WEBINAR

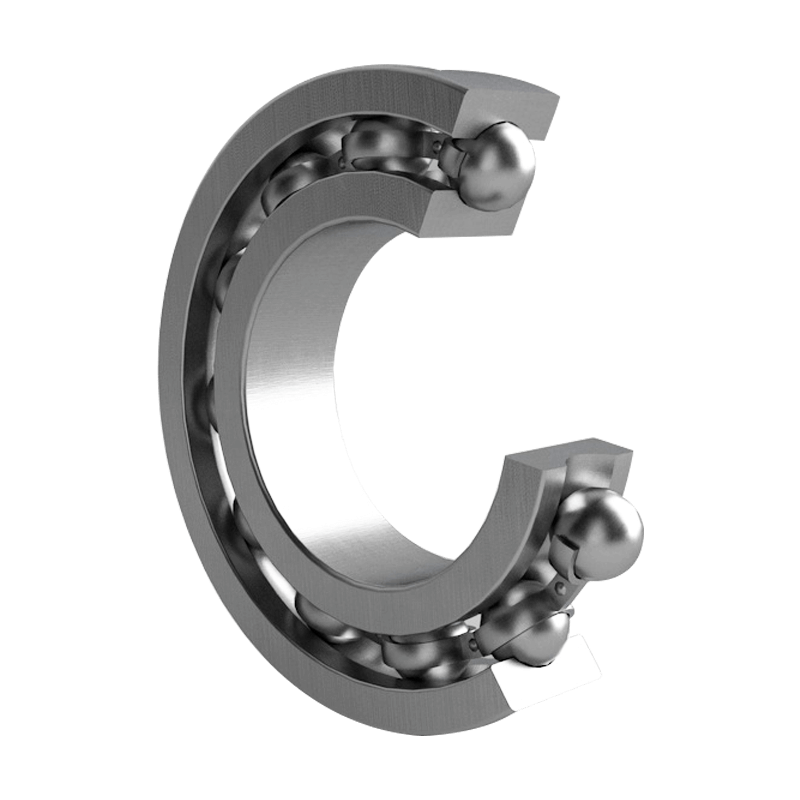

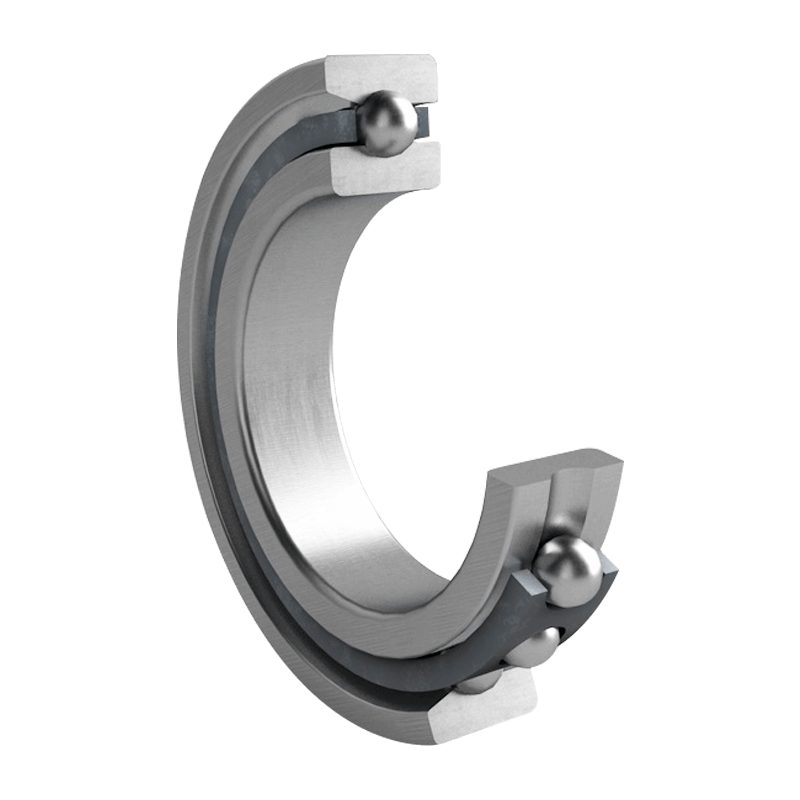

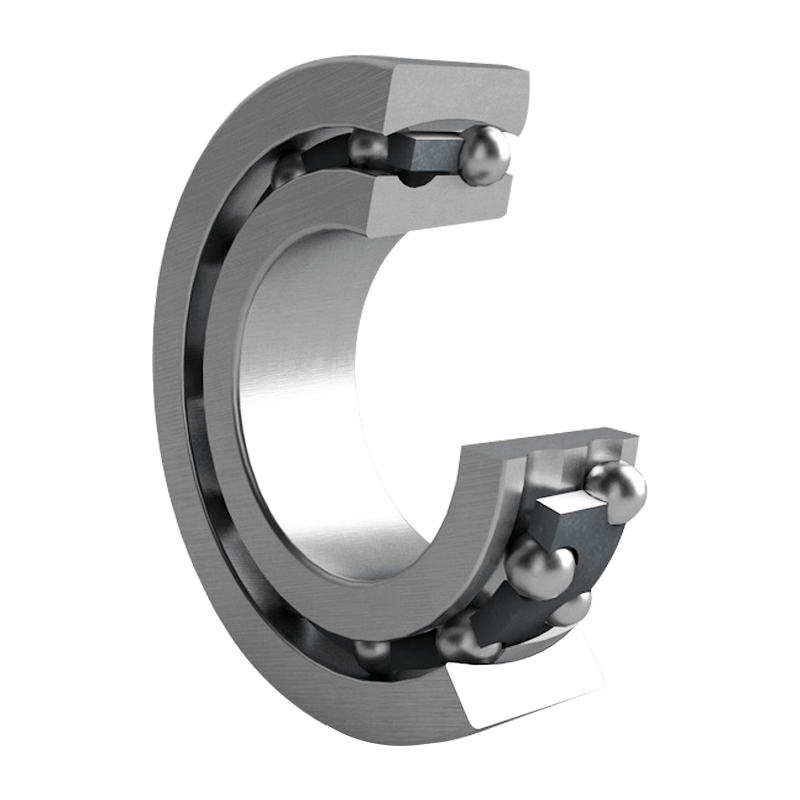

Deep Groove Ball Bearing

Learn More

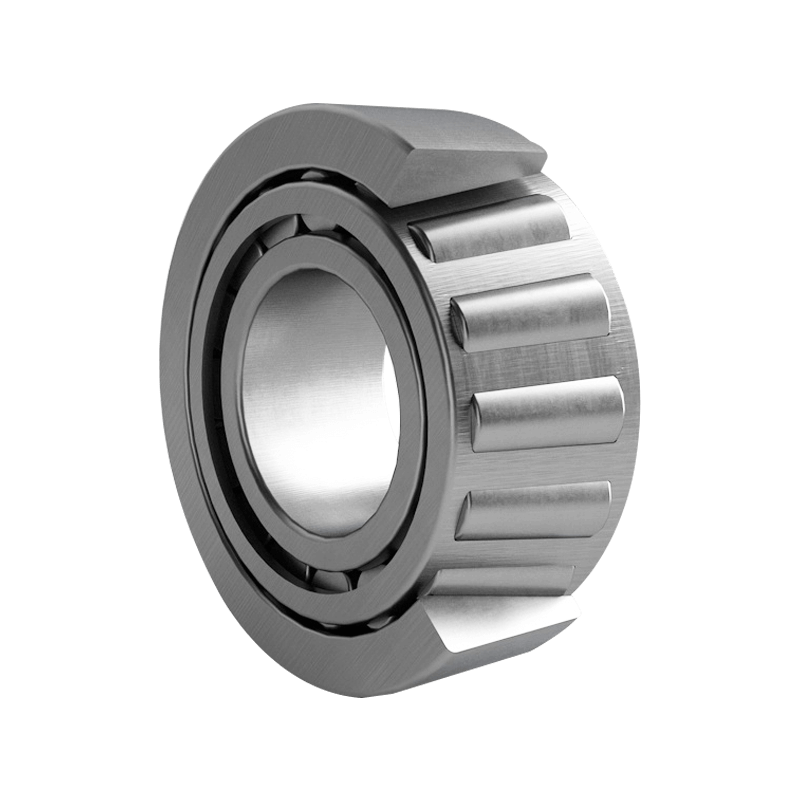

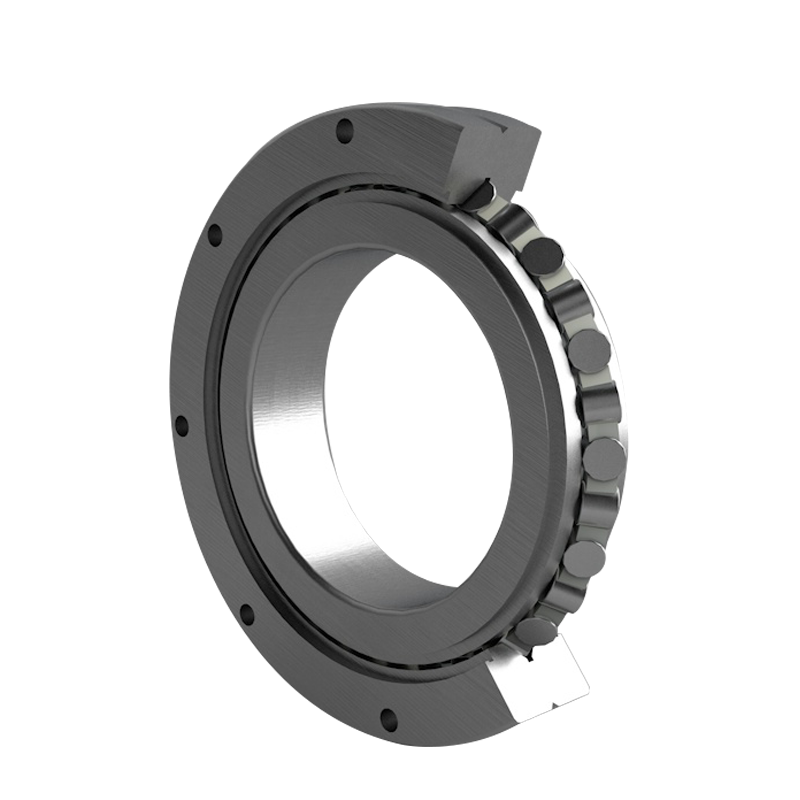

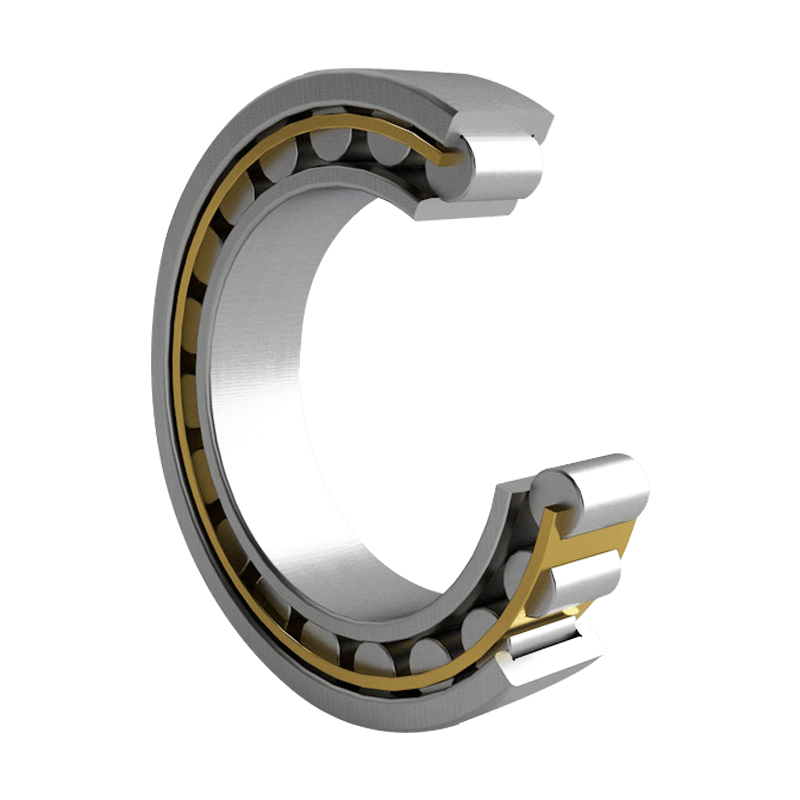

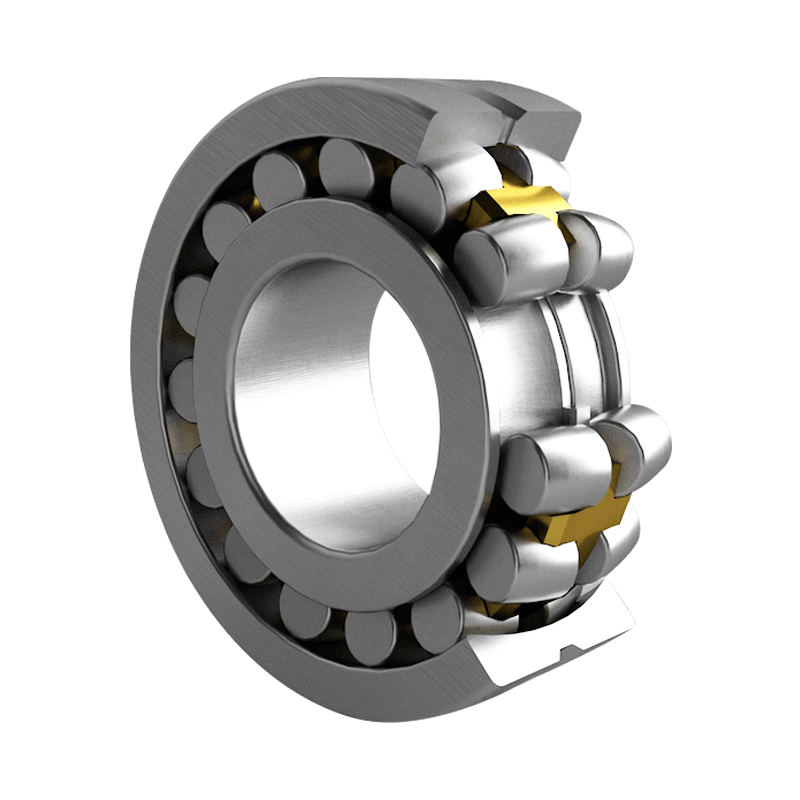

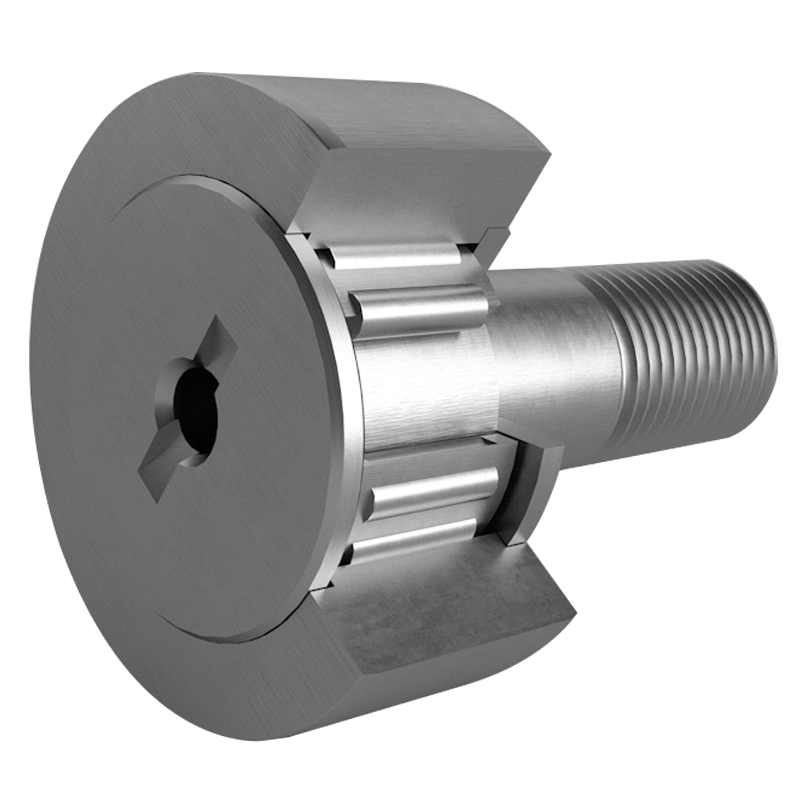

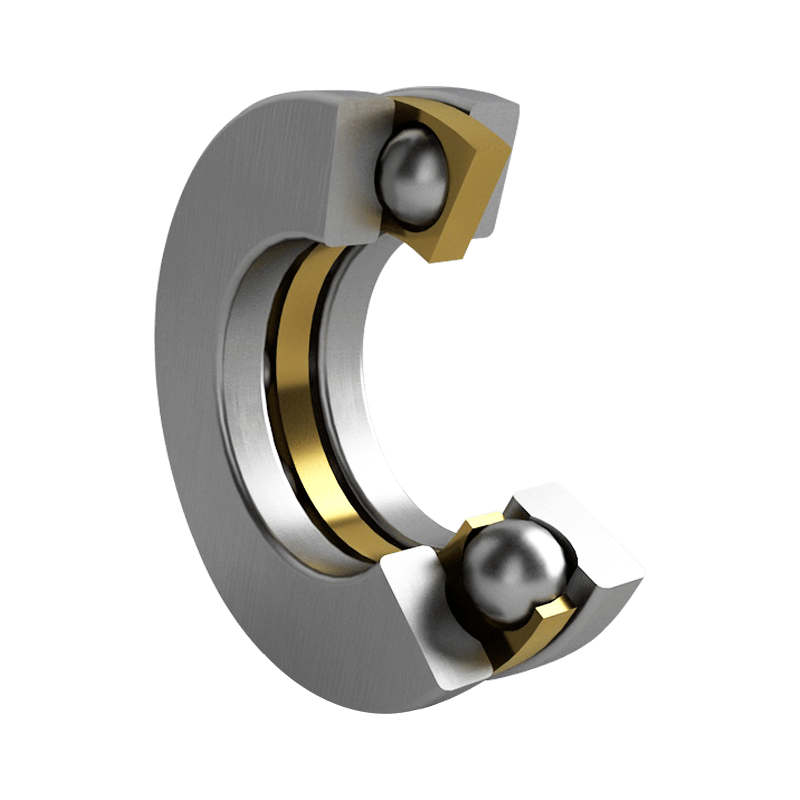

The structure of needle roller bearings is relatively simple and usually consists of several basic parts that work together to support and transfer loads.

The following are the main components of needle roller bearings:

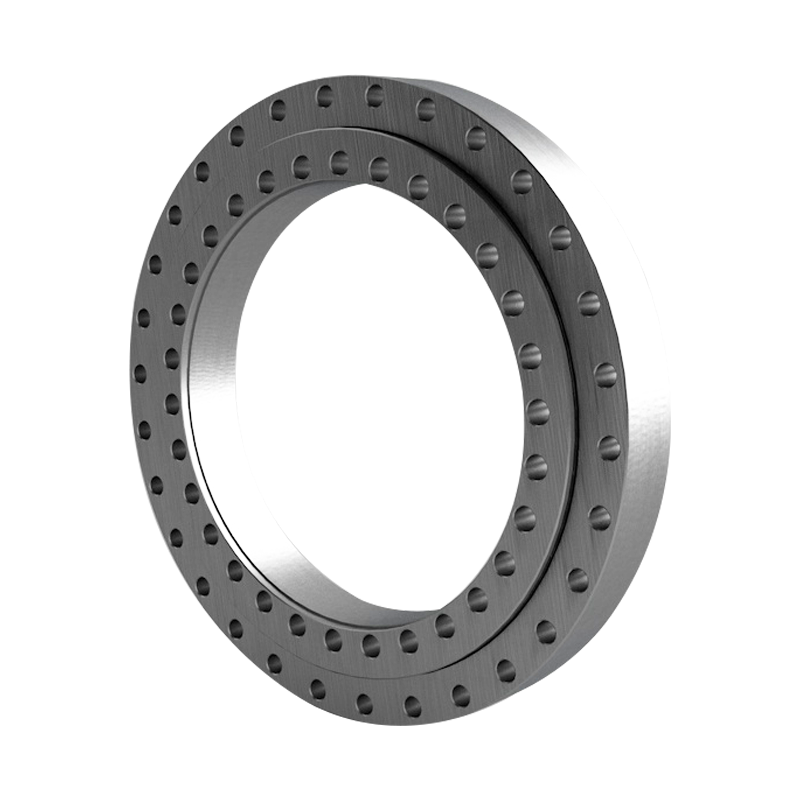

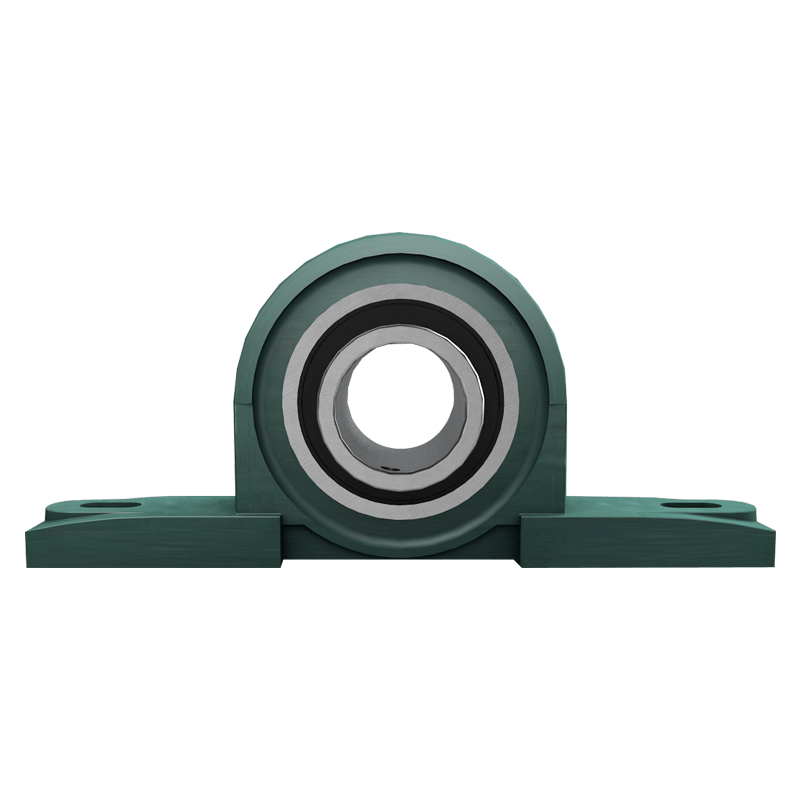

Inner Ring: The inner ring is the internal annular part of a needle roller bearing and is usually made of steel or other metals. The inner ring is designed to be fixed on the rotating shaft to enable the bearing to rotate.

Outer Ring: The outer ring is the outer annular part of the bearing and is usually also made of metal materials. The function of the outer ring is to support and fix the bearing and transfer the load to the bearing seat or mechanism.

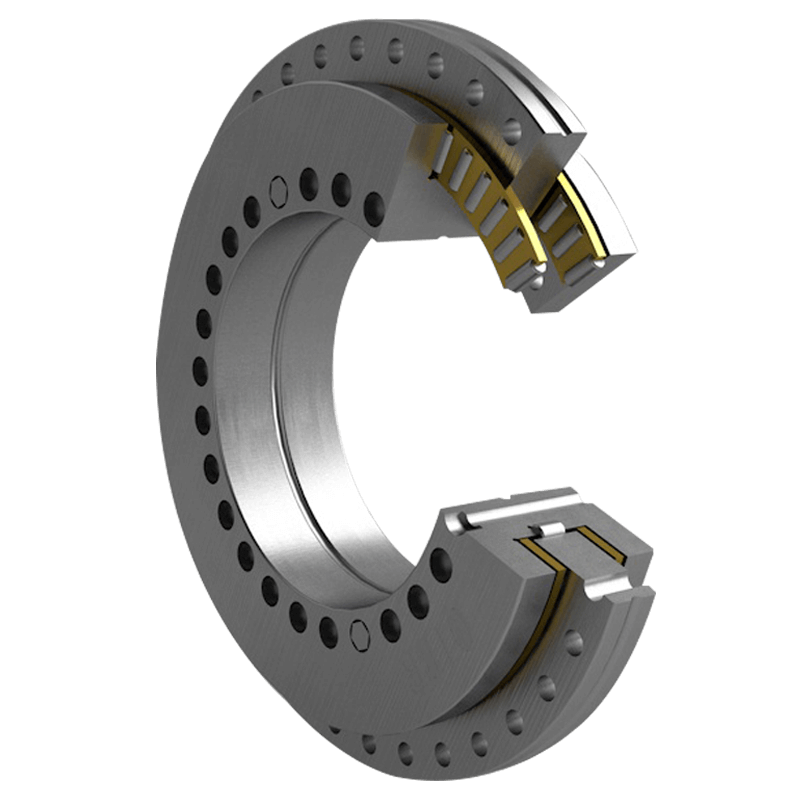

Needle Rollers: Needle rollers are the main rolling elements of needle roller bearings. They are elongated cylindrical rollers, usually made of steel, arranged in one or more rows along the bearing between the inner and outer rings. The rolling motion of the needle rollers reduces friction, supports and transfers loads.

Cage: The cage is the part used to hold and position the needle rollers. It's usually made of metal or plastic, and its design helps keep the rollers evenly distributed to ensure they roll freely and don't bump into each other.

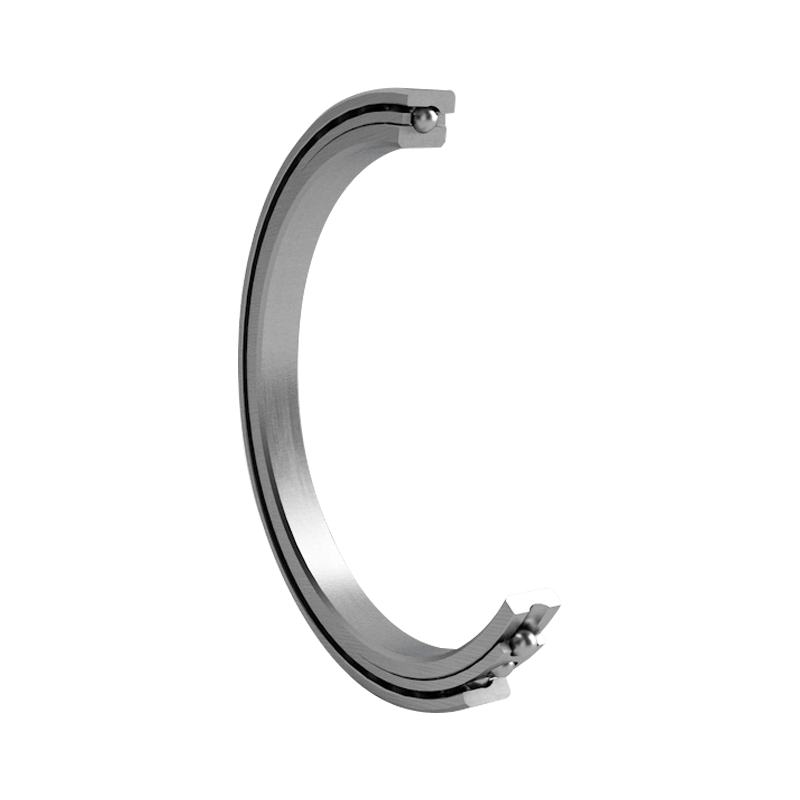

Seals or Covers: Some needle roller bearings may contain seals or covers to prevent external contaminants, dust, or lubricant from leaking into the bearing interior. This helps extend bearing life and maintain performance

Lubricants: Lubricants are a key component of needle roller bearings and are used to reduce rolling friction, cool the bearings and mitigate wear. Lubricants can be oil or grease, and they must be maintained and replaced regularly to ensure the good operation of the bearings.

These components work in tandem to enable needle roller bearings to support and transfer loads and reduce rolling friction, thus achieving efficient rotary motion. Depending on the specific application and requirements, needle roller bearings may vary in construction and material to meet the needs of different loads and environmental conditions.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation