WEBINAR

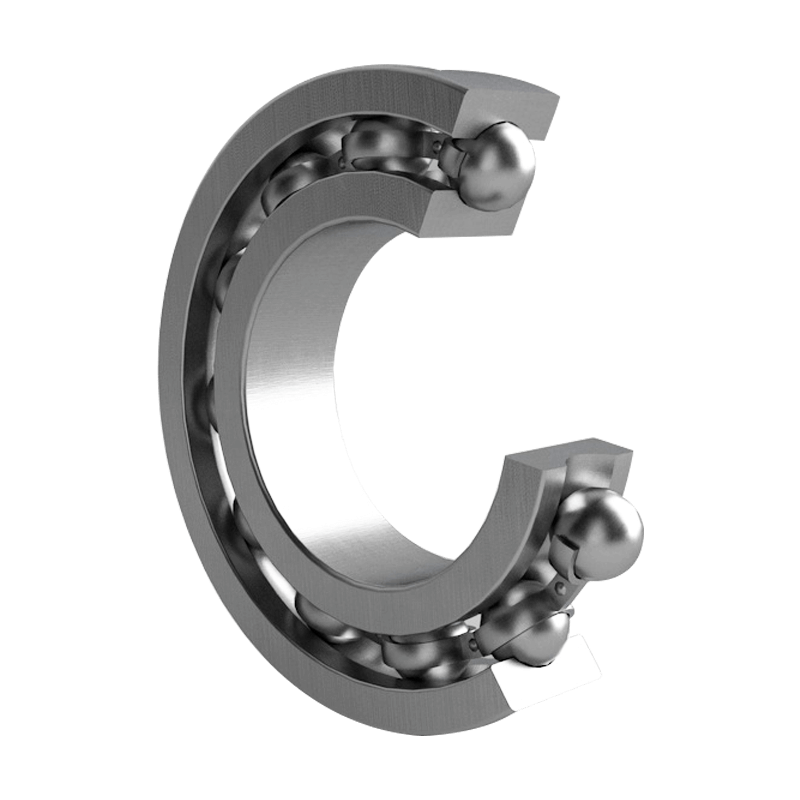

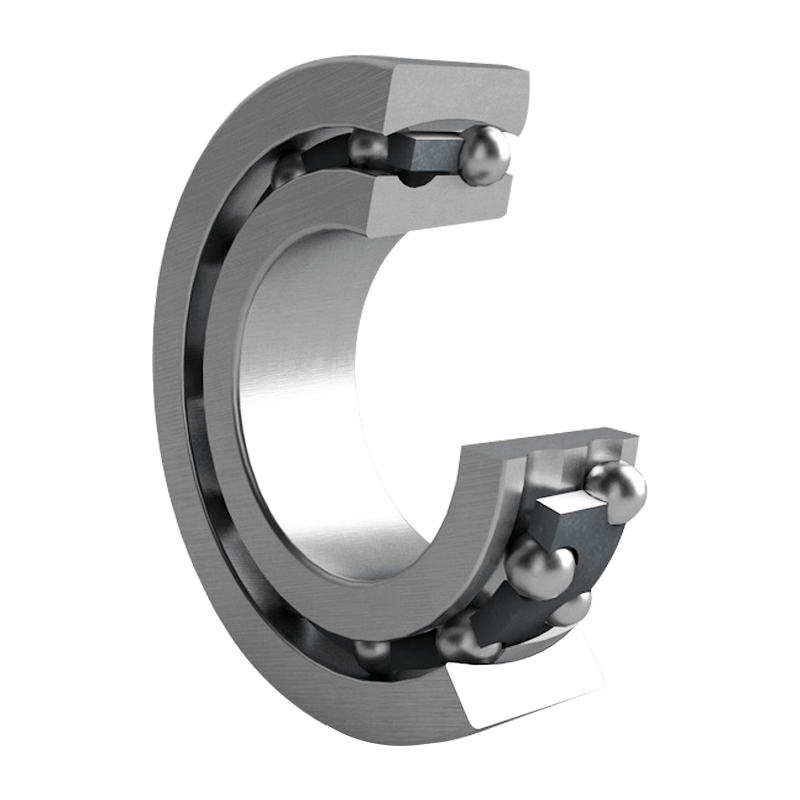

Deep Groove Ball Bearing

Learn More

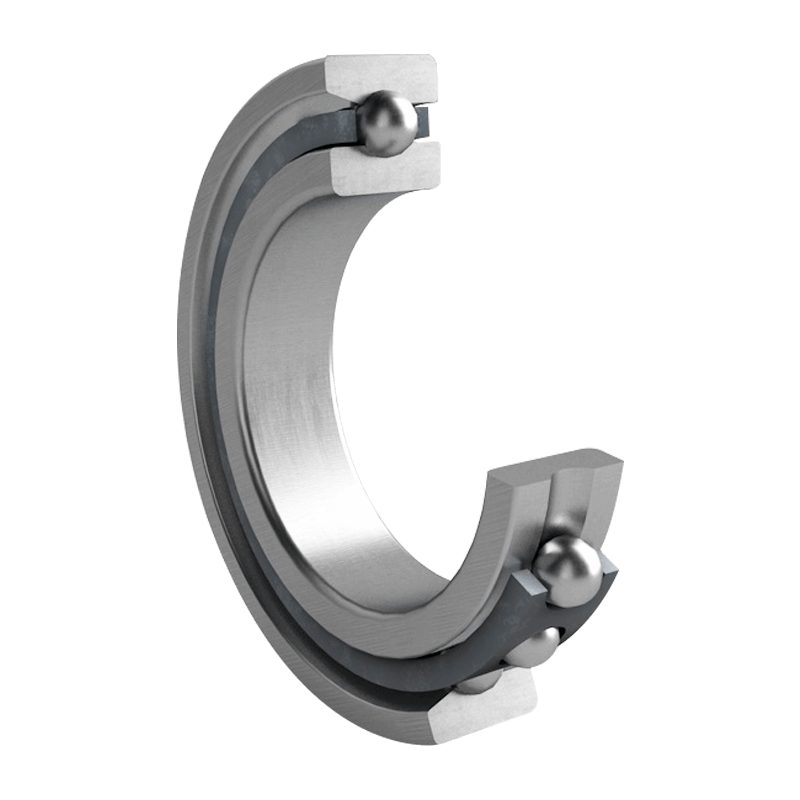

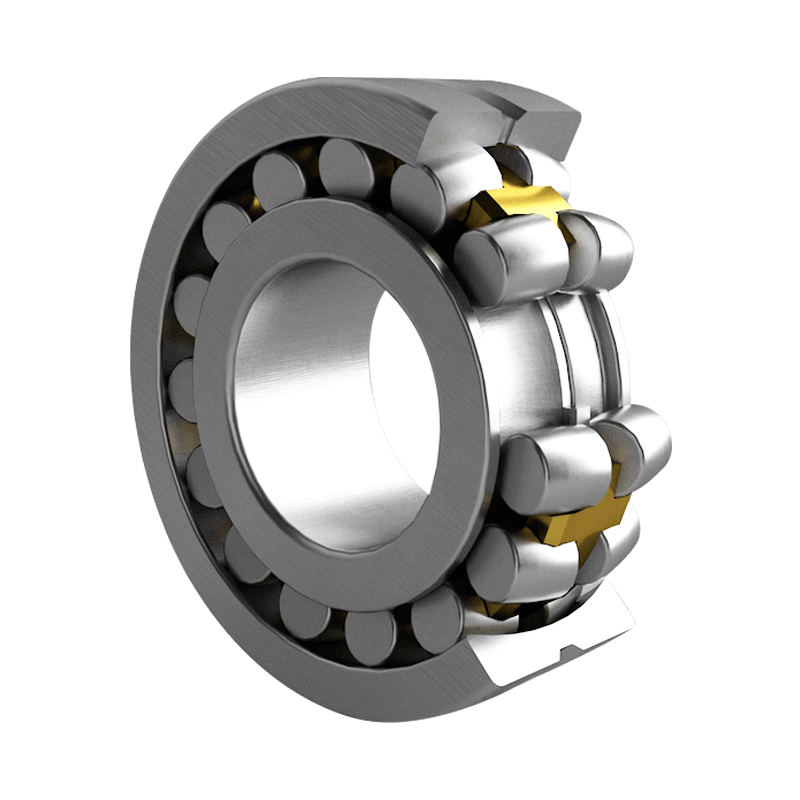

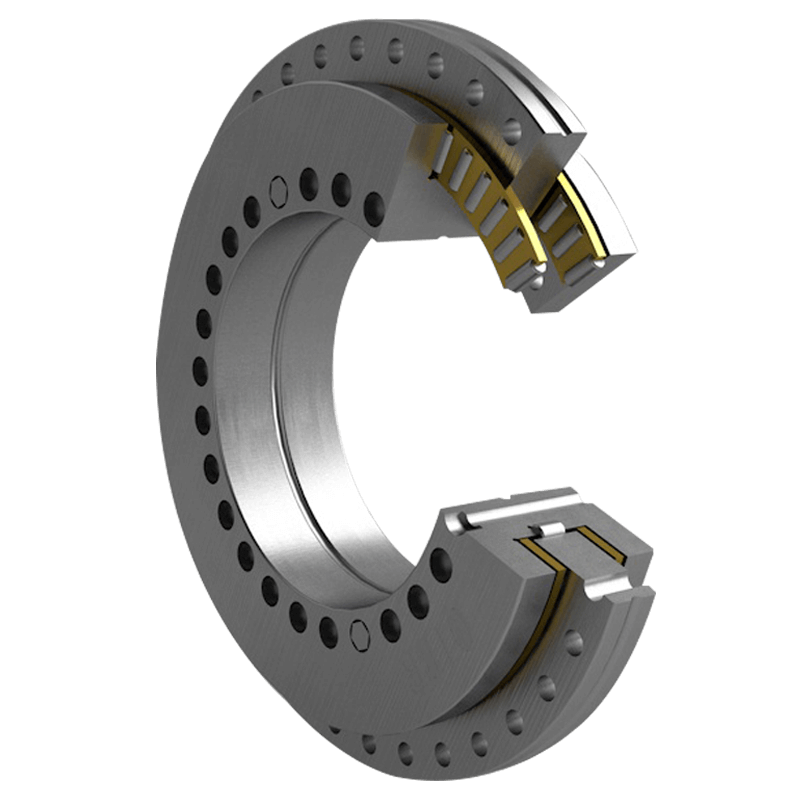

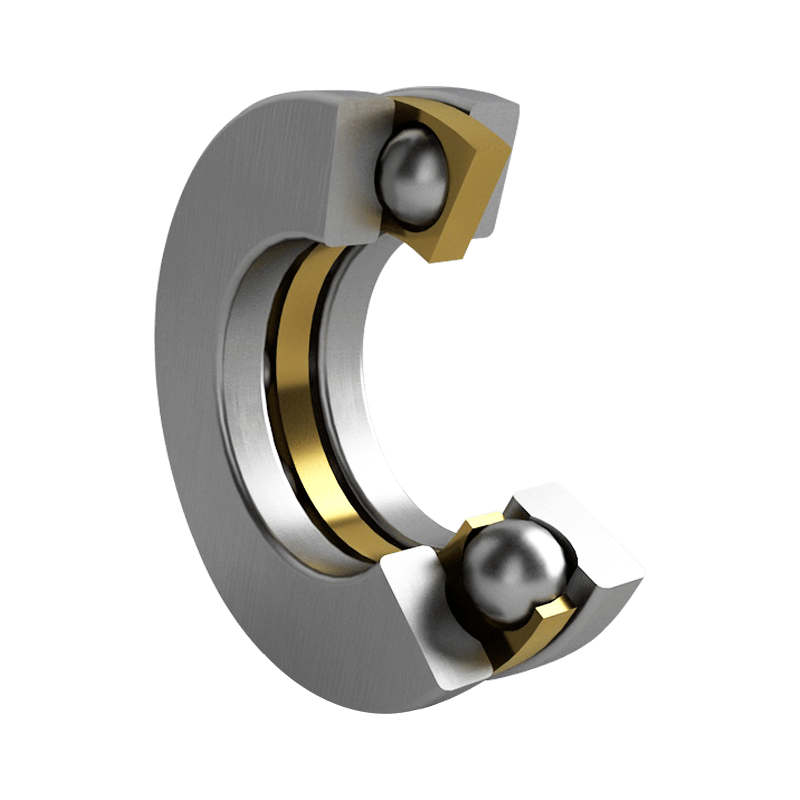

The working principle and operation method of angular contact ball bearings are as follows:

The working principle of angular contact ball bearings is based on the contact angle between the ball and the raceway. The raceway between the inner and outer rings of these bearings is angled, and the contact angle between the ball and raceway is typically 30 or 40 degrees, depending on the bearing design. This contact angle enables the bearing to bear both radial and axial loads.

When load is applied to a bearing, it will create a pressure area at the point of contact between the ball and raceway. Due to the contact angle, this pressure area can divide the load into two components: a radial component, perpendicular to the direction of the bearing axis. And an axial component, parallel to the bearing axis. This allows angular contact ball bearings to carry both types of loads simultaneously.

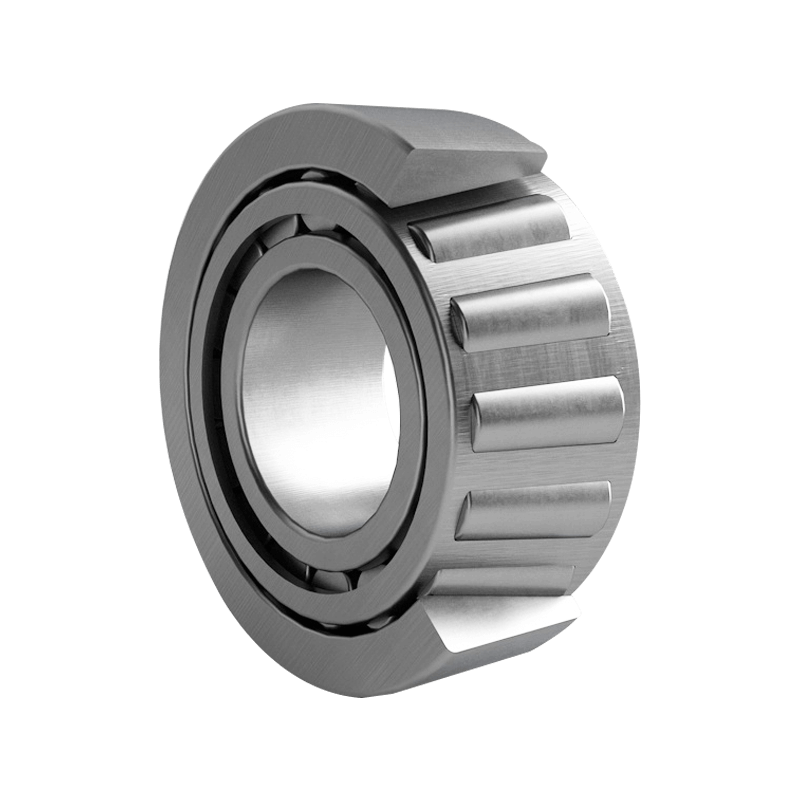

The way angular contact ball bearings operate depends on the type of load applied:

Pure Radial Load: When the bearing is subjected to pure radial load, the raceway between the inner ring and the outer ring will be loaded, and the ball will roll along the raceway to support this radial load.

Pure Axial Load: When the bearing is subjected to pure axial load, the raceway between the inner ring and the outer ring will bear the load, and the ball will roll along the axial direction of the raceway to support this axial load.

Simultaneous Radial and Axial Loads: The advantage of angular contact ball bearings is that they can carry both types of loads simultaneously. The point of contact between the ball and raceway will create a resultant force that supports a combination of radial and axial loads. This gives angular contact ball bearings superior performance under complex load conditions.

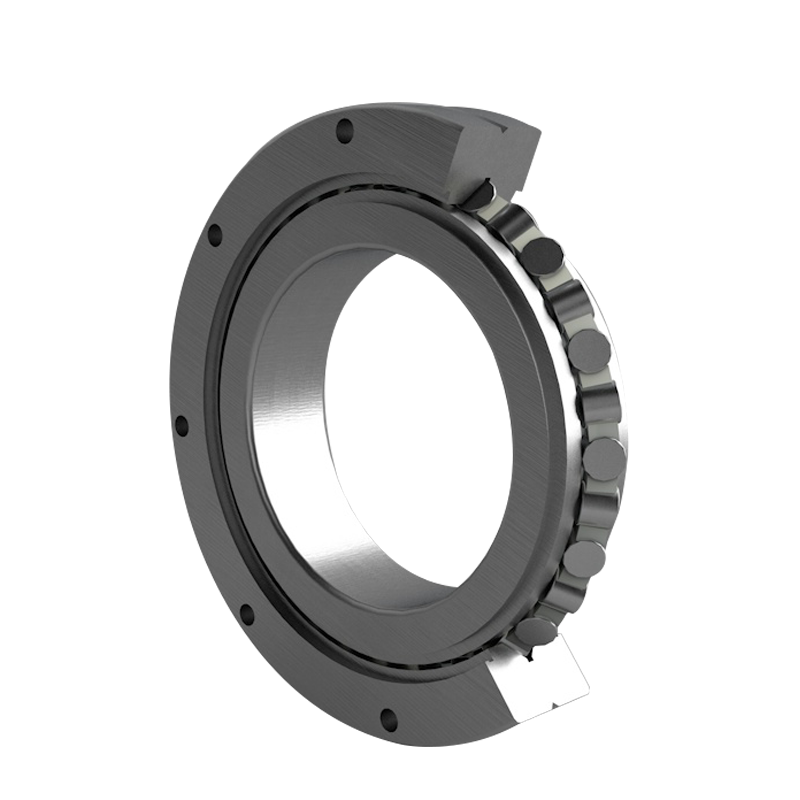

Overall, the working principle of angular contact ball bearings is based on its special structural design, which allows it to effectively support radial and axial loads, and is suitable for various applications that require multi-directional load support, such as machine tools, automobile hubs, and wind turbines.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation