WEBINAR

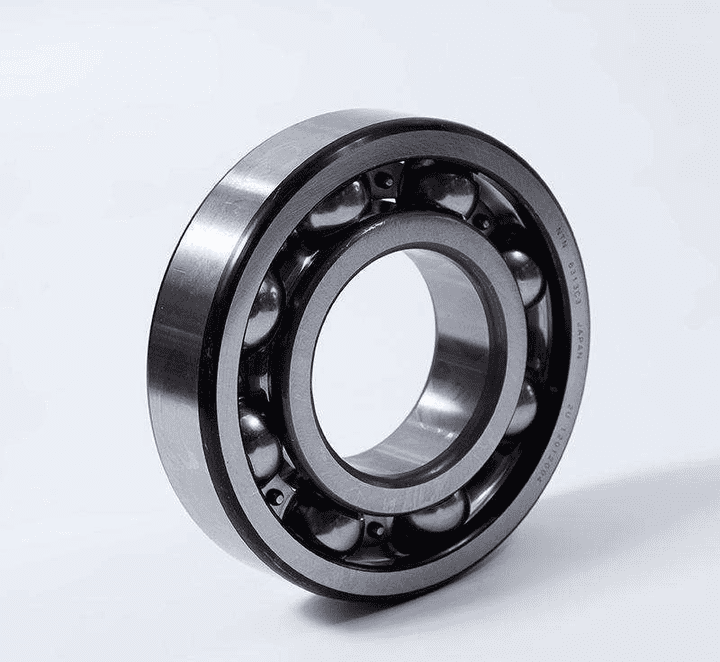

Deep Groove Ball Bearing

Learn More

When using deep groove ball bearings under high temperature environments, which requires special considerations and adjustments to ensure bearing performance and life. High temperatures not only affect the performance of the bearing material, but may also affect lubrication and overall mechanical stability. The following are some key points for using and adjusting deep groove ball bearings under high temperature environments.

High-temperature-resistant Materials: Choose bearing materials that can withstand high-temperature environments, such as high-temperature alloy steel or ceramic materials.

Coefficient of Thermal Expansion: Consider the thermal expansion characteristics of the material to ensure that the bearing maintains proper clearance and fit at high temperatures.

High-temperature Lubricants: Use lubricants suitable for high-temperature conditions. These lubricants should be able to maintain their performance at high temperatures and not decompose or evaporate.

Lubrication Strategy: High temperatures may accelerate lubricant degradation, requiring more frequent lubrication or the use of a longer-lasting lubrication system.

Allow for Larger Clearances: Because high temperatures can cause materials to expand, you may need to allow for larger clearances during installation.

Regular Inspection: Regularly check the bearing clearance to ensure that high temperature operation does not cause excessive wear or the clearance is too small.

Effective Cooling: If possible, use a cooling system to control the temperature of the bearings, especially under extreme high temperature conditions.

Heat Dissipation Design: Ensure sufficient heat dissipation capacity and promote effective heat dissipation through improving the design.

Regular Inspections: Check the condition of bearings regularly, especially in high temperature environments.

Temperature Monitoring: Use temperature sensors or infrared cameras to monitor the temperature of bearings regularly .

When using deep groove ball bearings in high temperature environments, it is necessary to pay attention to material selection, lubrication adjustment, clearance management, cooling and regular maintenance. Through these measures, the reliability and performance of the bearings under high temperature conditions can be ensured, thereby protecting the stable operation of the entire mechanical system.

The effects of high temperatures on deep groove ball bearings are manifold. Correct adjustment and maintenance strategies are key to ensuring the bearings operate effectively under these conditions. Regular monitoring and timely maintenance can significantly reduce the negative impact of high temperature environments on bearings.

WEEYH is jointly formed by China's top agricultural machinery parts factories, focusing on the R&D and production of agricultural machinery parts. About 200,000 sets of agricultural machinery related parts are produced by WEEYH'S factories and sent to the world every year.

We have a top testing laboratory, from material analysis to finished product inspection, each link has a corresponding testing process. More than 30 kinds of testing equipment have built the guarantee of WEEYH safety.

Call for online customer support get FREE BEARING SAMPLE

Online Quotation