WEBINAR

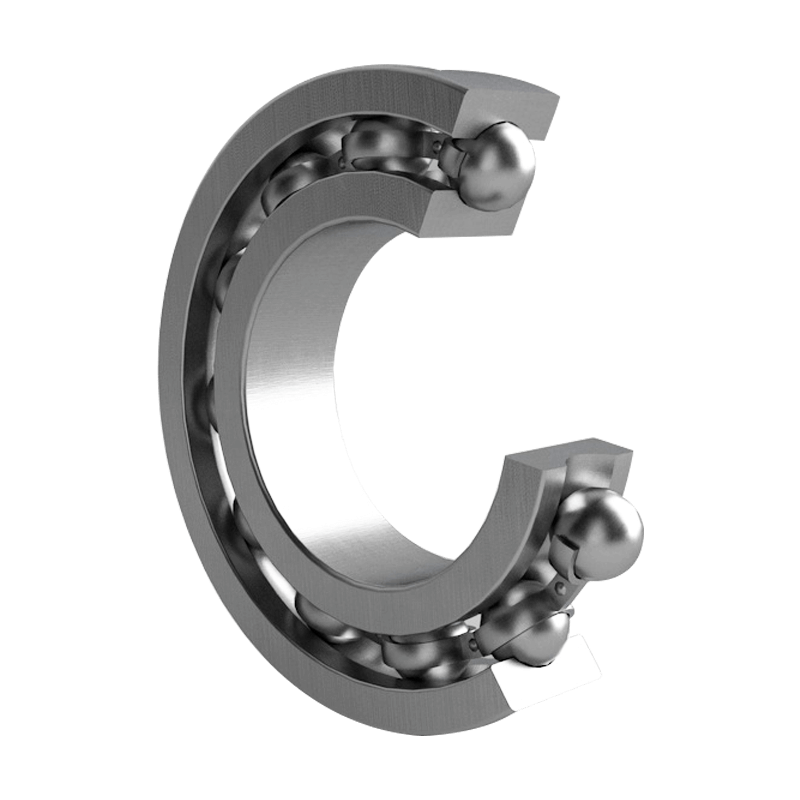

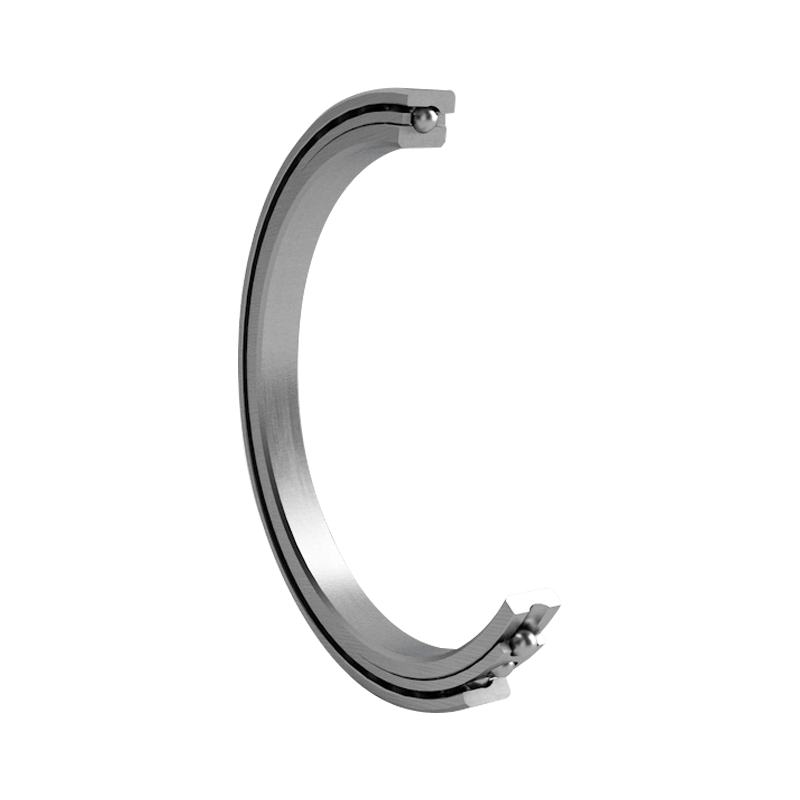

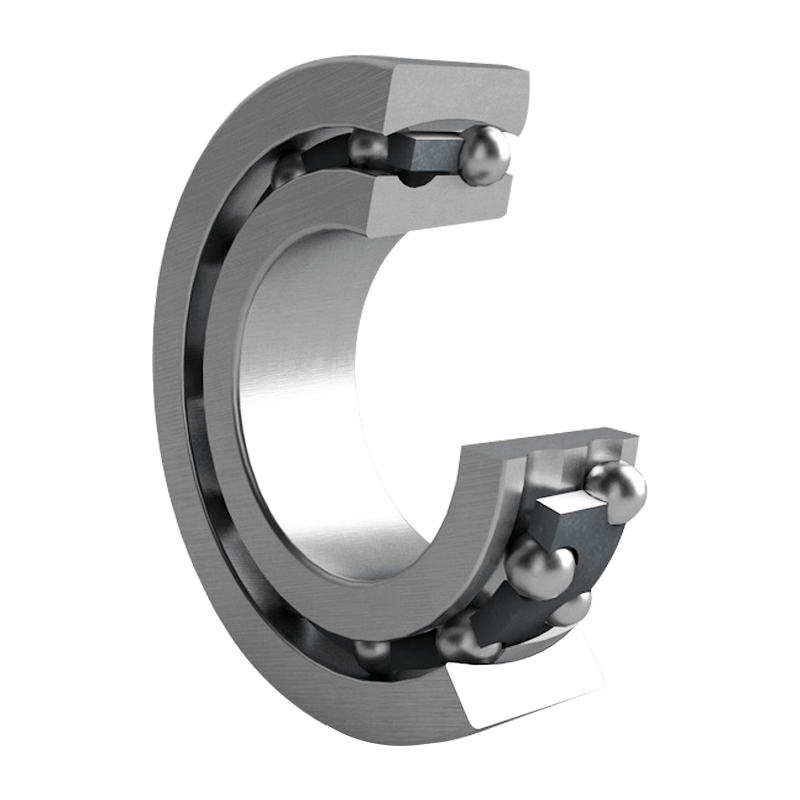

Deep Groove Ball Bearing

Learn More

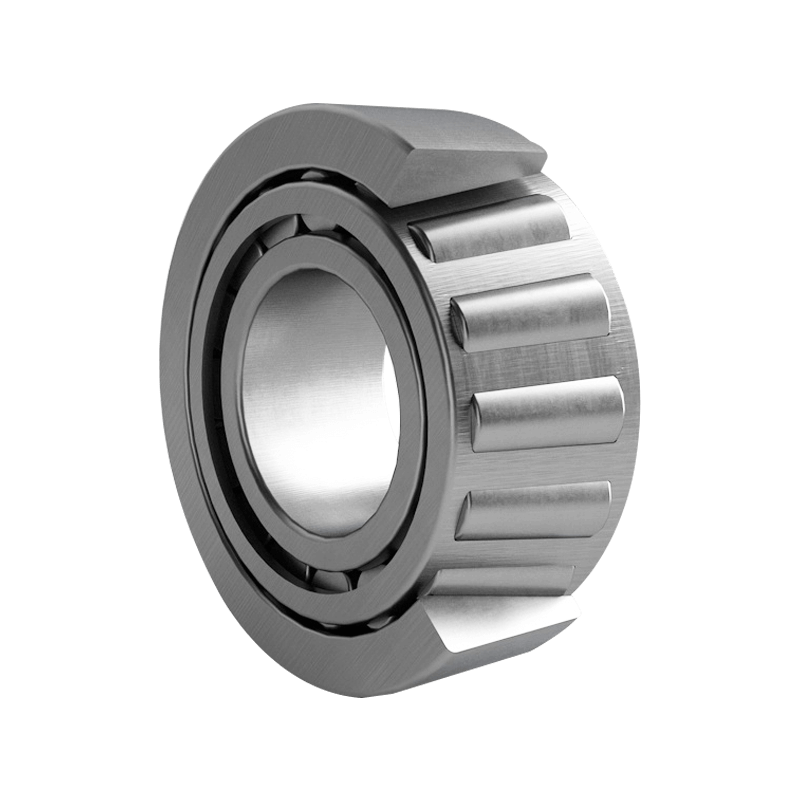

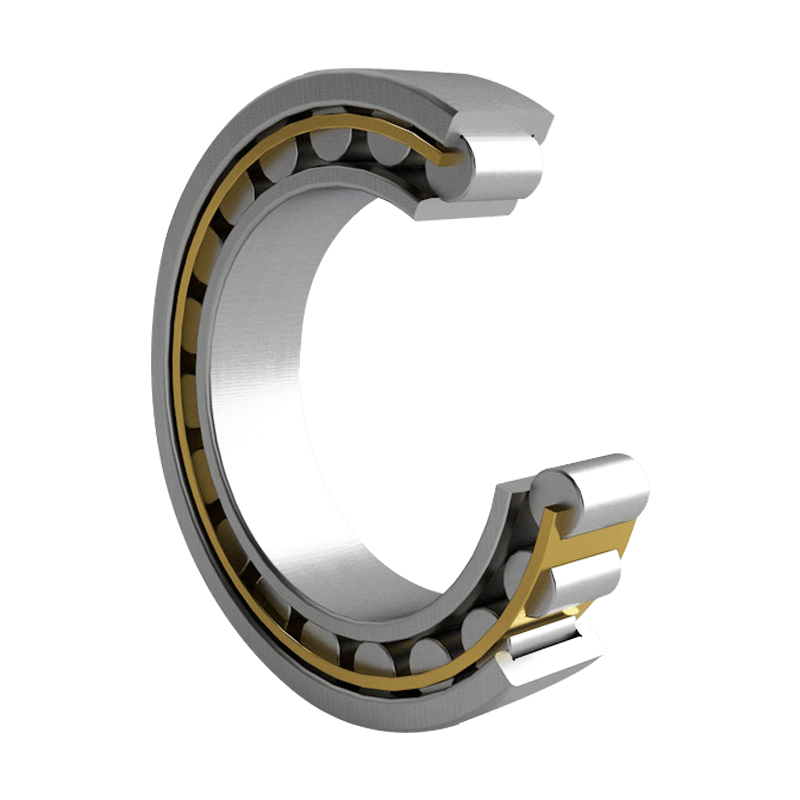

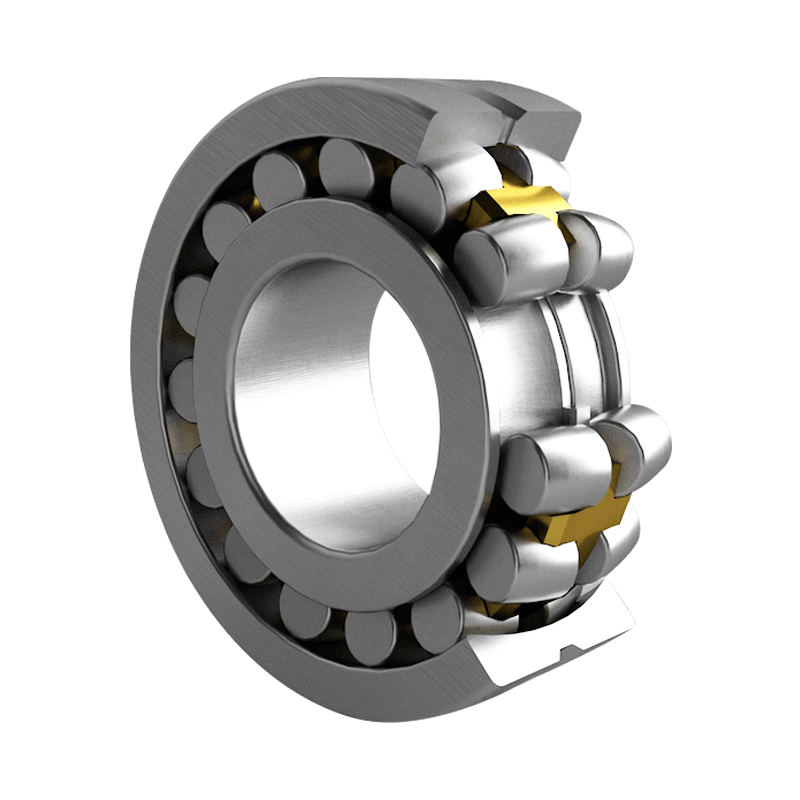

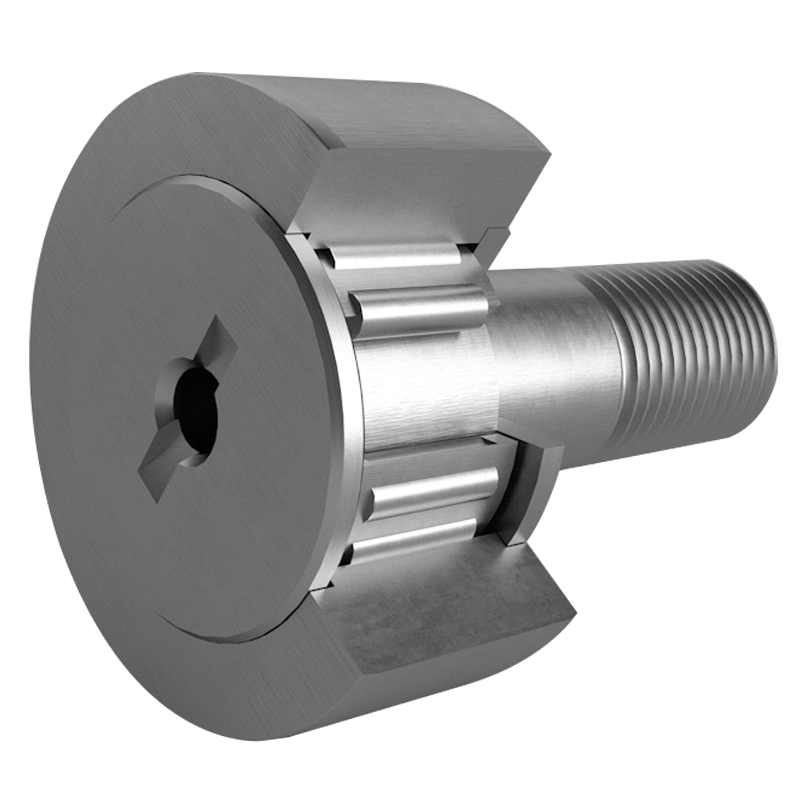

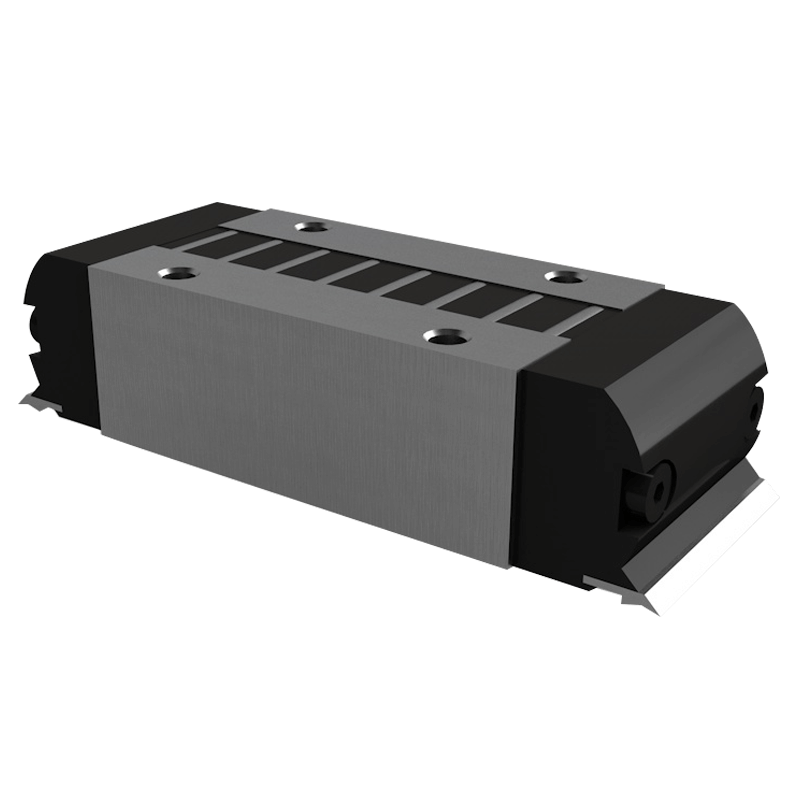

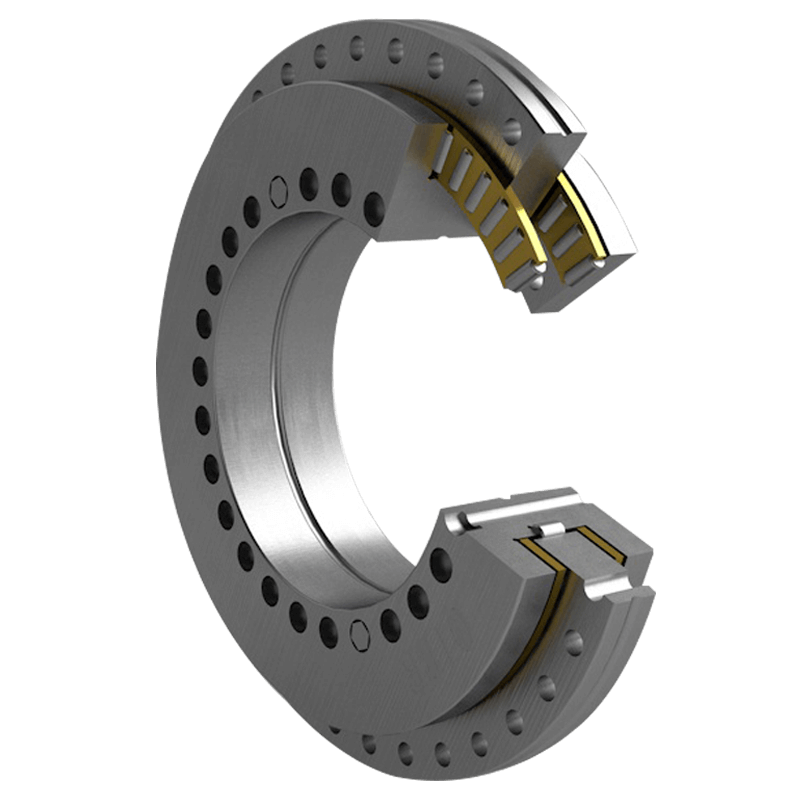

Fault diagnosis and repair of cylindrical roller bearings are important steps to ensure the normal operation of the equipment. Here are some common cylindrical roller bearing failures, diagnostic methods, and repair recommendations:

Bearing Wear: This is the most common problem and is usually caused by prolonged use or insufficient lubrication.

Bearing Overheating: Overheating can be caused by improper bearing lubrication, overloading, or bearing material problems.

Bearing Noise: Abnormal noise is often a sign of bearing damage.

Bearing Vibration: Vibration can indicate bearing or race problems.

Watch and Listen: Monitor the operation of the bearings and note any unusual noise, vibration, or excessive heat.

Check the Condition of Lubrication: Check the condition of the oil or grease to ensure proper lubrication.

Measure the Temperature: Use a thermometer to measure the temperature of the bearing, if it overheats that may have problems.

Check for Vibration: Use a vibration instrument to check the vibration level of the bearing.

Disassembly and Inspection: If necessary, disassemble the bearing for a more thorough inspection.

Replace Bearings: If a bearing is worn or damaged, it must be replaced in time.

Proper Lubrication: Make sure the bearings are properly lubricated, using the correct type and amount of lubricant.

Alignment: If bearing vibration or noise is related to alignment, please make the necessary adjustments.

Check Loading: Make sure bearings are not overloaded to avoid overheating and damage.

Regular Maintenance: Make a regular maintenance schedule that includes cleaning, lubrication, and inspections.

Use Original Parts: If parts need to be replaced, try to use original parts to ensure quality and fit.

Train Operators: Train operators on proper use and maintenance.

Please note that repairing cylindrical roller bearings may require specialized skills and tools. If you're not sure how to perform a repair, it's best to consult a professional technician or repair service provider for help. Timely fault diagnosis and repair can extend the life of bearings and ensure equipment reliability.

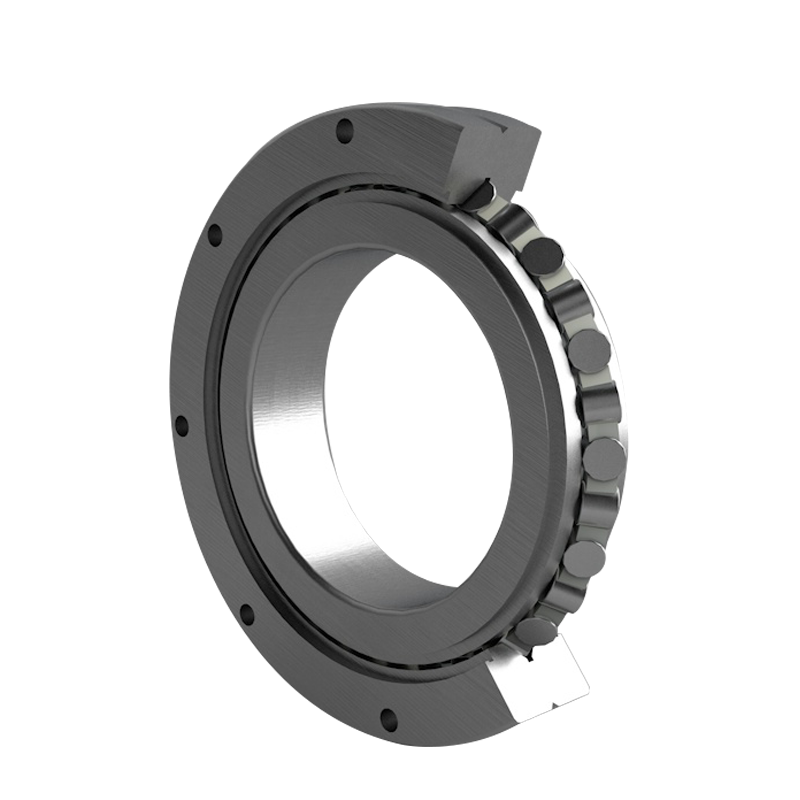

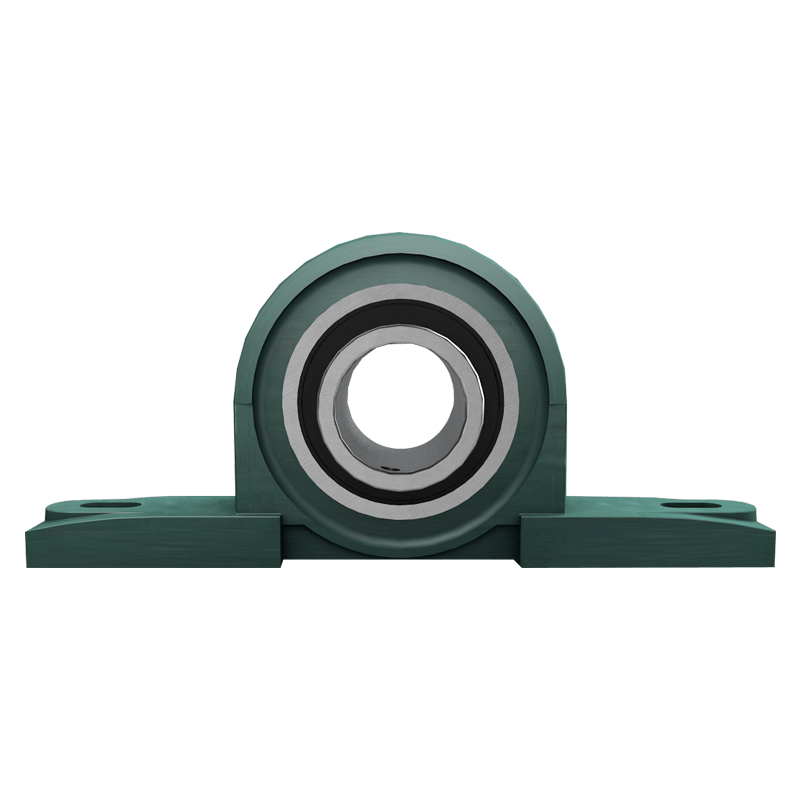

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation