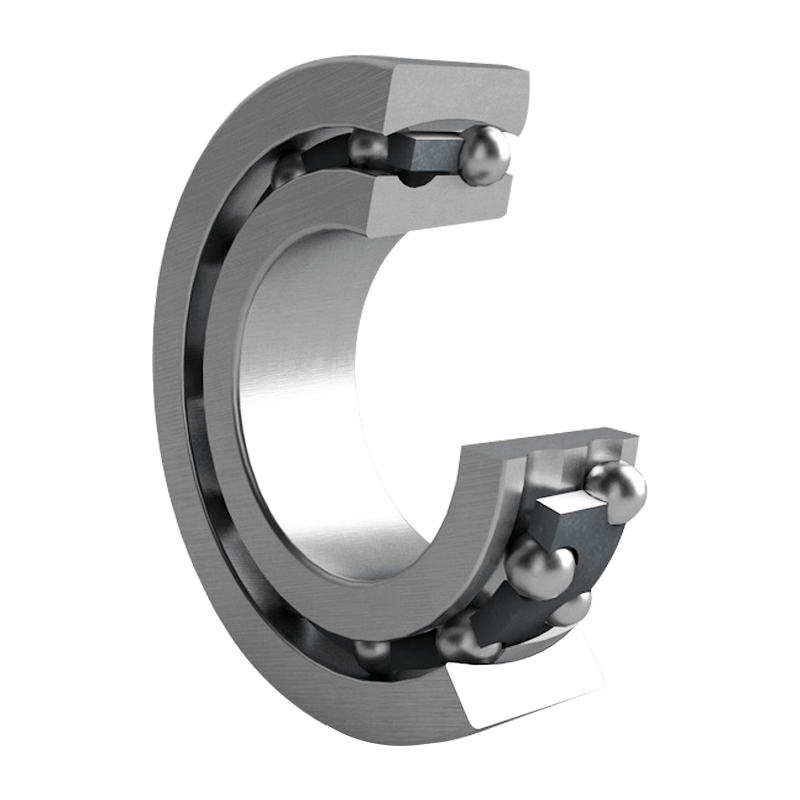

Deep Groove Ball Bearing

Learn More

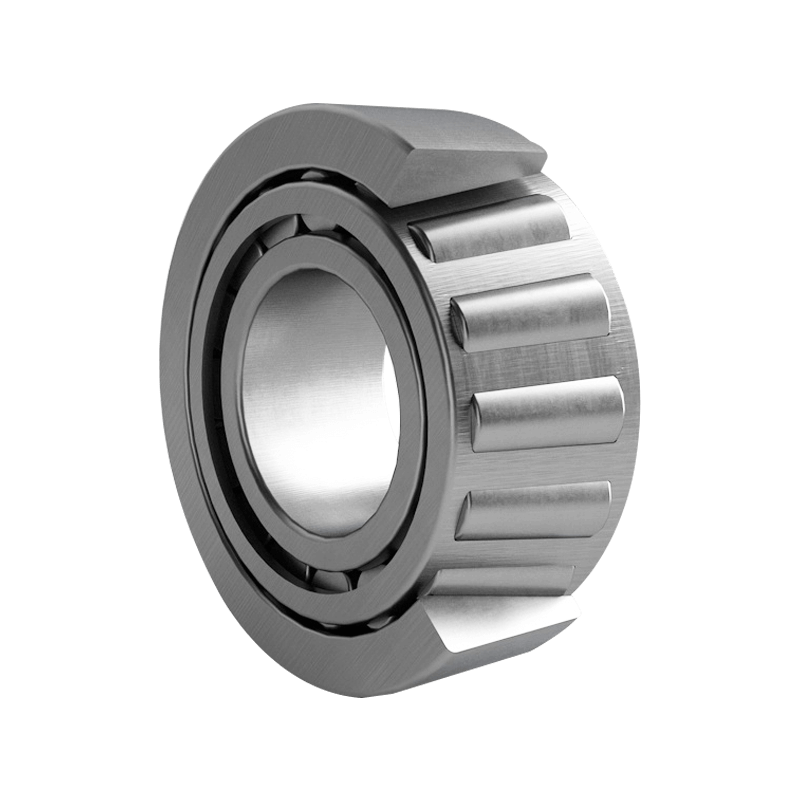

Needle roller bearings play an important role in the machine tool industry. Machine tools usually require bearings with high precision, high speed and high load capacity to ensure their precise processing and stable operation.

The following are some of the main areas of application of needle roller bearings in the machine tool industry:

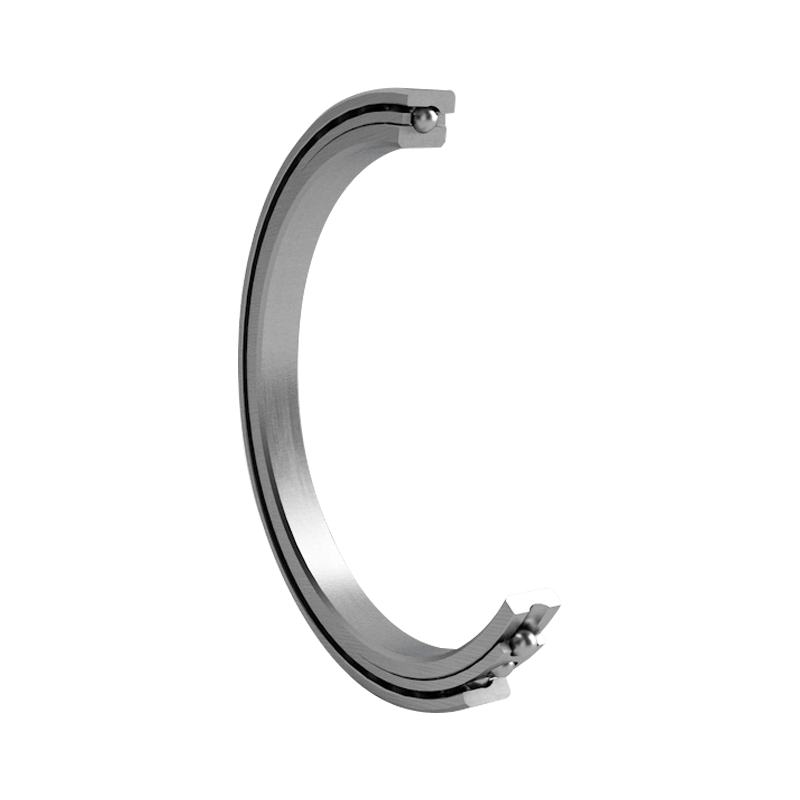

Main Bearing: The main shaft of machine tools usually uses high-speed needle roller bearings to support the rotation of the main shaft. These bearings have high rigidity and high precision, ensuring that the workpiece can maintain stable cutting quality when rotating at high speeds.

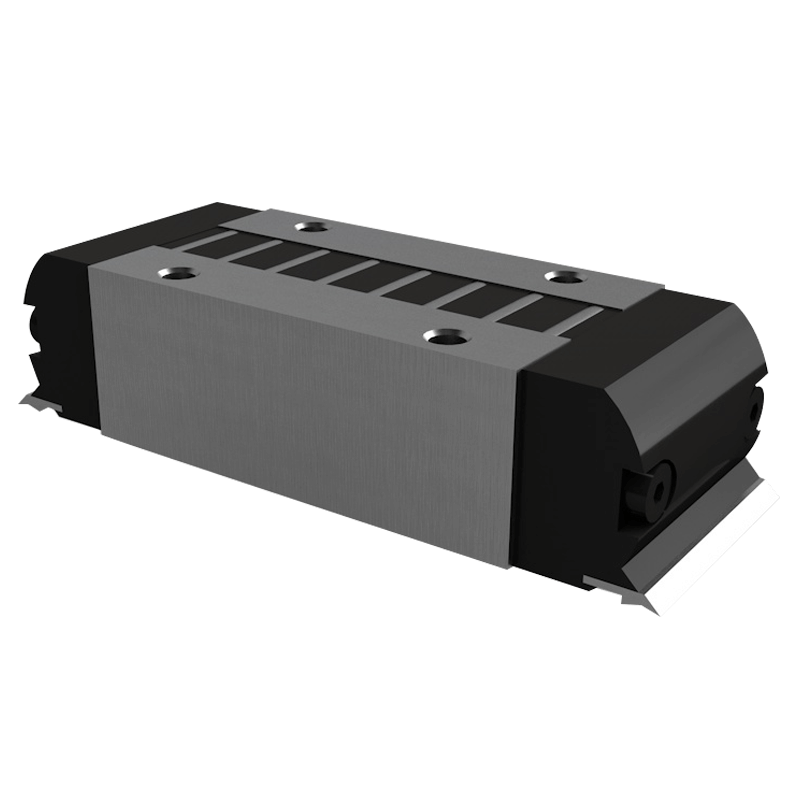

Sliding Guide Rail: The sliding guide rail system of machine tools usually uses needle roller bearing units to ensure smooth movement and high-precision positioning of the table or tool holder. These bearing units usually consist of multiple needle roller bearings to handle complex loads.

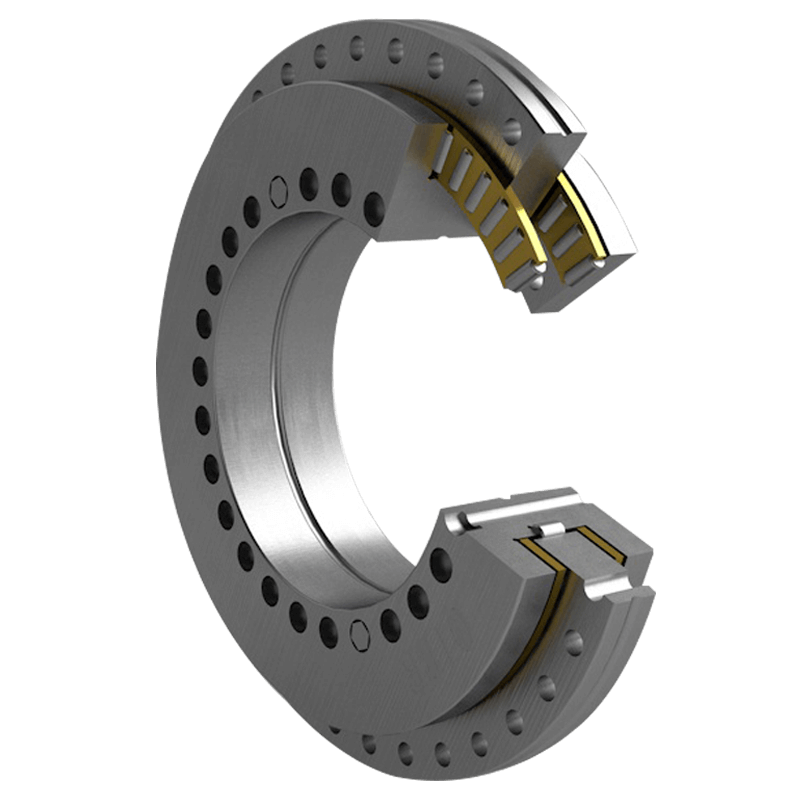

Ball Screw: Needle roller bearings are also commonly used in ball screw systems of machine tools to achieve precise position control of worktables or tool racks. These bearings provide high-precision and rigid linear motion.

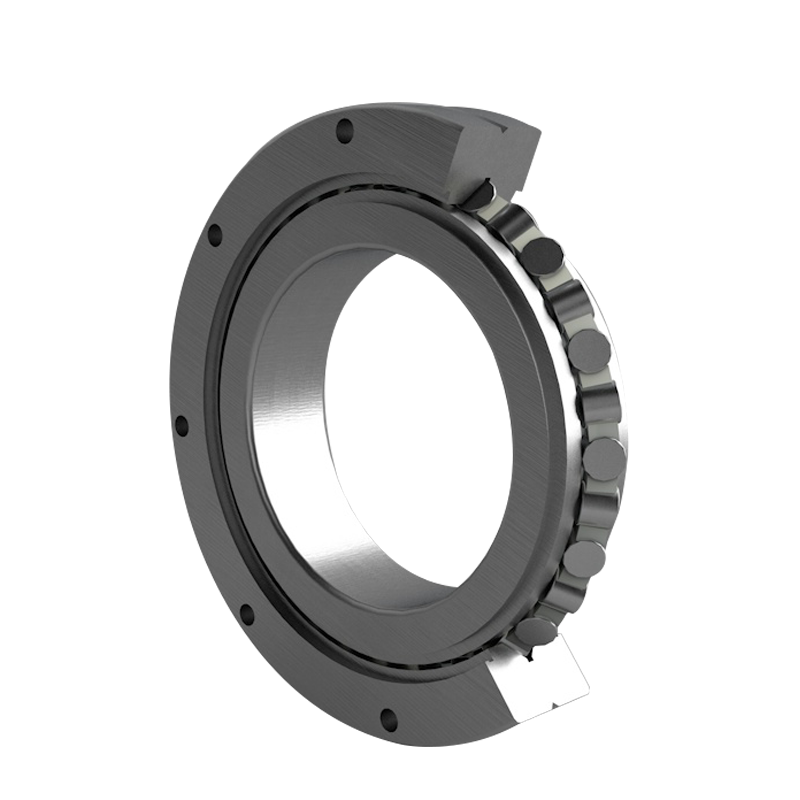

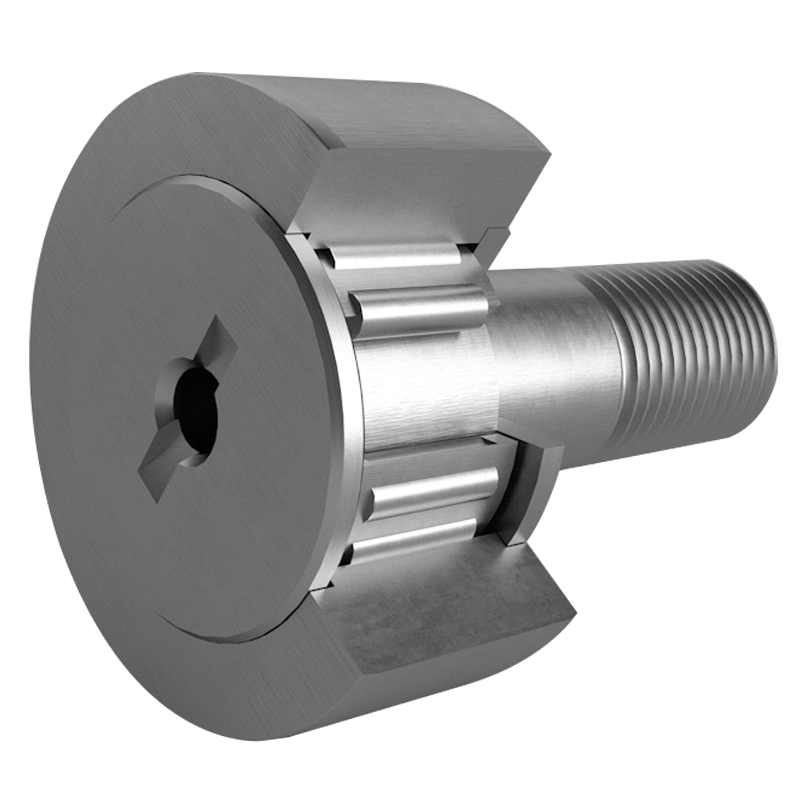

Rotary Table Load: For CNC machine tools and multi-axis machine tools, needle roller bearings are often used to support the rotating table or tool holder to achieve multi-axis machining and precise positioning.

Table Lifting: Needle roller bearings can also be used in table lifting systems for machine tools to ensure smooth movement of the table in the vertical direction and high-precision position control.

Auxiliary Components: Machine tools also include auxiliary components such as tool magazines, automatic tool change systems, and tool conveyors, which may also use needle roller bearings for efficient operation.

The machine tool industry has extremely high requirements for precision, rigidity and reliability, so needle roller bearings are widely used in it. They can ensure high-precision processing of machine tools, improve production efficiency, and also reduce maintenance costs. Machine tool manufacturers typically select the appropriate type and size of needle roller bearings based on specific application requirements.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation