WEBINAR

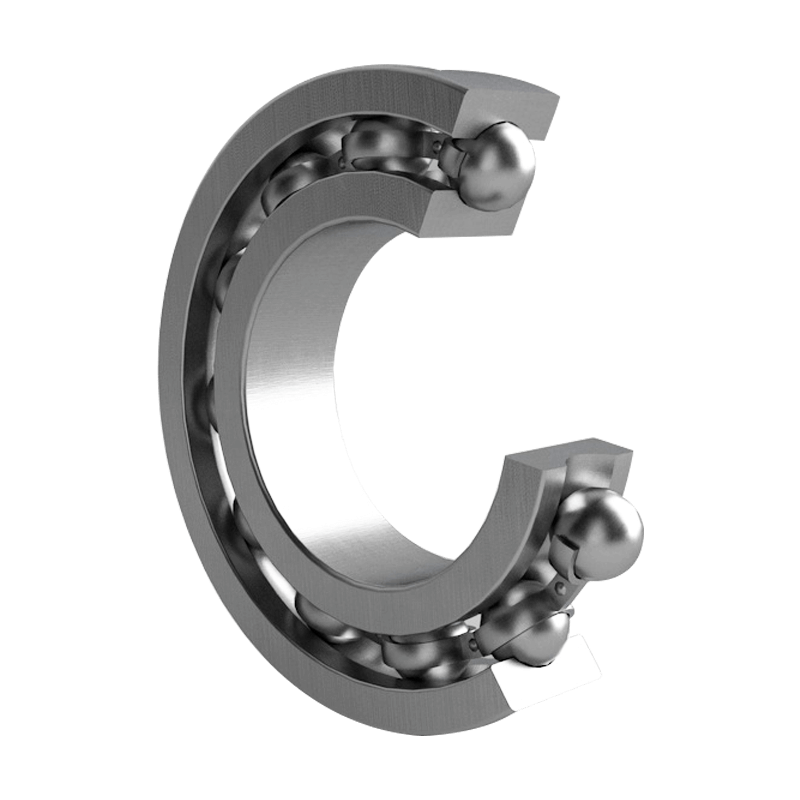

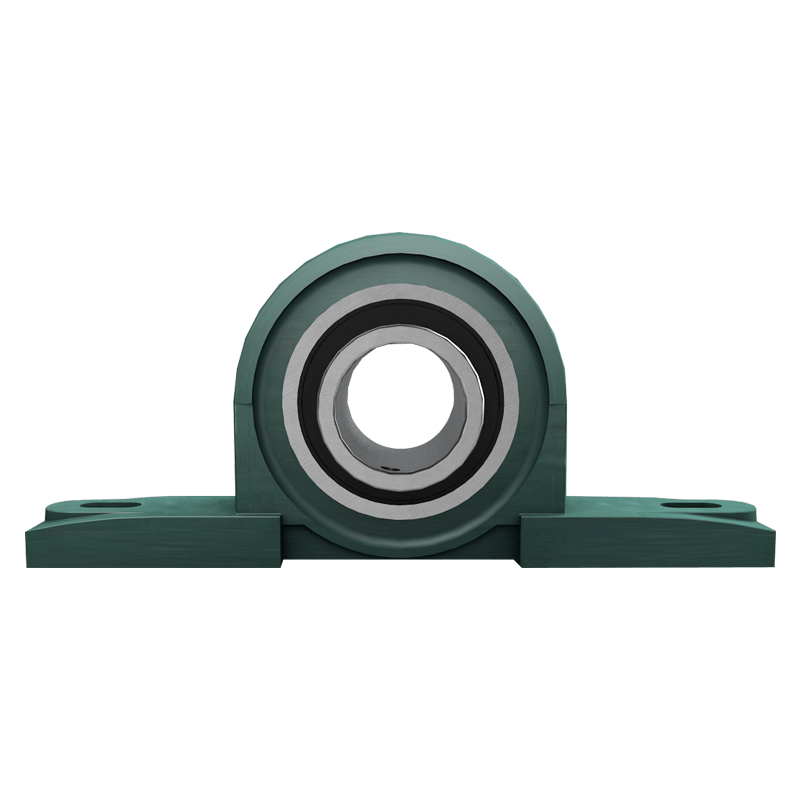

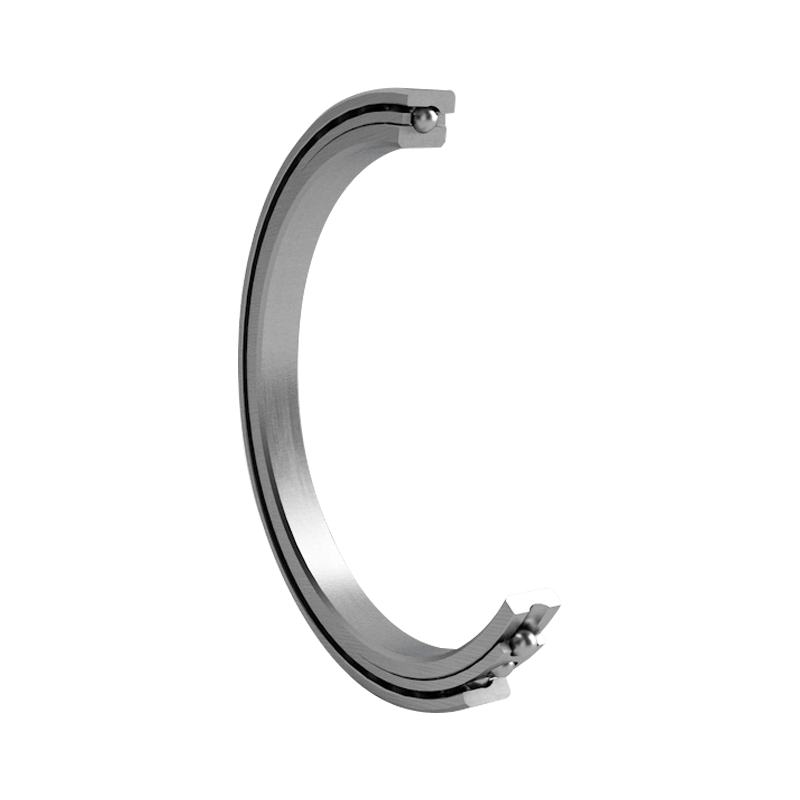

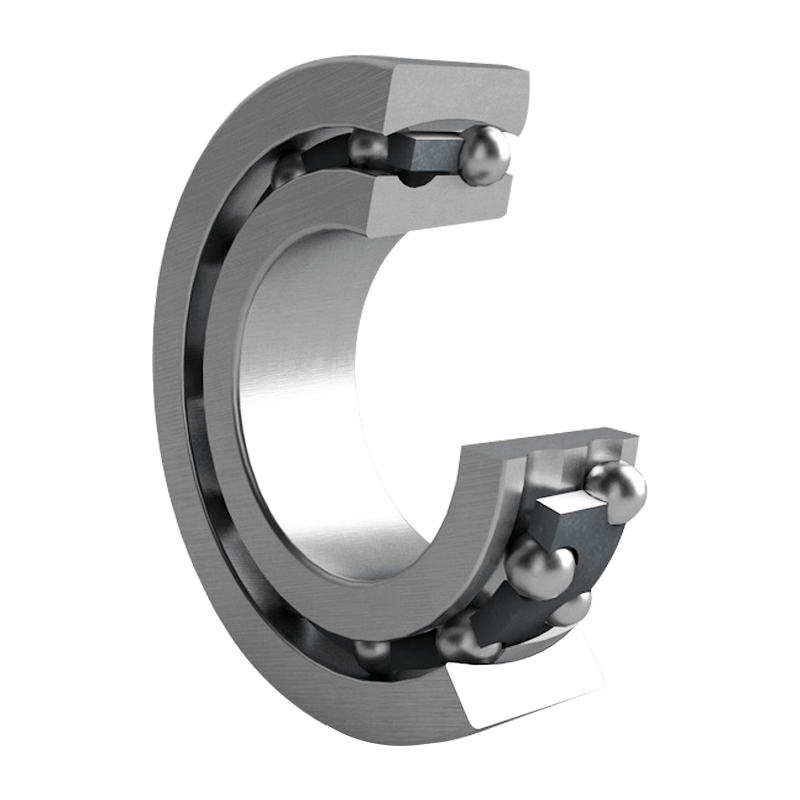

Deep Groove Ball Bearing

Learn More

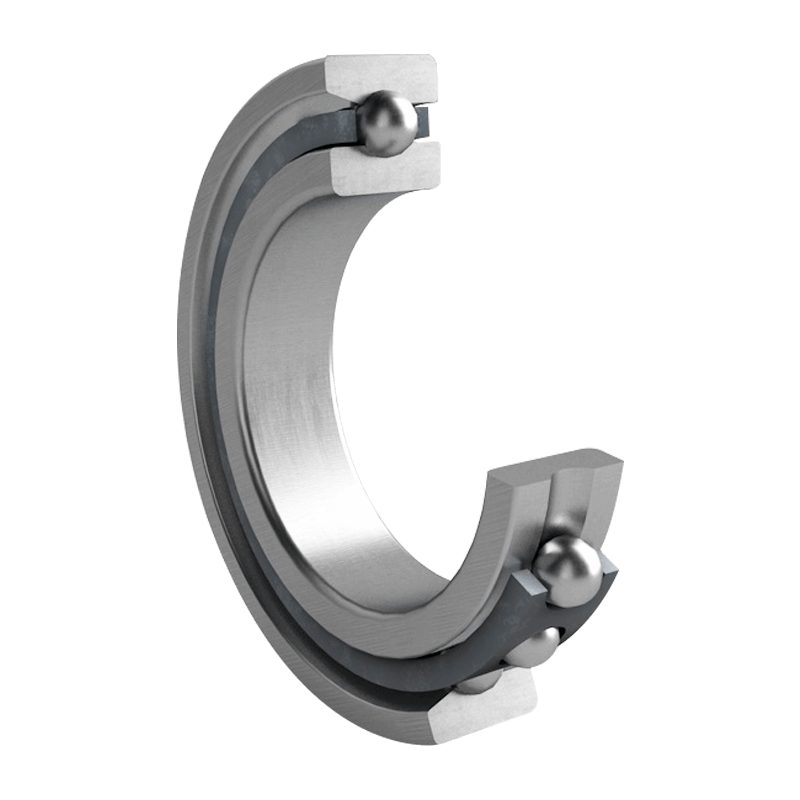

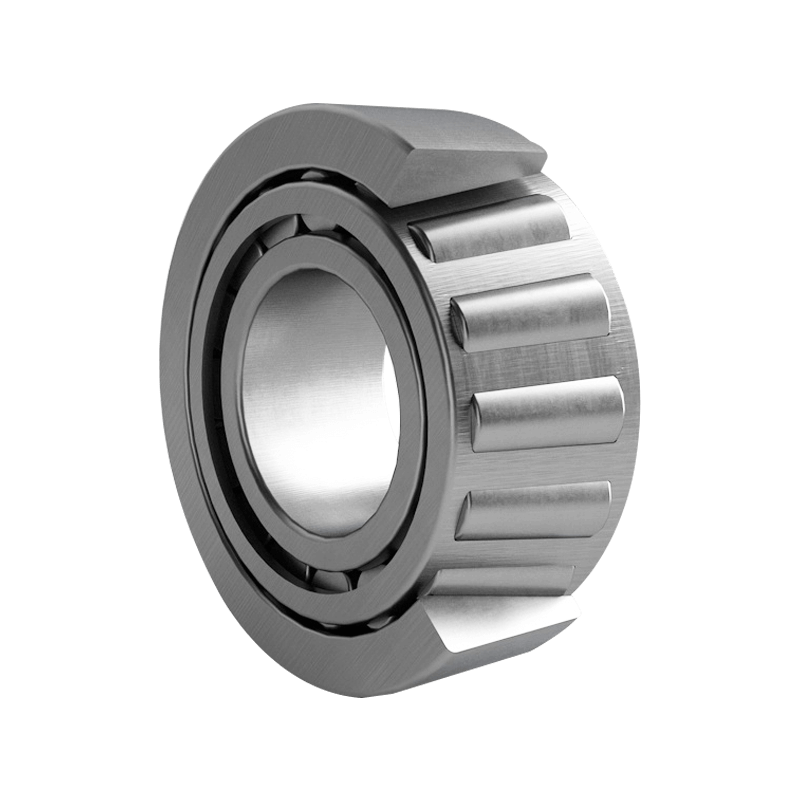

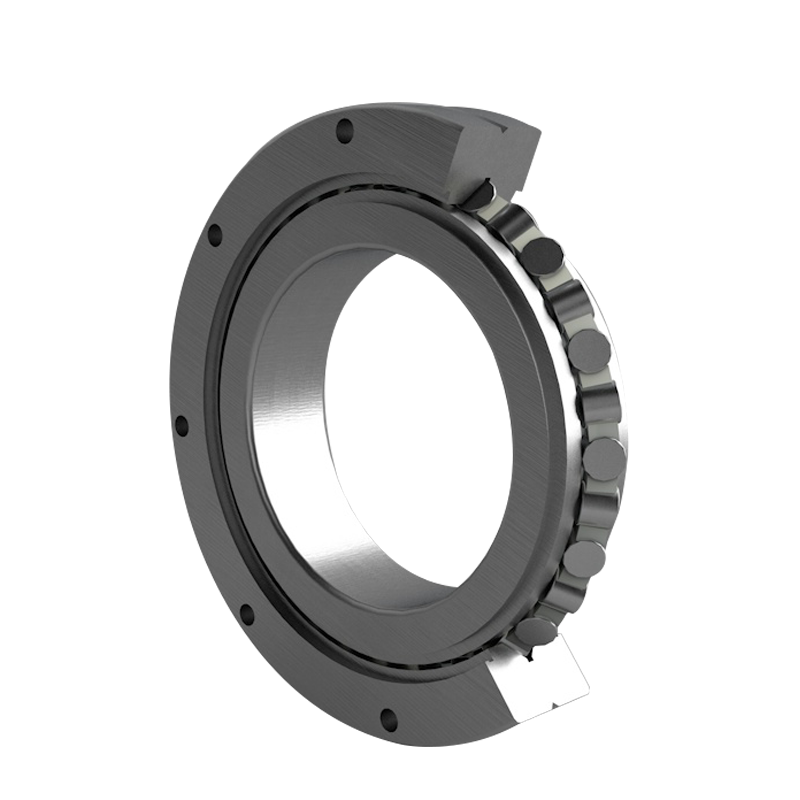

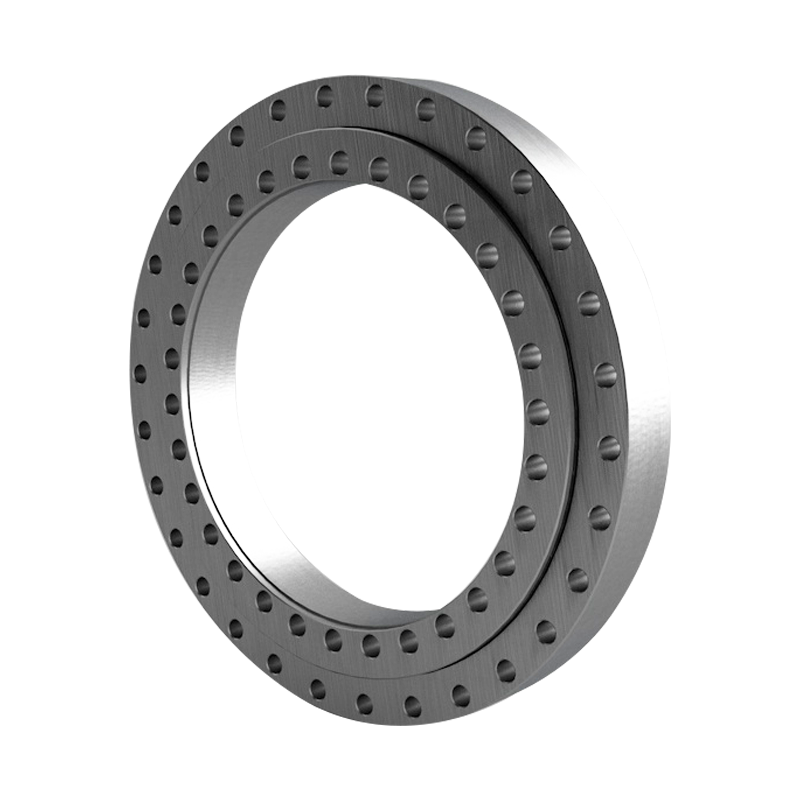

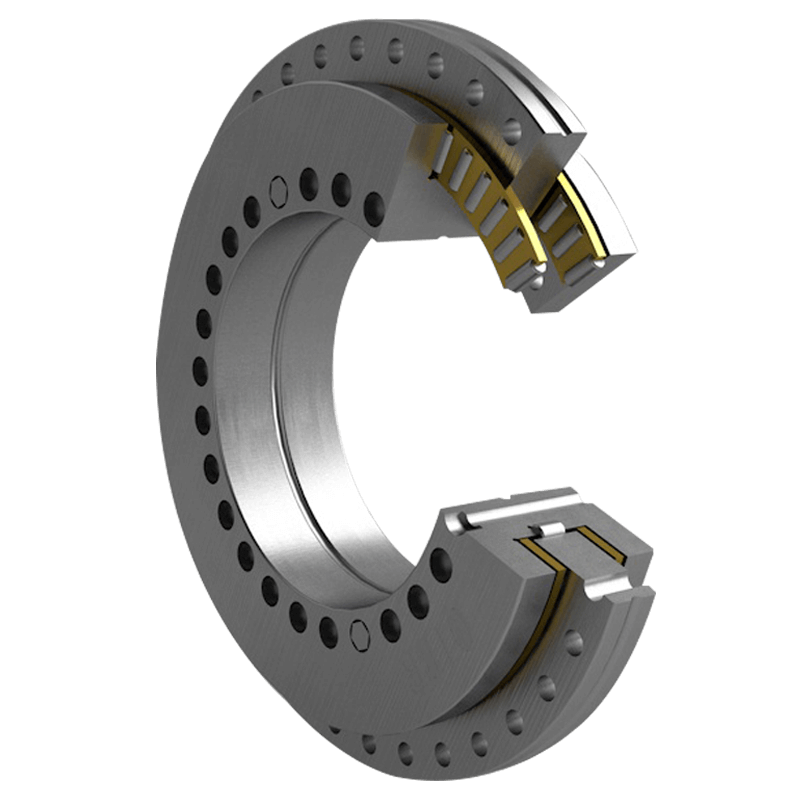

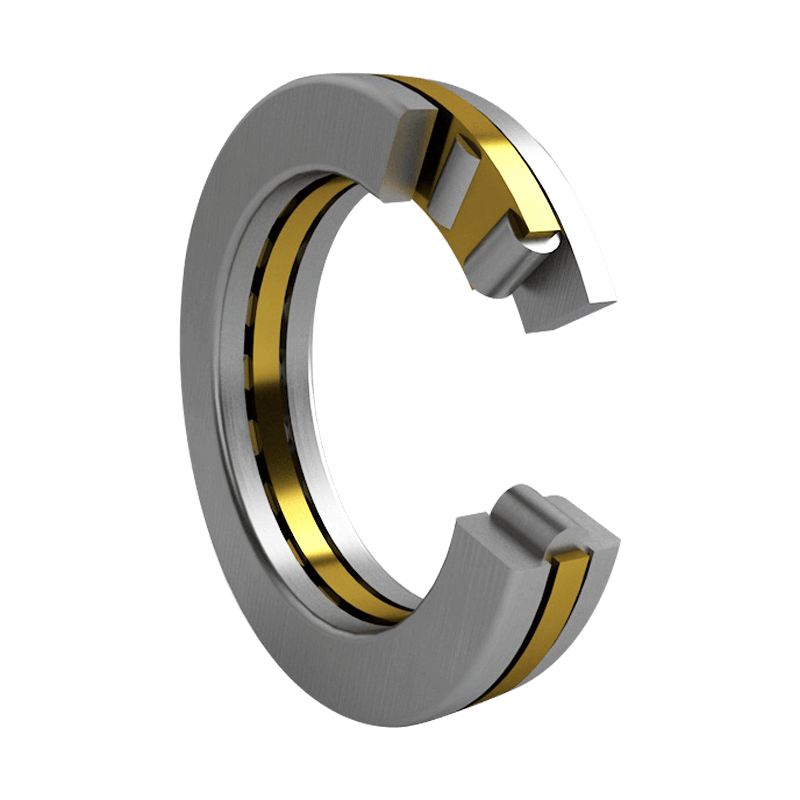

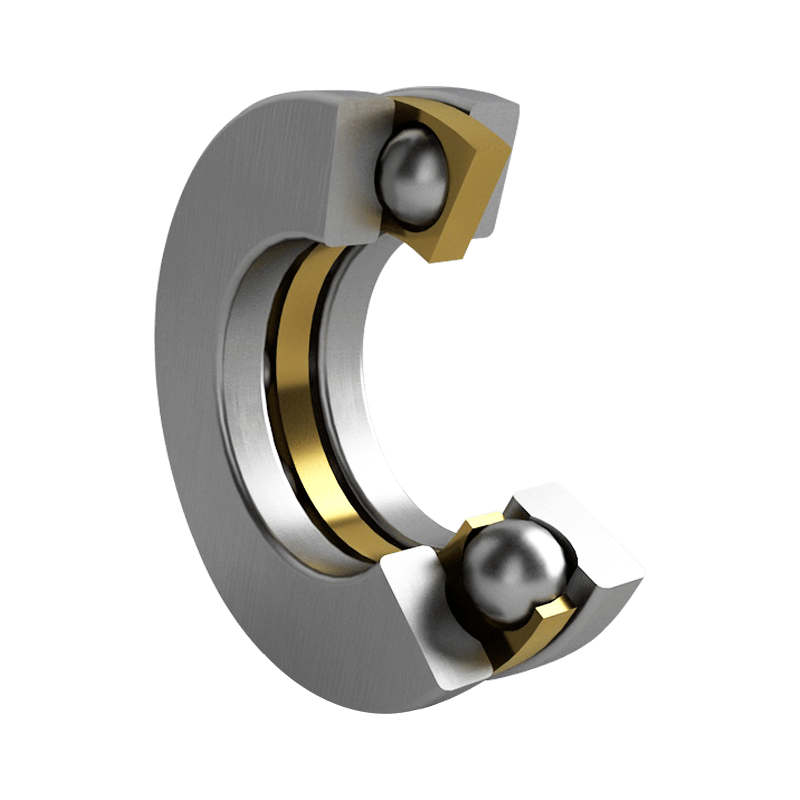

Thrust ball bearing is a rolling bearing used to bear axial load. Its basic principle and working principle are as follows:

The basic principle of thrust ball bearings is to reduce friction under axial loads through rolling elements (usually balls or cylinders). These rolling elements are arranged between the inner and outer rings of the bearing, and the rolling motion between them reduces the friction exerted on the bearing by axial loads. Thrust ball bearings are usually used to bear unidirectional axial loads, but there are also thrust ball bearings that bear axial loads in both directions.

The working principle of thrust ball bearings can be briefly described as:

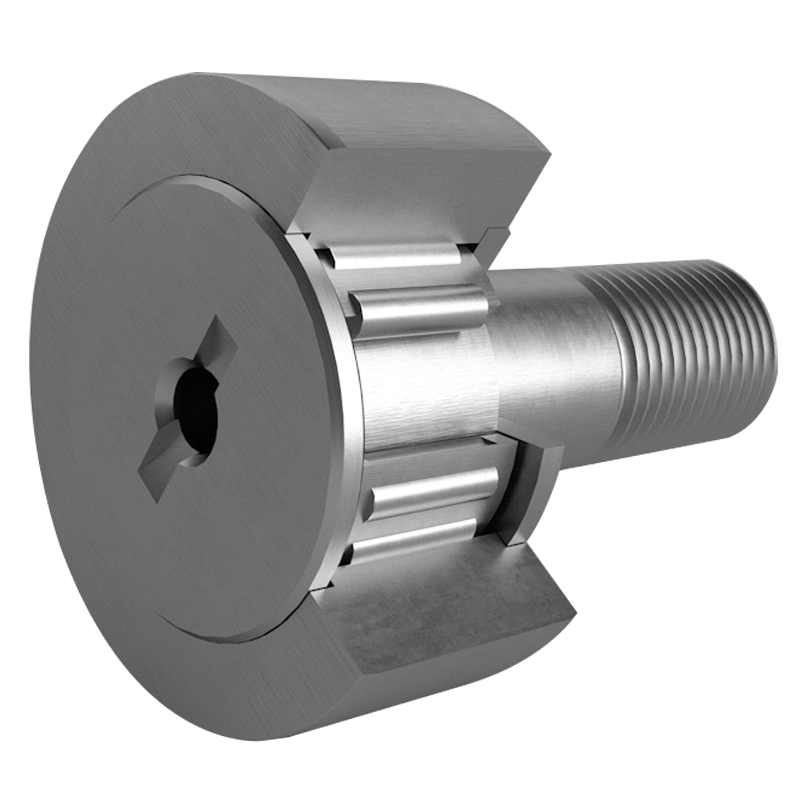

Load Application: When an axial load is applied to a bearing, the load is transferred to the rolling elements.

Rolling Motion: Rolling elements (usually balls) roll between the inner and outer rings, reducing the friction exerted on the bearing by the load. The rolling motion is guided by raceways (grooves on the inner and outer rings) along which rolling elements roll.

Reduced Friction: Due to the rolling motion of the rolling elements, thrust ball bearings reduce friction under axial load compared to sliding bearings, which helps reduce energy loss and wear.

Support Axial Load: Thrust ball bearings support axial load through the rolling motion of rolling elements, allowing the load to be transmitted along the axis of the bearing.

It is important to note that thrust ball bearings generally require proper alignment and lubrication when installed to ensure they function properly and provide optimal performance. In addition, the design and material of the bearing will also affect its endurance and life.

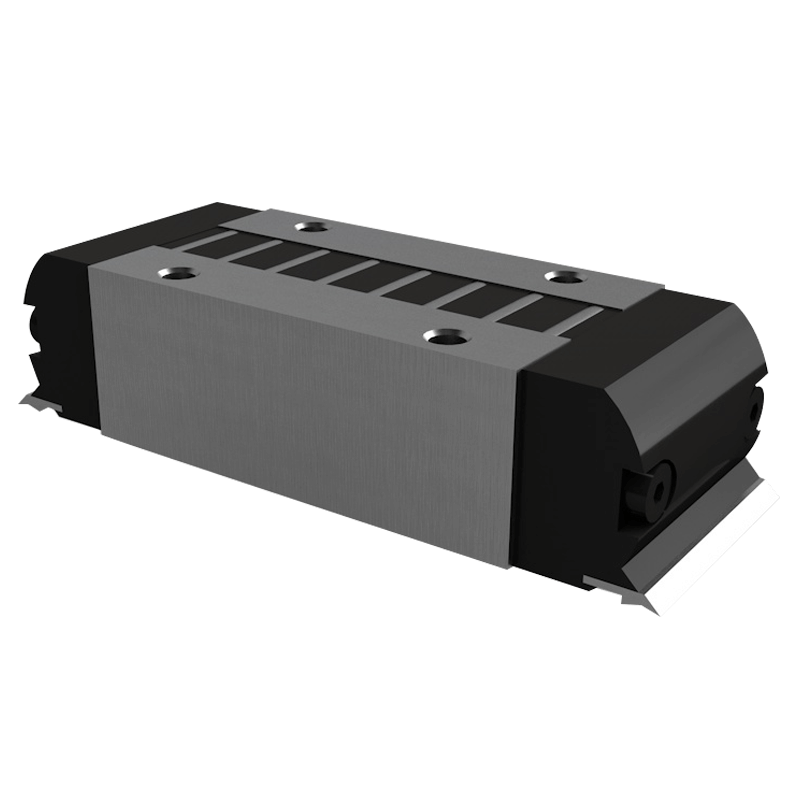

Thrust ball bearings are widely used in a variety of applications, including mechanical transmissions, automotive transmission system, wind turbines, aerospace equipment, etc. They provide solutions for efficiently carrying axial loads.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation